Colloidal power lead-acid battery inner formation process

A lead-acid battery, internalization technology, applied in the direction of lead-acid battery, lead-acid battery construction, secondary battery, etc., can solve the problems of affecting battery performance, difficult to penetrate, high energy consumption, etc., to improve competitiveness and fully convert , Improving the effect of forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

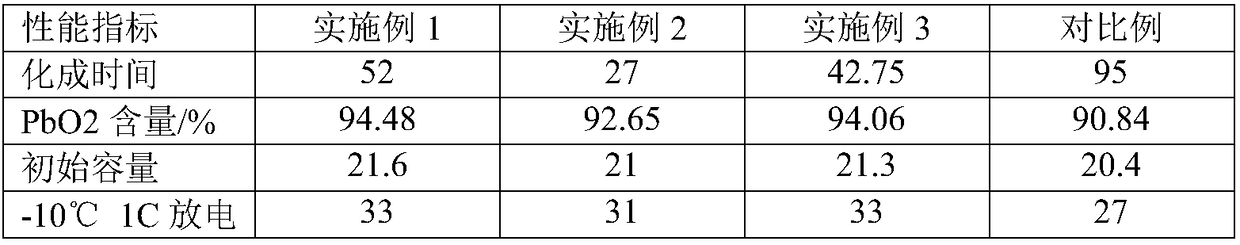

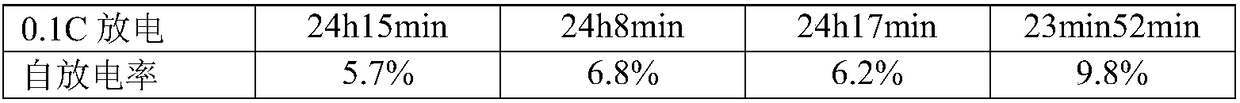

Embodiment 1

[0039] Add colloidal electrolyte to the battery: first use concentrated sulfuric acid, pure water (conductivity less than 2μS / cm), sodium sulfate, and stannous sulfate to form an electrolyte with a mass fraction of sulfuric acid of 37.5%, sodium sulfate of 1.5%, and stannous sulfate of 0.5%. , and then add gas-phase silica while cutting to configure a colloidal electrolyte with a colloidal concentration of 2.5% and a sulfuric acid electrolyte density of 1.250-1.260g / ml. The configured colloidal electrolyte is added to the battery by vacuum perfusion, and the 0.5h, the temperature of the battery is controlled at 25°C, and the formation procedure includes the following steps in sequence:

[0040] (1) First charging stage: first charge with 0.1C current for 5 hours, and then charge with 0.15C current for 5 hours; the first charging stage is to charge 1.25 times the rated capacity;

[0041] (2) First discharge stage: discharge with 0.1C current for 1h;

[0042] (3) Second charge ...

Embodiment 2

[0062] Add colloidal electrolyte into the battery, let it stand for 1 hour, control the temperature of the battery at 30°C, and the formation procedure includes the following steps in sequence:

[0063] (1) First charging stage: first charge with 0.15C current for 3 hours, then charge with 0.2C current for 3 hours; the first charging stage is to charge 1.05 times the rated capacity;

[0064] (2) First discharge stage: discharge with 0.2C current for 0.5h;

[0065] (3) Second charge stage: charge with 0.2C current for 3h;

[0066] (4) Second discharge stage: discharge with 0.2C current for 0.5h;

[0067] (5) Three charging stages: charging with 0.25C current for 2h;

[0068] (6) Three discharge stage: discharge with 0.2C current for 0.5h;

[0069] (7) Four charging stage: charging with 0.3C current for 2h;

[0070] (8) Four discharge stage: discharge with 0.2C current for 0.5h;

[0071] (9) Five charging stage: charging with 0.35C current for 2h;

[0072] (10) Five-discharg...

Embodiment 3

[0085] Add colloidal electrolyte into the battery, let it stand for 0.75h, control the temperature of the battery at 45°C, and the formation procedure includes the following steps in sequence:

[0086] (1) First charging stage: first charge with 0.125C current for 4 hours, and then charge with 0.15C current for 3 hours; the first charging stage is to charge 0.95 times the rated capacity;

[0087] (2) First discharge stage: discharge with 0.1C current for 0.75h;

[0088] (3) Second charge stage: charge with 0.175 current for 3 hours;

[0089] (4) Second discharge stage: discharge with 0.15C current for 0.5h;

[0090] (5) Three charging stages: charge with 0.2C current for 4h;

[0091] (6) Three discharge stage: discharge with 0.15C current for 0.5h;

[0092] (7) Four charging stage: charge with 0.25C current for 4h;

[0093] (8) Four discharge stage: discharge with 0.15C current for 0.5h;

[0094] (9) Five charging stage: charge with 0.35C current for 4h;

[0095] (10) Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com