Battery assembly and electric vehicle thereof

A technology of battery components and electric vehicles, which is applied in the direction of electric vehicles, battery pack components, electric vehicle charging technology, etc., can solve the problems of inability to make breakthroughs in improving battery life, no breakthroughs in batteries, and low storage capacity, etc., to achieve improved The effect of battery life, improved life, and good braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

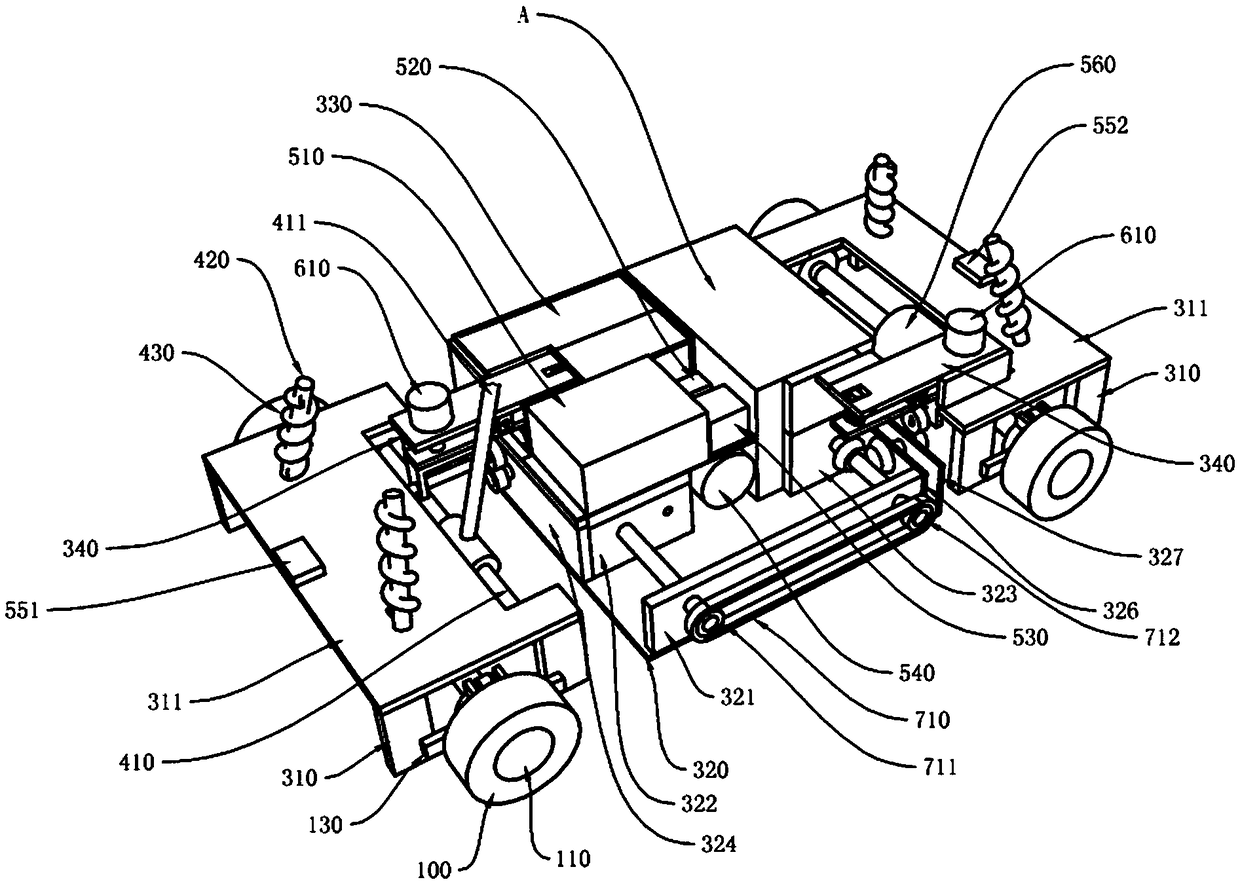

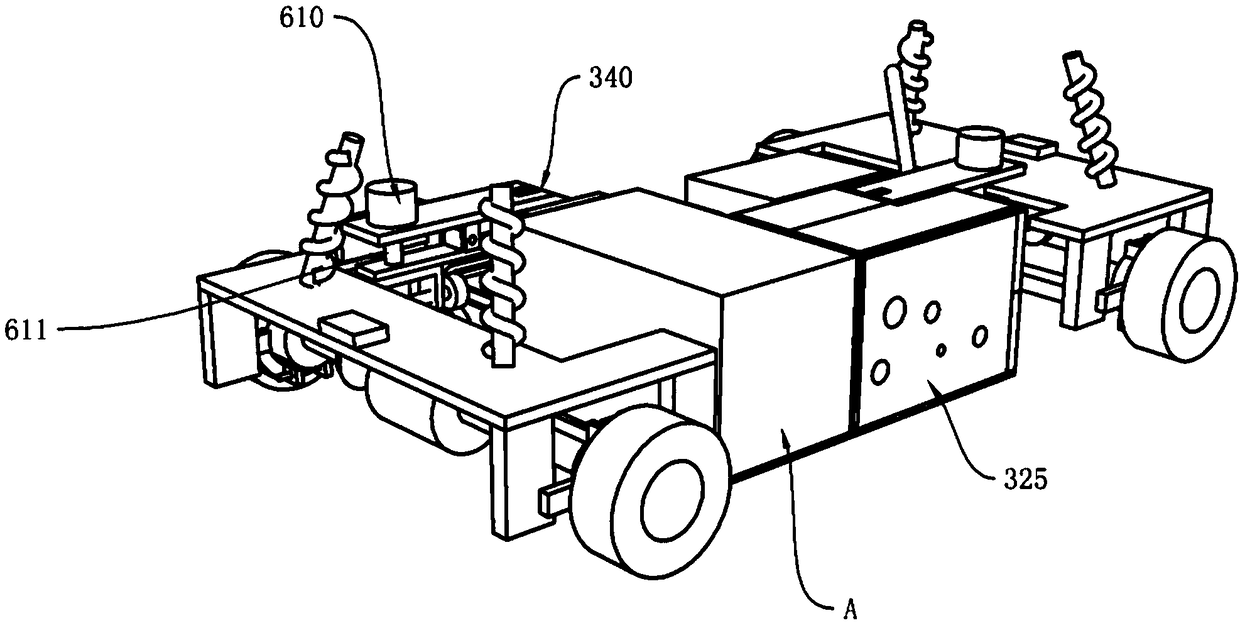

[0071] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

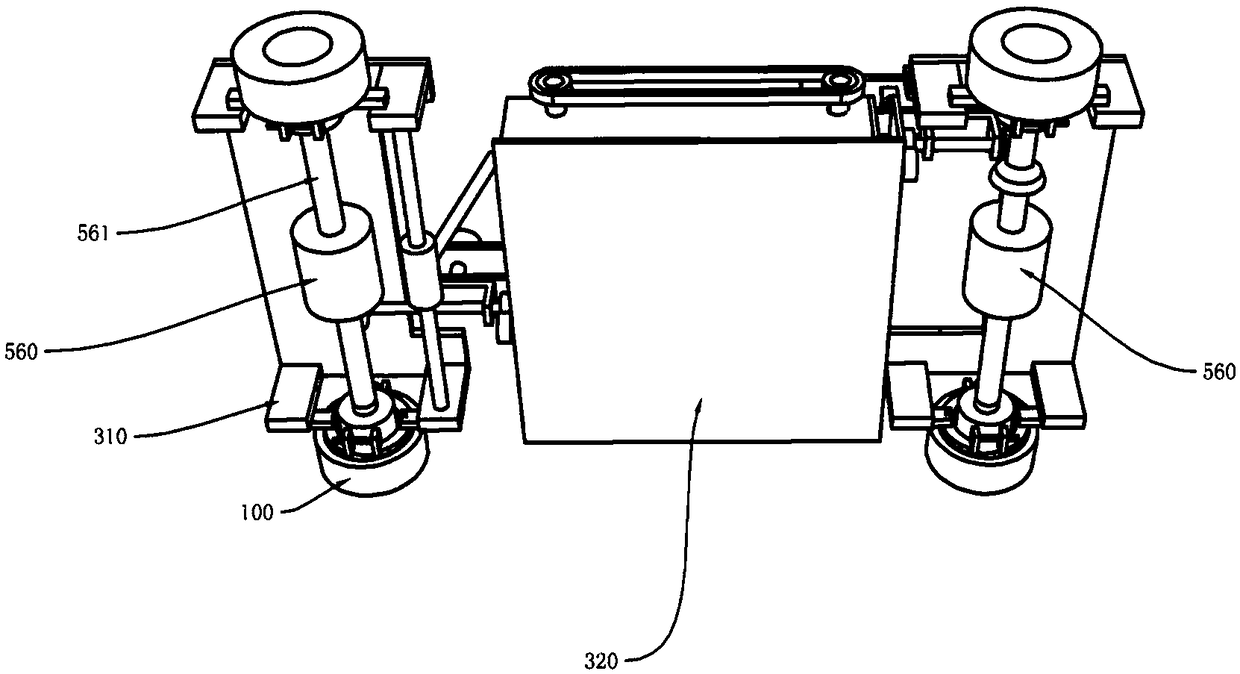

[0072] see Figure 1-Figure 10 , an electric vehicle chassis, including a hub assembly, the hub assembly includes a hub 100, the hub 100 is provided with a brake and the hub is installed on the transmission hub 110, the brake can directly use the existing brake structure and controls;

[0073] The drive hub 110 is assembled and fixed with one end of the drive output shaft 561 of the drive motor 560. When in use, the drive motor 560 can drive the drive output shaft 561 to rotate, thereby driving the wheel hub 100 to rotate;

[0074] The brake is provided with a brake connection plate 130, the brake connection plate 130 is connected and fixed with the chassis connection plate 310, and the chassis connection plate 310 is connected and fixed with the first bottom plate 311;

[0075] The part of the chassis located at the front hub is the front chassis assembly,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com