Method for testing shearing mechanical characteristic of pile-soil contact surface

A technology of mechanical properties and testing methods, applied in the direction of applying stable shear force to test material strength, strength characteristics, measuring devices, etc., can solve problems such as inability to apply pressure simulation, improve test efficiency, ensure test accuracy, improve Simulate the effect of similarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

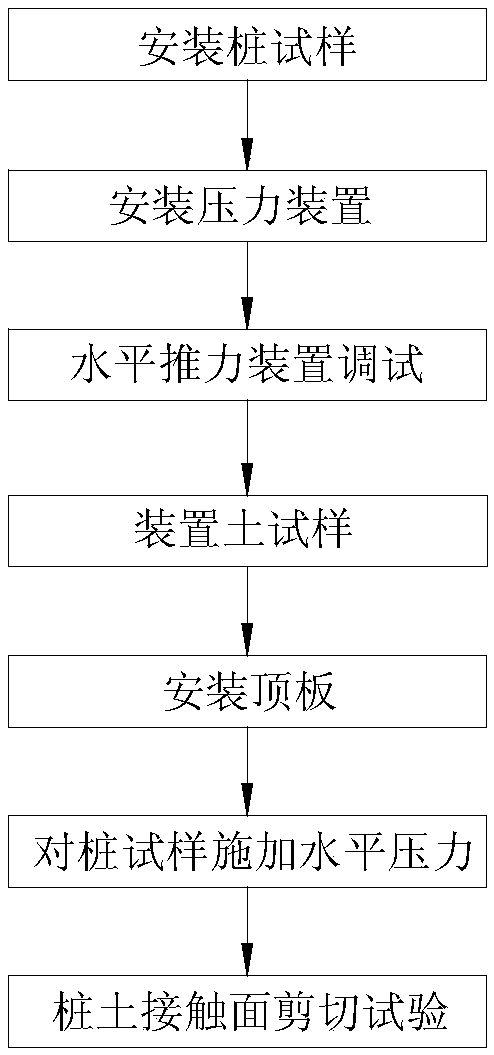

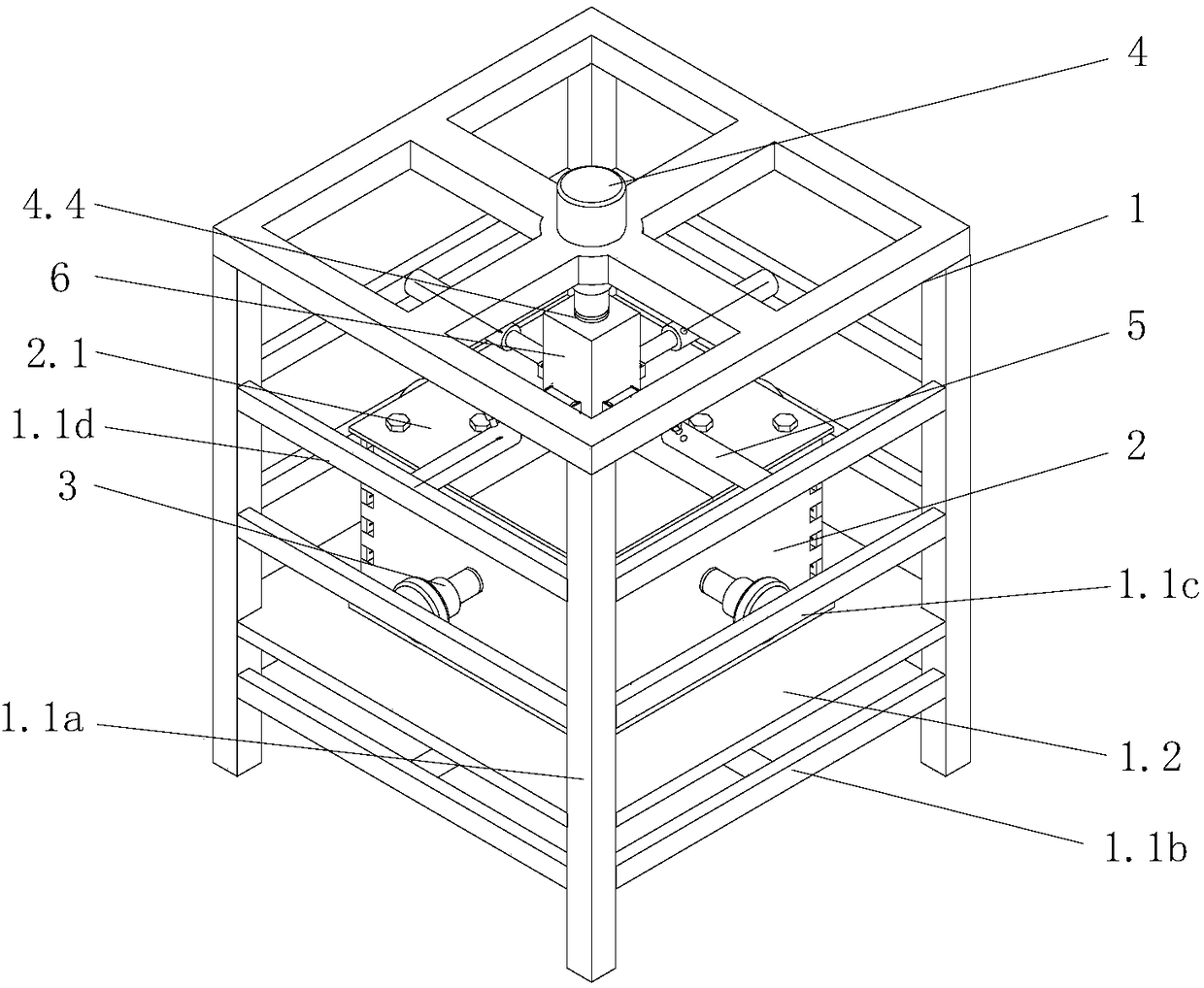

[0046] Such as figure 1 As shown, a method for testing the shear mechanical properties of the pile-soil contact surface of the present invention uses a test device for the shear mechanical properties of the pile-soil contact surface to test, comprising the following steps:

[0047] 1. Install the pile sample: first place the prefabricated pile sample 6 in the compression chamber 2 of the test device, and adjust the horizontal fixing device 5 so that the surface of the roller 5.1 of the horizontal fixing device is close to the outer surface of the pile sample to control There is no horizontal displacement of the pile sample; in this step, pads should be placed at the bottom of the sample pile to prevent the pile from sliding down during installation;

[0048] 2. Install the pressure device: install the pressure device 4 on the reaction force frame 1.3, so that the top of the pile sample is connected to the vertical loading device 4.1 through the vertical dowel bar 4.2, and the ...

Embodiment 2

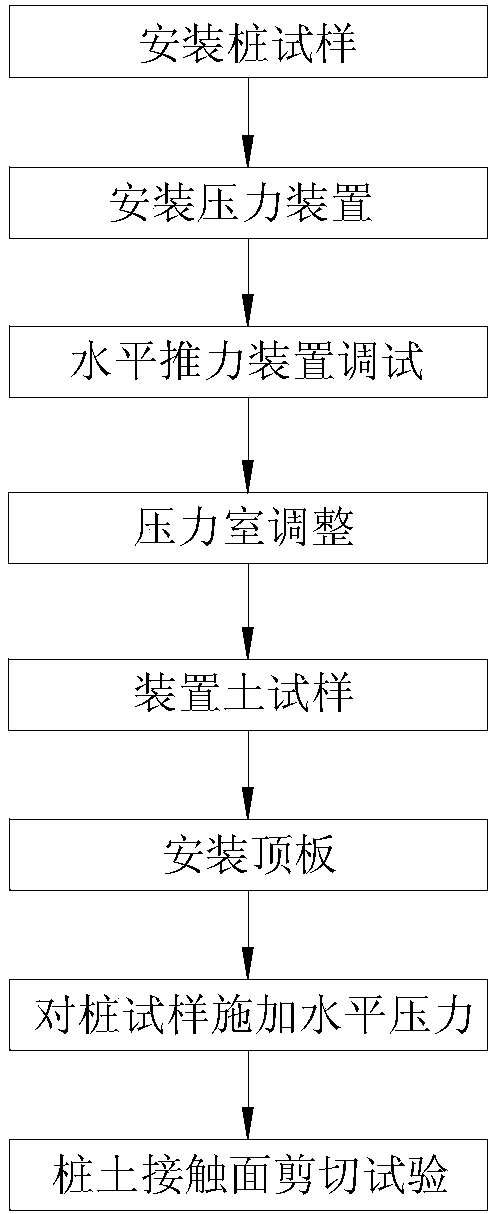

[0063] Such as figure 2 Shown, another kind of pile-soil contact surface shear mechanical property testing method of the present invention comprises the following steps:

[0064] 1. Install the pile sample: first place the prefabricated pile sample 6 in the compression chamber 2 of the test device, and adjust the horizontal fixing device 5 so that the surface of the roller 5.1 of the horizontal fixing device is close to the outer surface of the pile sample to control There is no horizontal displacement of the pile sample; in this step, pads should be placed at the bottom of the sample pile to prevent the pile from sliding down during installation;

[0065] 2. Install the pressure device: install the pressure device 4 on the reaction force frame 1.3, so that the top of the pile sample is connected to the vertical loading device 4.1 through the vertical dowel bar 4.2, and the distance between the pile sample and the vertical dowel bar A displacement sensor A4.3 and a pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com