A kind of electrical insulation high temperature resistant hybrid ball bearing and its preparation method

A high-temperature-resistant, mixed ball technology, used in shafts and bearings, bearing components, mechanical equipment, etc., can solve problems such as unfavorable industrialized mass production, easy wear and tear of coatings, decay and blackening of grease, etc., to ensure reliable normal operation. good insulation effect and small friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

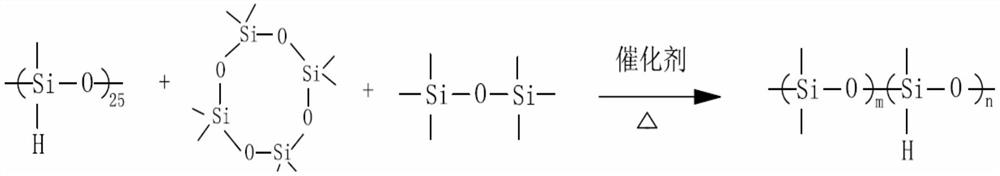

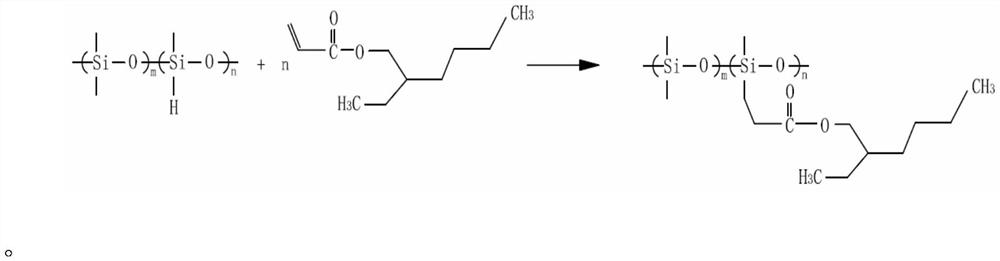

[0038] An electrically insulated and high temperature resistant hybrid ball bearing, comprising an outer ring, an inner ring, a retainer and a set of rolling elements, an outer raceway is provided on the inner wall of the outer ring, and an inner raceway is provided on the outer wall of the inner ring. The outer raceway and the inner raceway are arc-shaped grooves, the retainer is made of polyether ether ketone, the rolling elements are silicon nitride ceramic balls, and the retainer is sprayed with a layer of The solid side chain contains isooctyl acrylate modified silicone lubricating material layer, and its structural formula is:

[0039] Wherein, m=80, n=50.

[0040] A method for preparing an electrically insulating and high temperature resistant hybrid ball bearing, comprising the following steps:

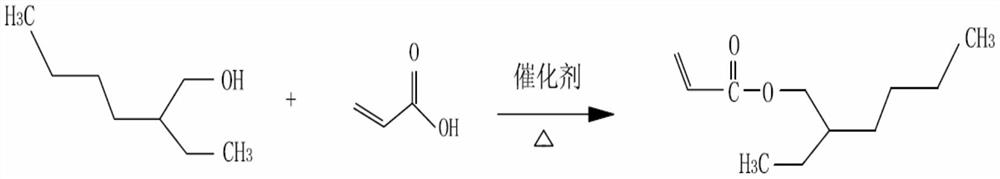

[0041](1) Add acrylic acid, isooctyl alcohol and p-toluenesulfonic acid catalysts in the reaction kettle A equipped with a reflux device and a stirring device, and stop the...

Embodiment 2

[0055] An electrical insulation and high temperature resistant hybrid ball bearing, comprising an outer ring, an inner ring, a retainer and a set of rolling elements, the inner wall of the outer ring is provided with an outer raceway, the outer wall of the inner ring is provided with an inner raceway, the The outer raceway and the inner raceway are arc-shaped grooves, the retainer is made of polyether ether ketone, the rolling elements are silicon nitride ceramic balls, and the retainer is sprayed with a layer of The solid side chain contains isooctyl acrylate modified silicone lubricating material layer, and its structural formula is:

[0056] Among them, m=88, n=75.

[0057] A method for preparing an electrically insulating and high temperature resistant hybrid ball bearing, comprising the following steps:

[0058] (1) Add the catalyst of acrylic acid, isooctyl alcohol and p-toluenesulfonic acid into the reaction kettle A equipped with a reflux device and a stirring devic...

Embodiment 3

[0072] An electrical insulation and high temperature resistant hybrid ball bearing, comprising an outer ring, an inner ring, a retainer and a set of rolling elements, the inner wall of the outer ring is provided with an outer raceway, the outer wall of the inner ring is provided with an inner raceway, the The outer raceway and the inner raceway are arc-shaped grooves, the retainer is made of polyether ether ketone, the rolling elements are silicon nitride ceramic balls, and the retainer is sprayed with a layer of The solid side chain contains isooctyl acrylate modified silicone lubricating material layer, and its structural formula is:

[0073] Wherein, m=102, n=75.

[0074] A method for preparing an electrically insulating and high temperature resistant hybrid ball bearing, comprising the following steps:

[0075] (1) Add acrylic acid, isooctyl alcohol and p-toluenesulfonic acid catalysts into reactor A equipped with a reflux device and a stirring device, react at 120°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com