Heat dissipation cycle structure

A circulation structure and heat dissipation unit technology, which is applied in the construction parts of electrical equipment, cooling/ventilation/heating transformation, electrical components, etc., can solve the problems of gas retention, exhaustion, poor heat dissipation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described according to the preferred embodiments of the accompanying drawings.

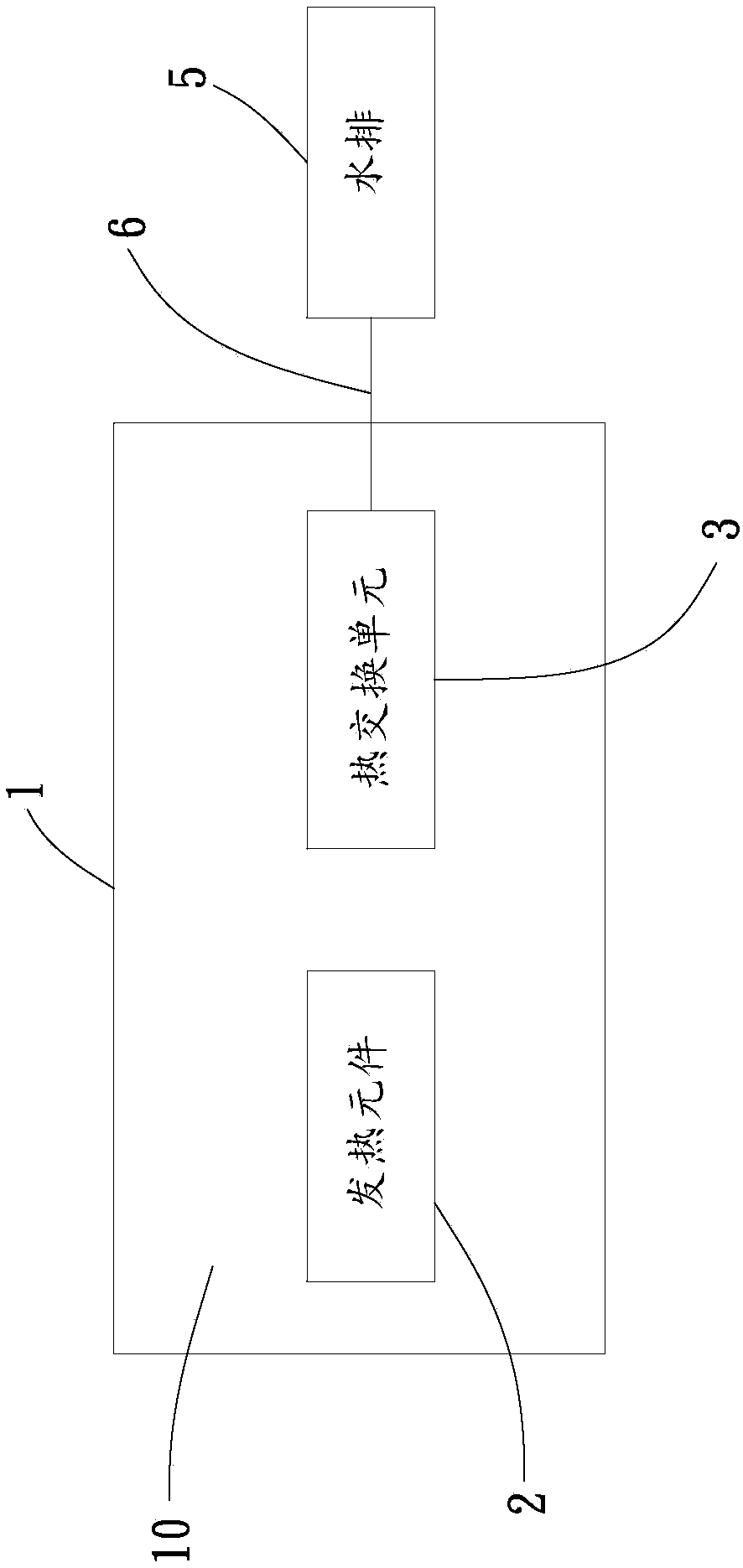

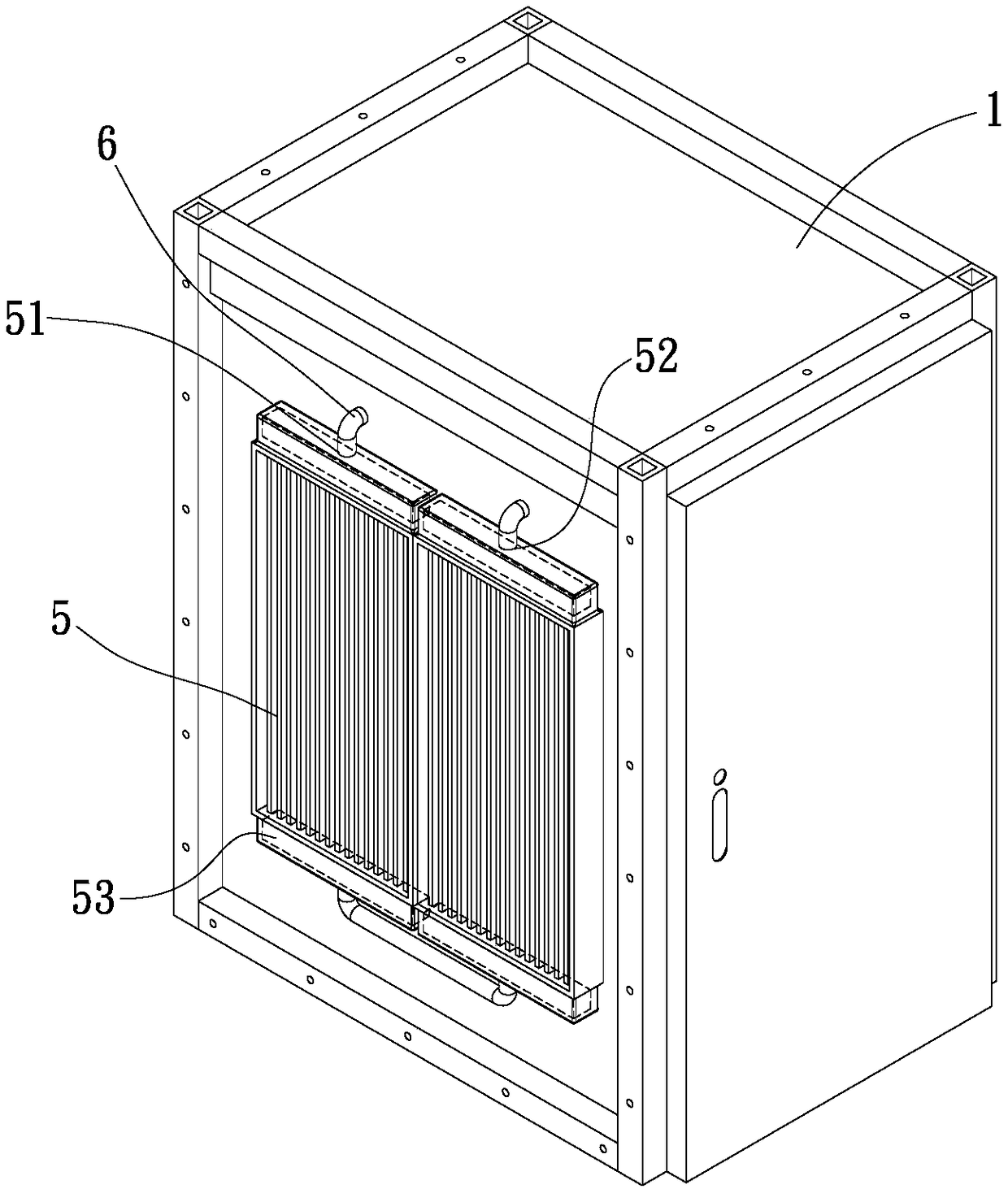

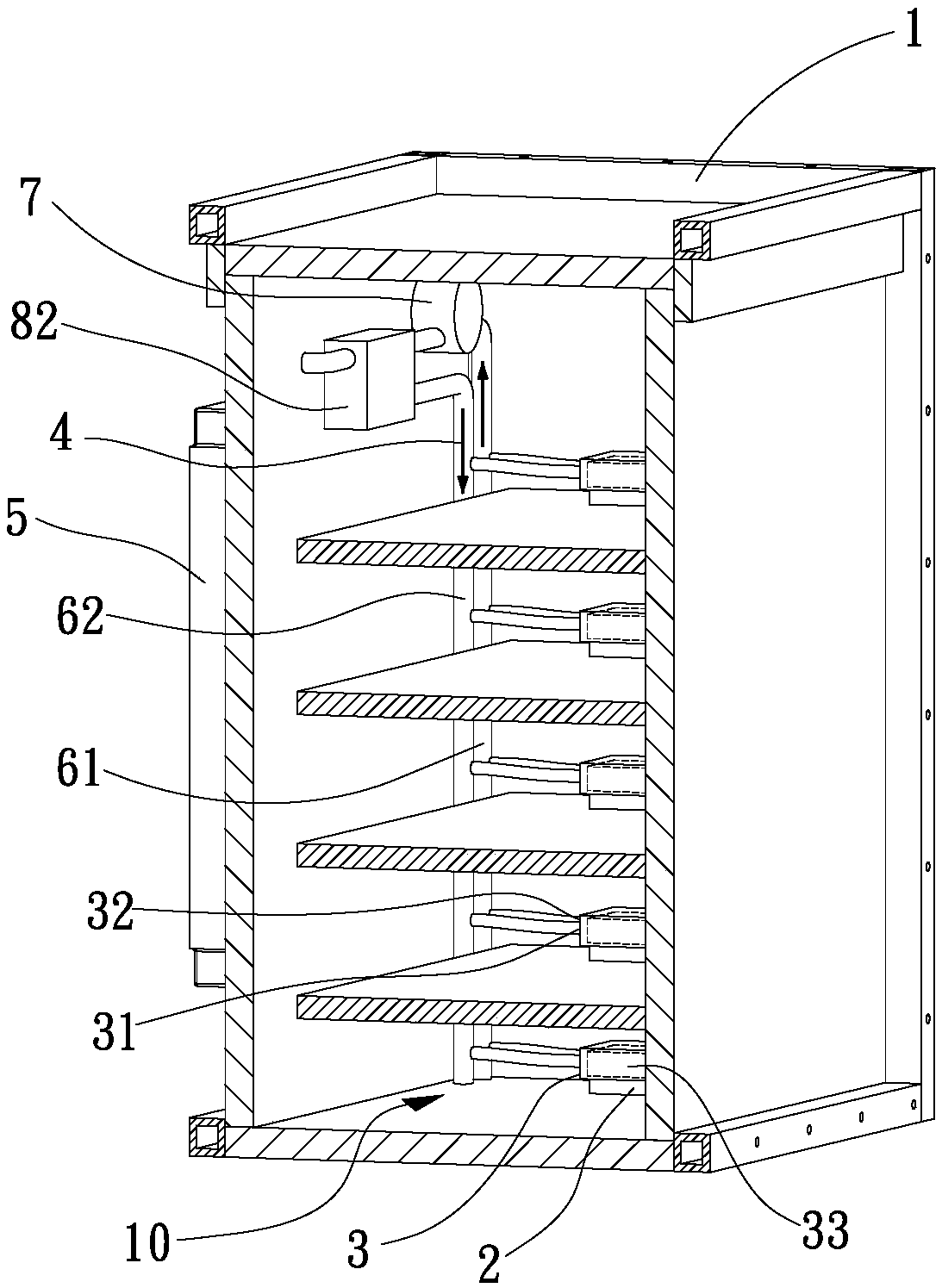

[0033] see figure 1 , figure 2 , image 3 , is a schematic block diagram, a three-dimensional combination view and a three-dimensional sectional view of the first embodiment of the heat dissipation cycle structure of the present invention. As shown in the figure, a heat dissipation cycle structure includes a body 1, at least one heat exchange unit 3, at least one water row 5 and at least one pump 7, the main body 1 has a closed accommodation space 10 to accommodate at least one heating element 2, in this embodiment, the main body 1 is a Chassis or cabinet (such as server cabinet, computer case (such as Figure 4 shown), etc.) for illustration, but not limited thereto, that is, any body 1 with a closed accommodation space 10 is provided with a heat generating element 2 (such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com