Brushless DC motor for screw driver

A brush DC motor and screwdriver technology, applied in the field of brushless DC motors for screwdrivers, can solve problems such as high labor intensity, poor positioning accuracy, and inconvenient maintenance, and achieve improved heat dissipation, extended service life, and easy connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

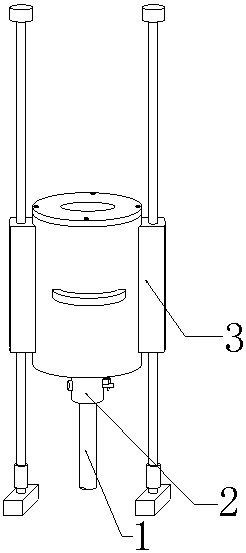

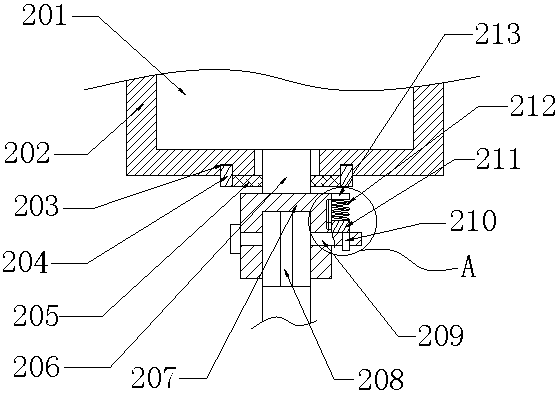

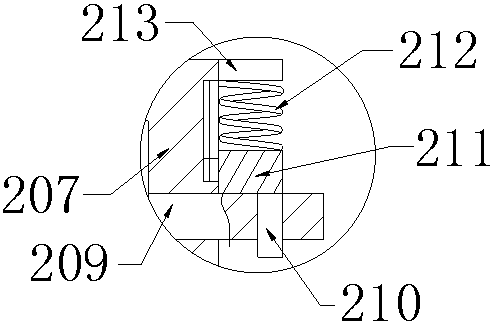

[0022] see Figure 1-Figure 5 , the present invention provides a technical solution: a brushless DC motor for a screwdriver 1, including a screwdriver 1, a connecting component 2 and an auxiliary component 3, the auxiliary component 3 is installed on the connecting component 2, and the screwdriver 1 is connected to the lower end of the connecting component 2 , the connecting assembly 2 includes a motor body 201, a mounting shell 202, a card slot 203, a snap ring 204, a sealing ring 205, a motor shaft 206, a connecting sleeve 207, a connecting head 208, a connecting pin 209, a round rod 210, a limit block 211, Spring 212 and fixed plate 213, auxiliary assembly 3 includes cooling vent 301, concave strip 302, miniature cooling fan 303, bump 304, end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com