Three-dimensional measuring device and method used for large dimension surface

A three-dimensional measurement, large-scale technology, applied in measurement devices, optical devices, instruments, etc., can solve the problem of lack of multi-sensor data integration to provide new ideas, the difficulty of online inspection of large parts and components, and the lack of multi-sensor data. Integrate methods and other issues to achieve the effect of fast measurement speed, solving automation and intelligence level, and flexible structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

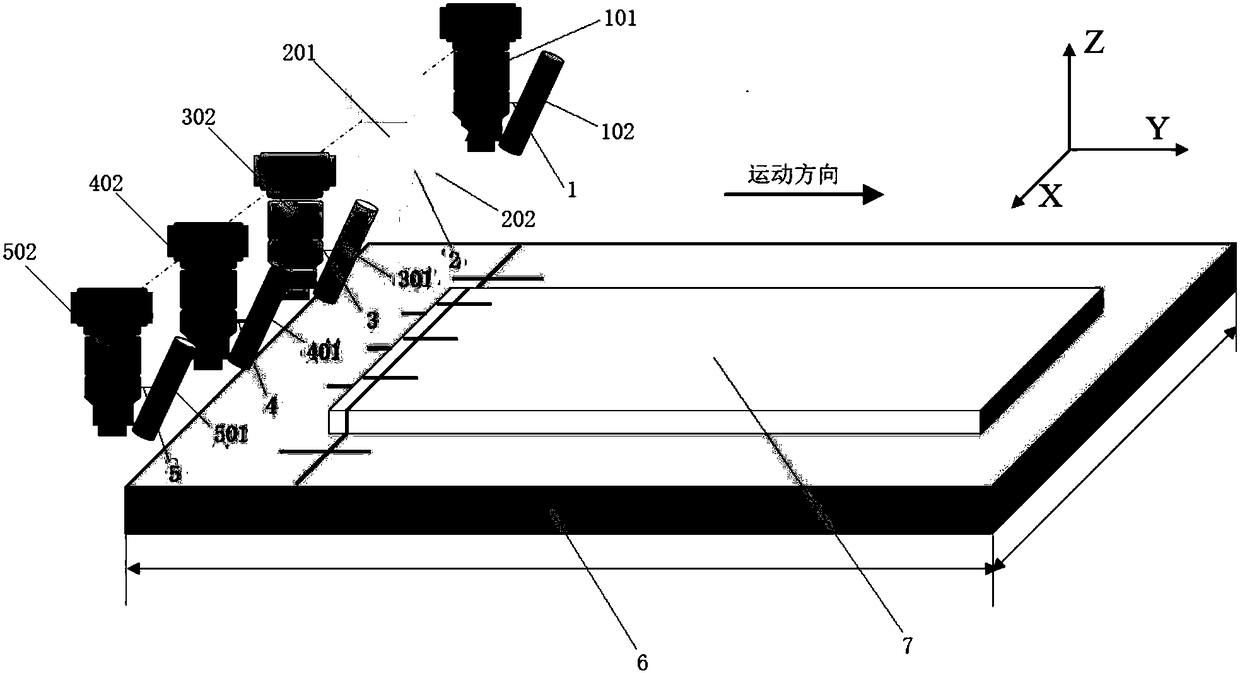

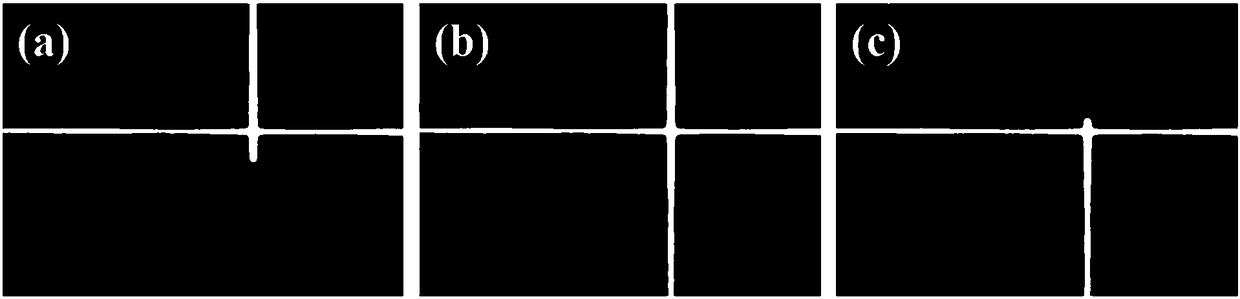

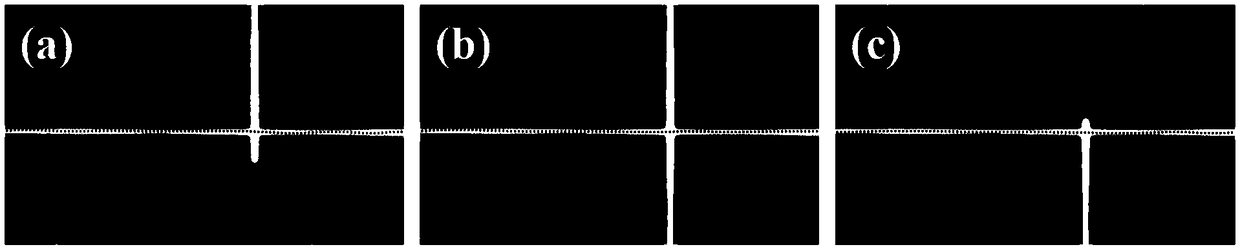

[0039]The invention proposes a detection device based on the cooperative work of multiple triangulation modules and a detection data integration method based on grid division. The specific steps are: use a camera and a cross laser to form a measurement module, fix multiple detection modules in parallel on an adjustable fixture, each detection module is calibrated independently, there is a small amount of overlapping areas between adjacent modules, and the overlapping areas are used to measure adjacent cameras. spacing. The moving frame drives the fixture to move along the length direction of the detection platform. During the moving process, the main control computer obtains the position of the moving frame and triggers the camera to take pictures synchronously; in the cross laser image obtained, the center of the horizontal laser line is extracted by the column-by-column scanning method. combined to determine the sub-pixel laser center on each scanning line; for the laser lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com