Novel structural cable and manufacturing method thereof

A technology of a new structure and manufacturing method, which is applied in the direction of cable/conductor manufacturing, insulating cables, insulating conductors/cables, etc., can solve the problem of large influence of cable current output, and achieve the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

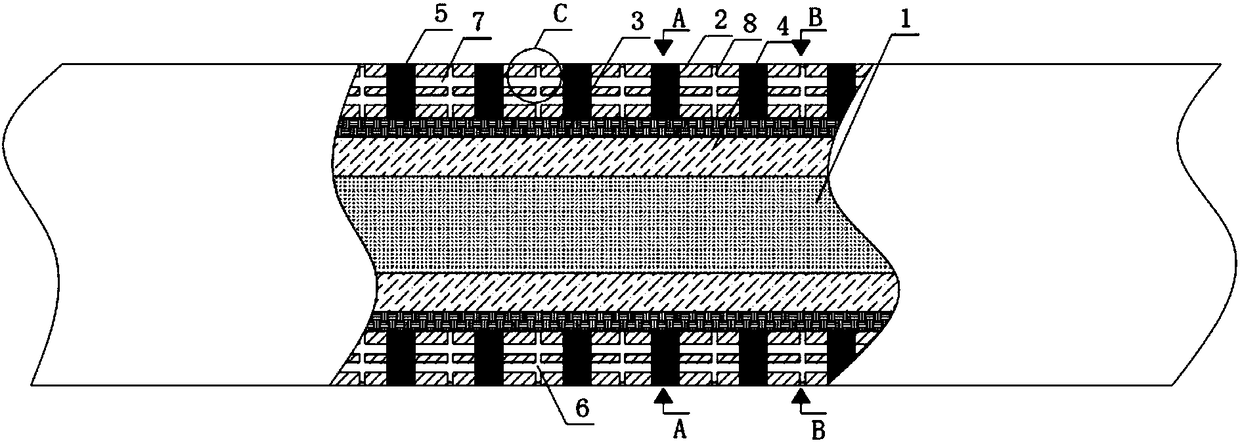

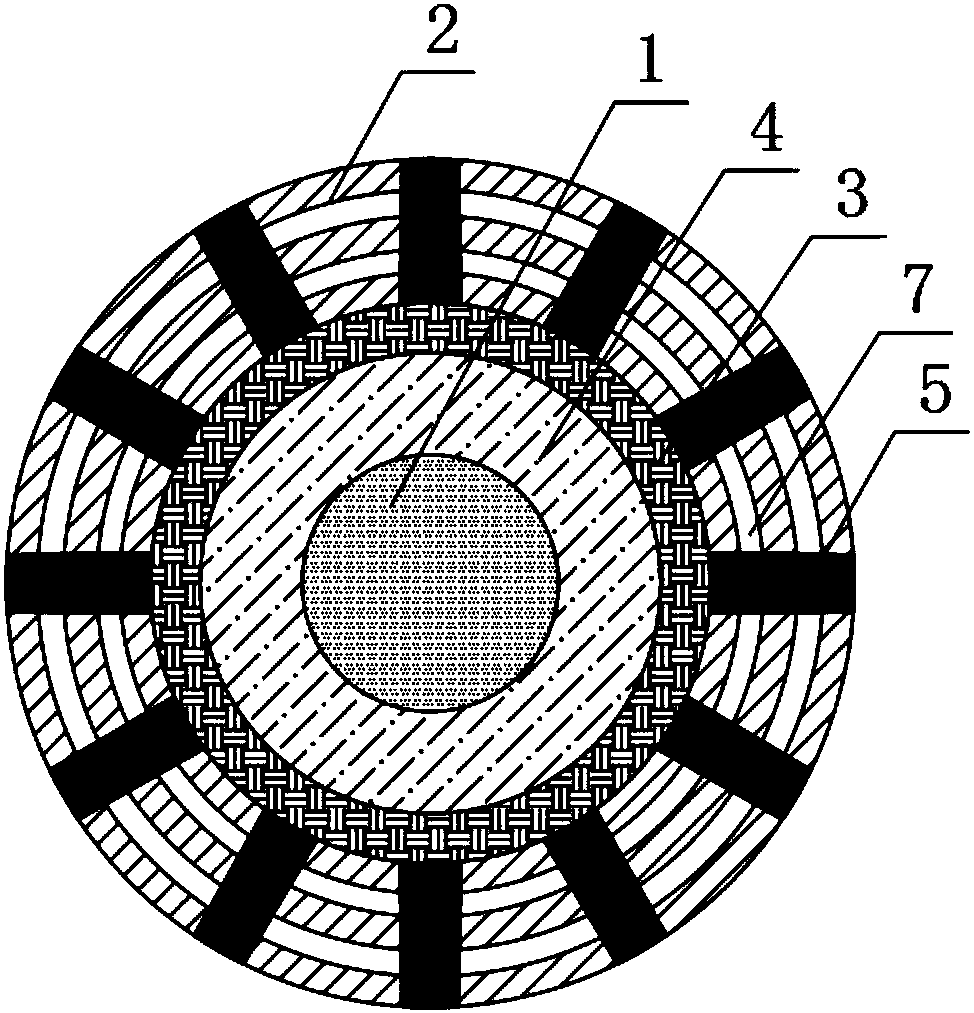

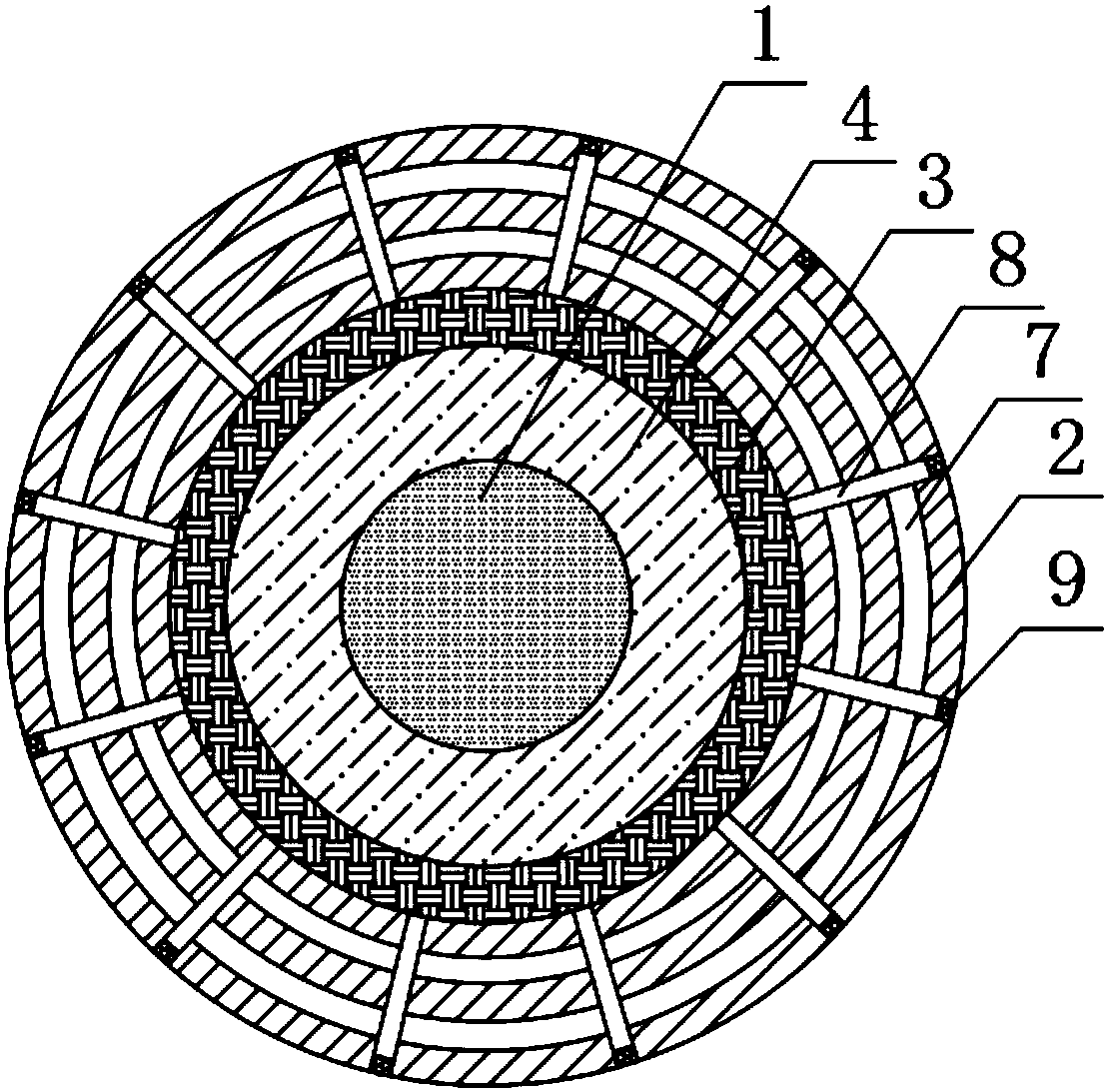

[0028] according to Figure 1-4 A new type of structural cable is shown, including a conductor 1 and an insulating layer 2, the insulating layer 2 is arranged around the outer wall of the conductor 1, and the inner wall of the insulating layer 2 is fixed and surrounded by a sealing layer 3, through which the sealing layer 3 The setting can not only make the filling layer 4 achieve a sealed environment, prevent the inert gas in the filling layer 4 from overflowing, but also conduct heat conduction to the heat emitted by the conductor 1, and at the same time, it can also achieve the effect of passing the current through the conductor 1. The effect of insulation, the filling layer 4 is arranged between the sealing layer 3 and the conductor 1, through the setting of the filling layer 4, the stability of the inert gas is used to avoid the direct contact of the sealing layer 3 with the conductor 1, and the sealing layer 3 is avoided. The aging phenomenon occurs under the electric fi...

Embodiment 2

[0031] The present invention also provides a manufacturing method of a novel structural cable, the specific operation steps of which are as follows:

[0032] Step 1: Material preparation: Prepare sufficient materials, extruders and grinders for cable manufacturing in advance;

[0033] Step 2: Extrusion: First, uniformly extrude the sealing layer 3 on the outer wall side of the conductor 1, so that the thickness of the extruded sealing layer 3 is set between 1 mm and 3 mm, and leave a gap between the conductor 1 and the sealing layer 3. There is a distance of 4mm~6mm, and one end of the filling layer 4 is sealed, and the other end is not sealed first, and then the thermal conduction column 5 is fixed on the outer wall side of the sealing layer 3 by an adhesive, and then the sealing layer 3 is sealed by an extruder. The insulating layer 2 is uniformly extruded around one side of the outer wall, and when the insulating layer 2 is extruded, the heat exchanging hole 6 is used to le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com