Process for manufacturing memory card

A manufacturing method and technology for memory cards, which are applied to record carriers, instruments, and computer parts used in machines, can solve the problems of cumbersome assembly procedures, increased defect rate, and cumbersome manufacturing processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

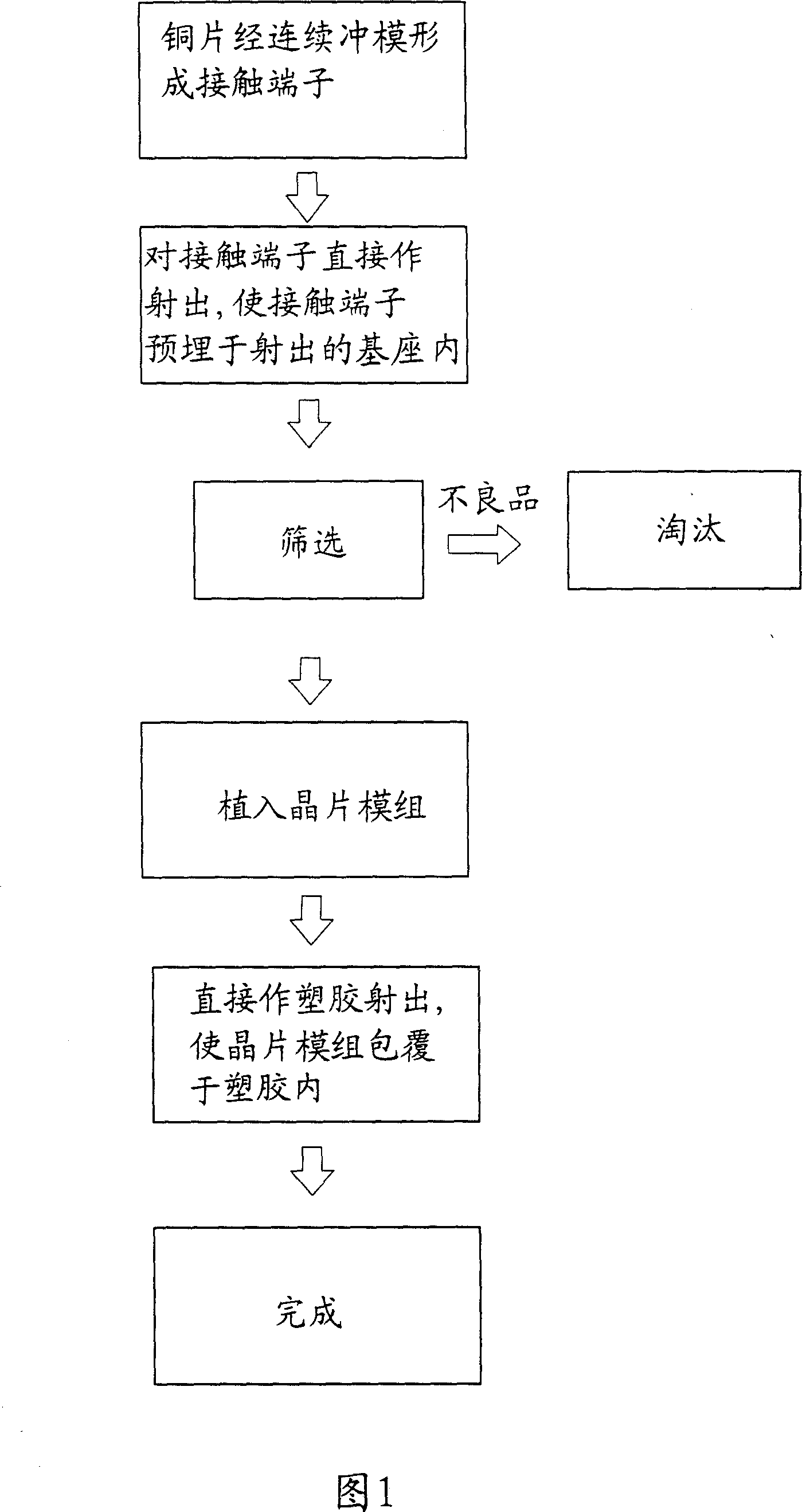

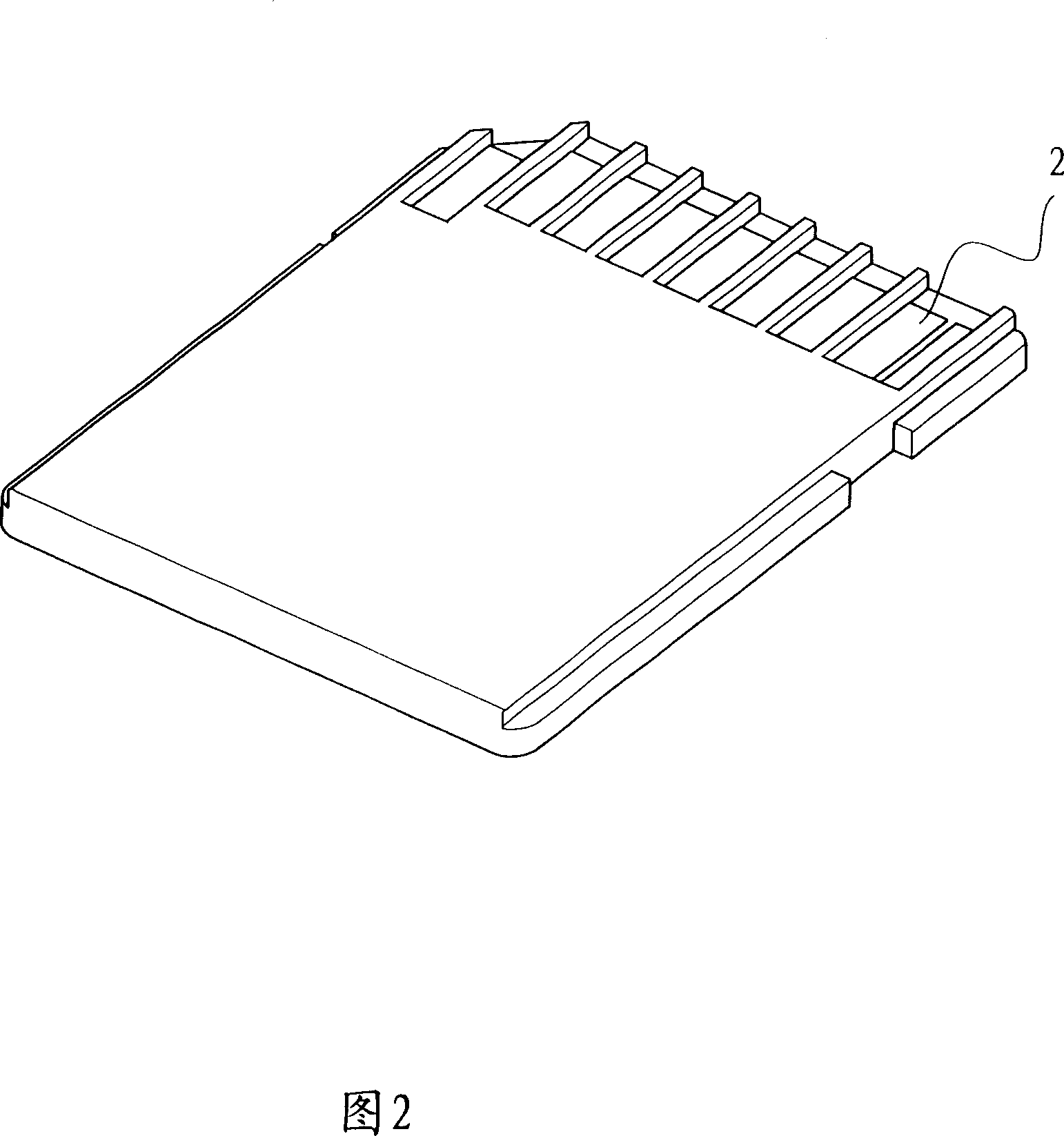

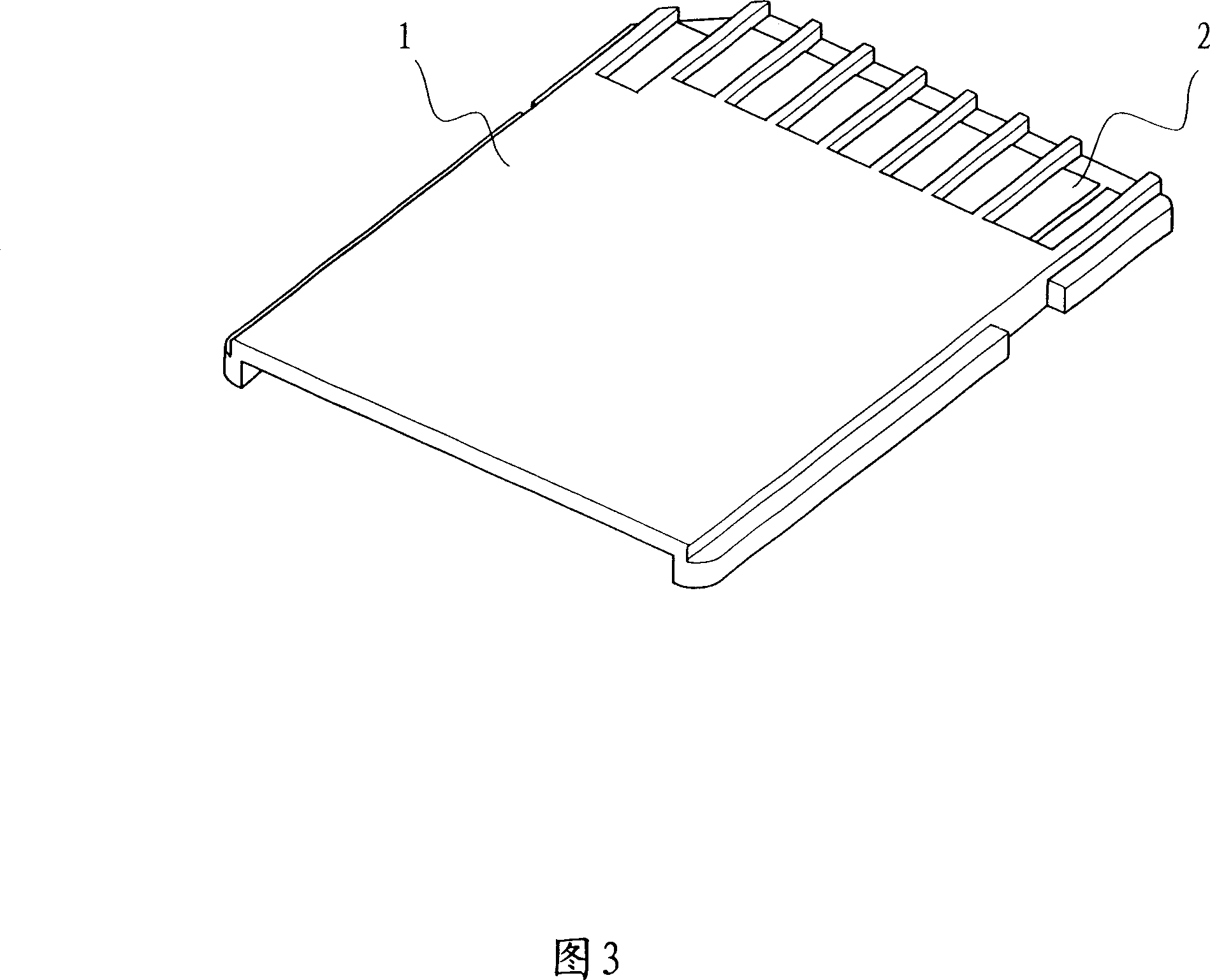

[0021] Fig. 1 is a production flowchart of a preferred embodiment of the present invention, and with reference to other figures, it can be clearly known that the memory card of the present invention (as shown in Fig. The chip module 3 (including flash memory, control chip, and passive components) on the base 1 forms a circuit connection with the contact terminal 2 at the front end of the base 1 . The main improvement process of the present invention is:

[0022] The contact terminal 2 formed by the continuous punching of the copper sheet is directly injected on the plastic injection machine after the molding, so that the contact terminal 2 is pre-embedded in the injection molded base 1 (as shown in Figure 3) , this manufacturing method can save the manual assembly of the base 1 and the contact terminal 2, thus simplifying the manufacturing process and further reducing the manufacturing cost. After this stage is completed, the semi-finished products with poor injection are scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com