Full-automatic implanting guide plate production method

A production method and fully automatic technology, applied in 3D image processing, image data processing, instruments, etc., can solve the problems of poor comfort of the guide plate, insufficient smoothness of the edge of the guide plate, and reduced overall grid resolution, etc., to achieve enhanced comfort , Improve the generation efficiency, and the effect of fast groove processing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

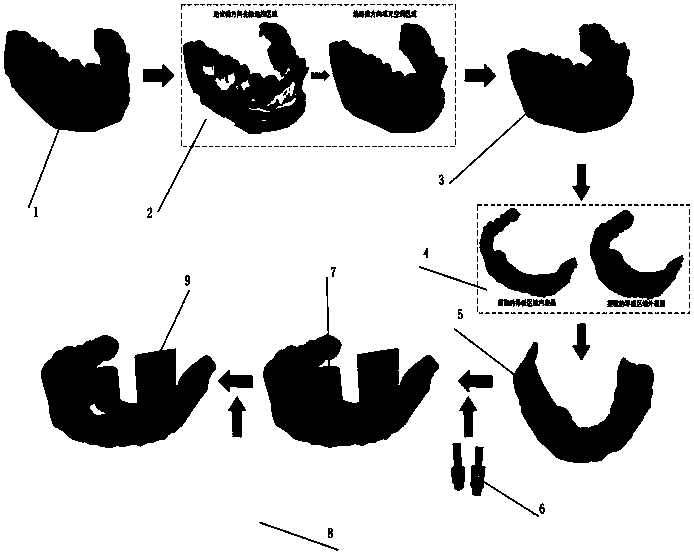

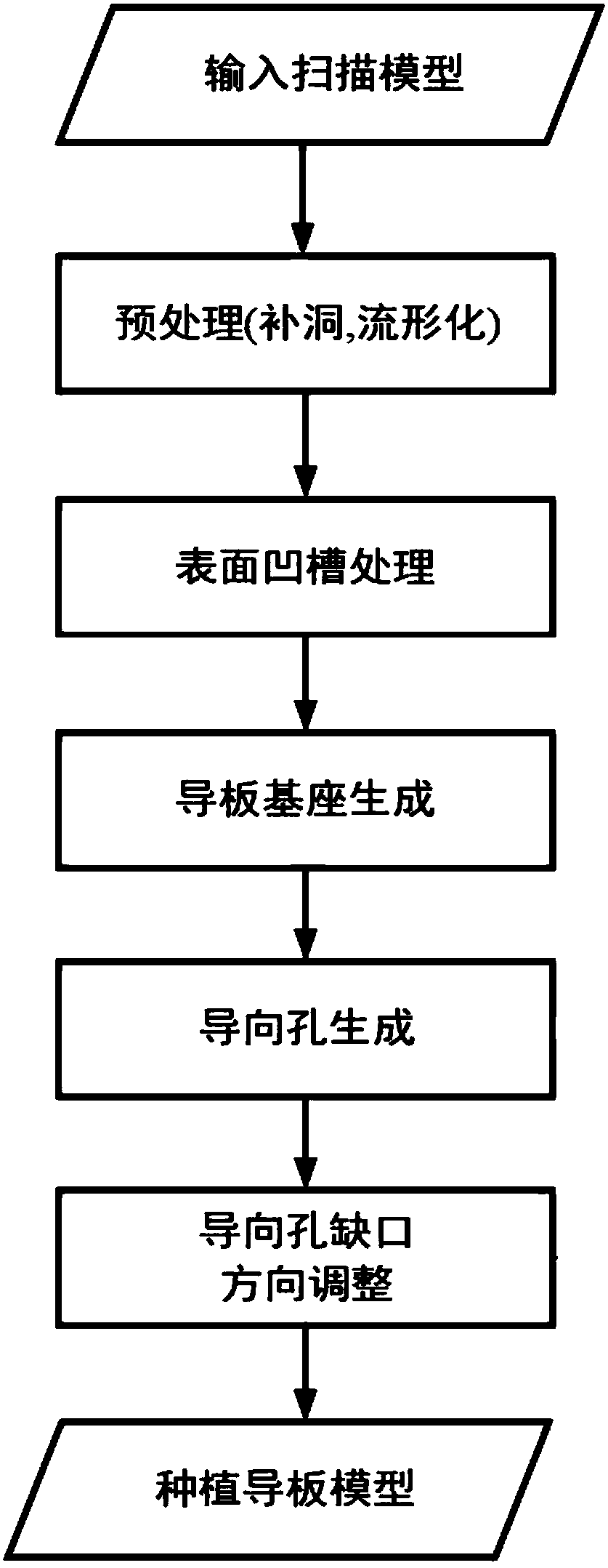

[0047] Such as Figure 1 to Figure 8 Shown: a fully automatic planting guide plate production method,

[0048] Take the following steps,

[0049] Step 1: Read the posture information of the oral scan model, dental arch curve, implant and retainer nails aligned with the CBCT image data, and set the guide plate selection boundary. The oral scan model is generally in stl format;

[0050] Step 2: Perform grid hole filling and manifold preprocessing on the oral scan model to obtain the following: figure 2 The preprocessed grid data graph shown in 1;

[0051] Step 3: Calculate the drafting direction of the scanned model. By choosing an appropriate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com