Insulating winding device for steel cable and manufacturing process of winding drum assembly

A hoisting device and hoisting drum technology, applied in the direction of hoisting device, spring mechanism, etc., can solve problems such as lack of insulation and inability to make large-scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

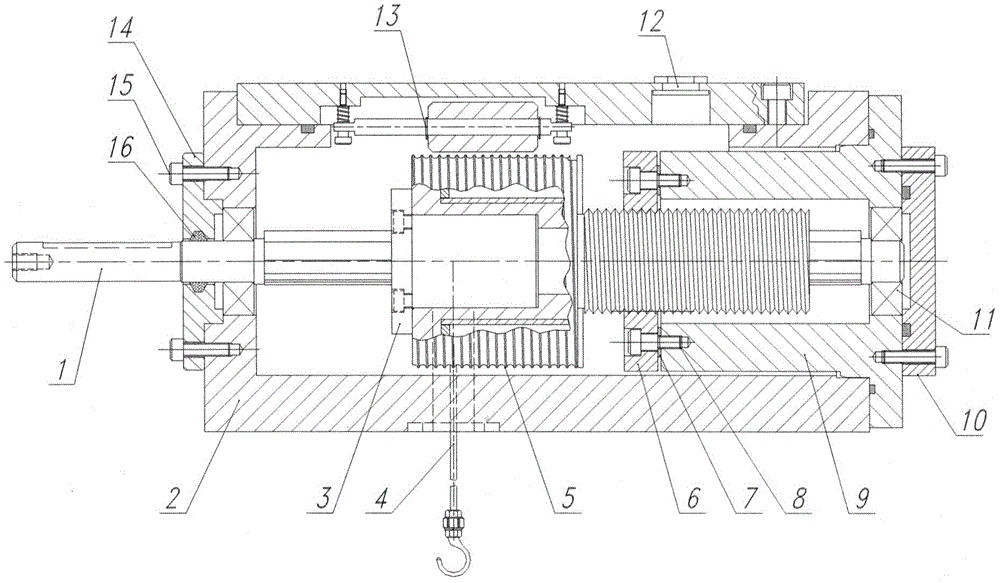

[0018] Such as figure 1 As shown, the insulated cable hoisting device includes a driving shaft 1, a chamber 2, a splined auxiliary flange 3, a steel cable 4, a hoisting drum assembly 5, a guide nut 6, an adjusting ring 7, a screw 8, and a nut supporting cylinder 9 , shaft end cover 10, bearing 11, plug 12, elastic roller assembly 13, bearing gland 14, screw 15, shaft seal 16; chamber 2 is equipped with spline auxiliary flange 3, winch assembly 5, guide nut 6. Adjusting ring 7 and nut support cylinder 9, plug 12 and elastic roller assembly 13 are installed on the upper part of chamber 2, shaft end cover 10, bearing gland 14 and shaft seal 16 are installed at both ends of chamber 2, and the drive shaft 1 is equipped with a spline auxiliary flange 3 and a winch assembly 5, the spline auxiliary flange 3 and the hoist assembly 5 are fastened together by screws, and are guided along the spline groove on the drive shaft 1 by the built-in ball , to make axial movement, one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com