Oxalate deposited slurry filtering device

A filter device, oxalate technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

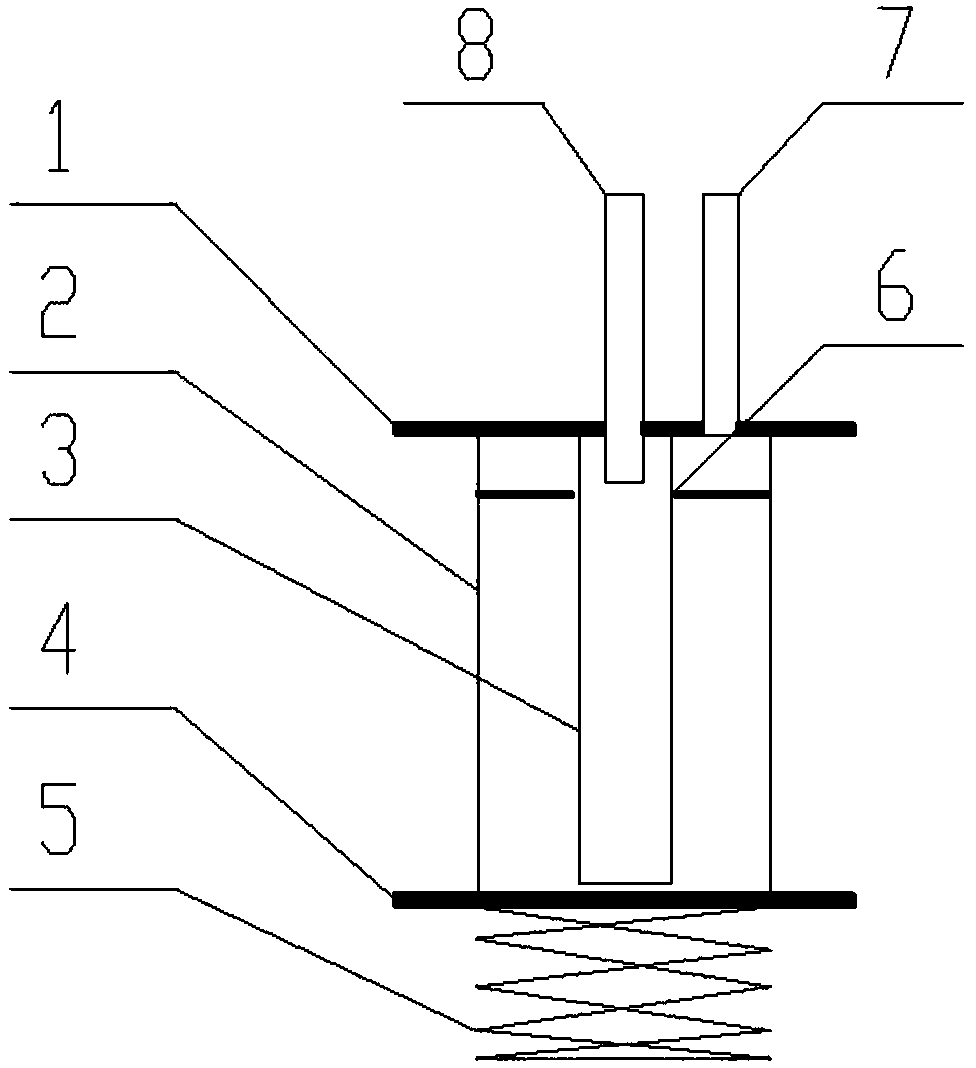

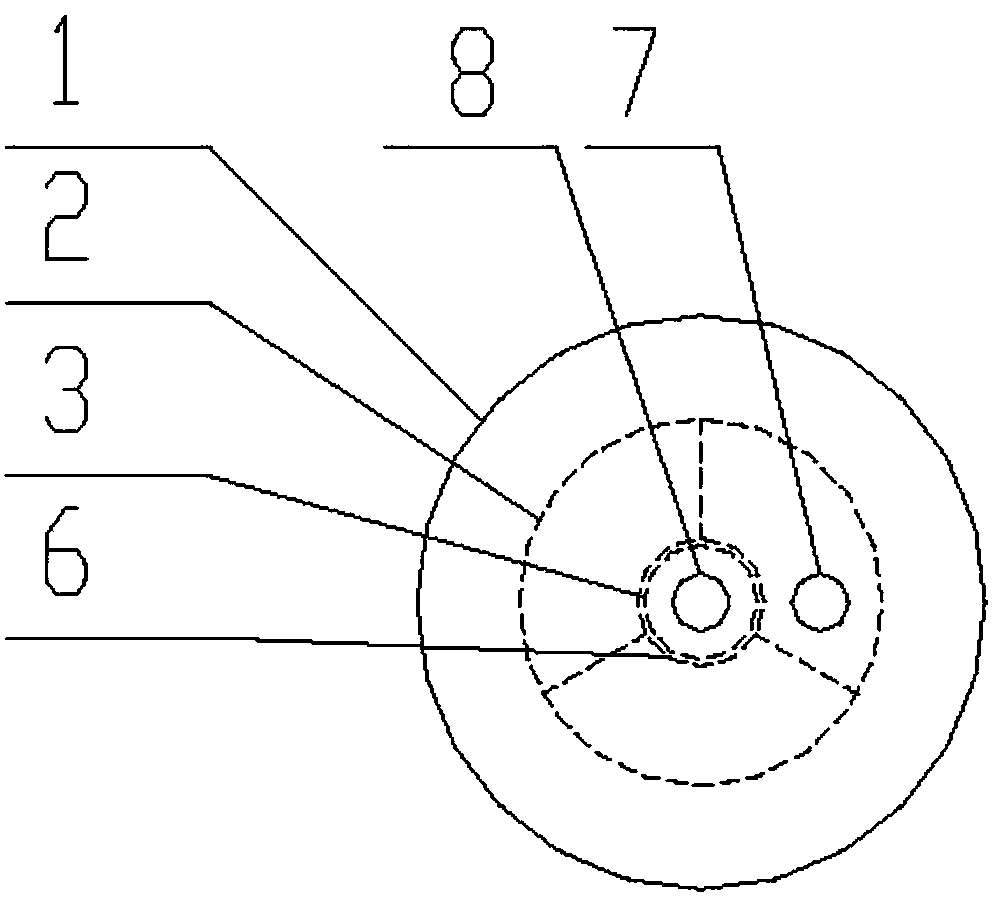

[0022] The structure of the exemplary oxalate precipitation slurry filter device of the present invention is as follows: Figure 1-2 As shown, it includes a top cover 1, a filter cup 2, a filter cartridge 3, a lifting table 4, a lifting and pressing mechanism 5, a scraper 6, an oxalate precipitation slurry inlet pipe 7, and a filtrate outlet pipe 8.

[0023] The filter cup 2 is placed on the lifting platform 4 as a filter chamber, and the lifting platform 4 is placed on the lifting and pressing mechanism 5 tops. The upper part of the filter cup 2 is sealed with a disc-shaped top cover 1 made of stainless steel.

[0024] As a filter material, a filter cartridge 3 made of sintered stainless steel is placed in the filter cup 2 for separating the oxalate precipitate filter cake (attached to the outer wall of the filter cartridge 3) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com