Simple and convenient disassembling and assembling device of horizontal flange connecting device

A connecting device, horizontal technology, applied in the field of disassembly and assembly devices, can solve the problems of high cost, time-consuming and laborious disassembly and assembly, and inconvenience, and achieve the effects of low cost, high efficiency, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

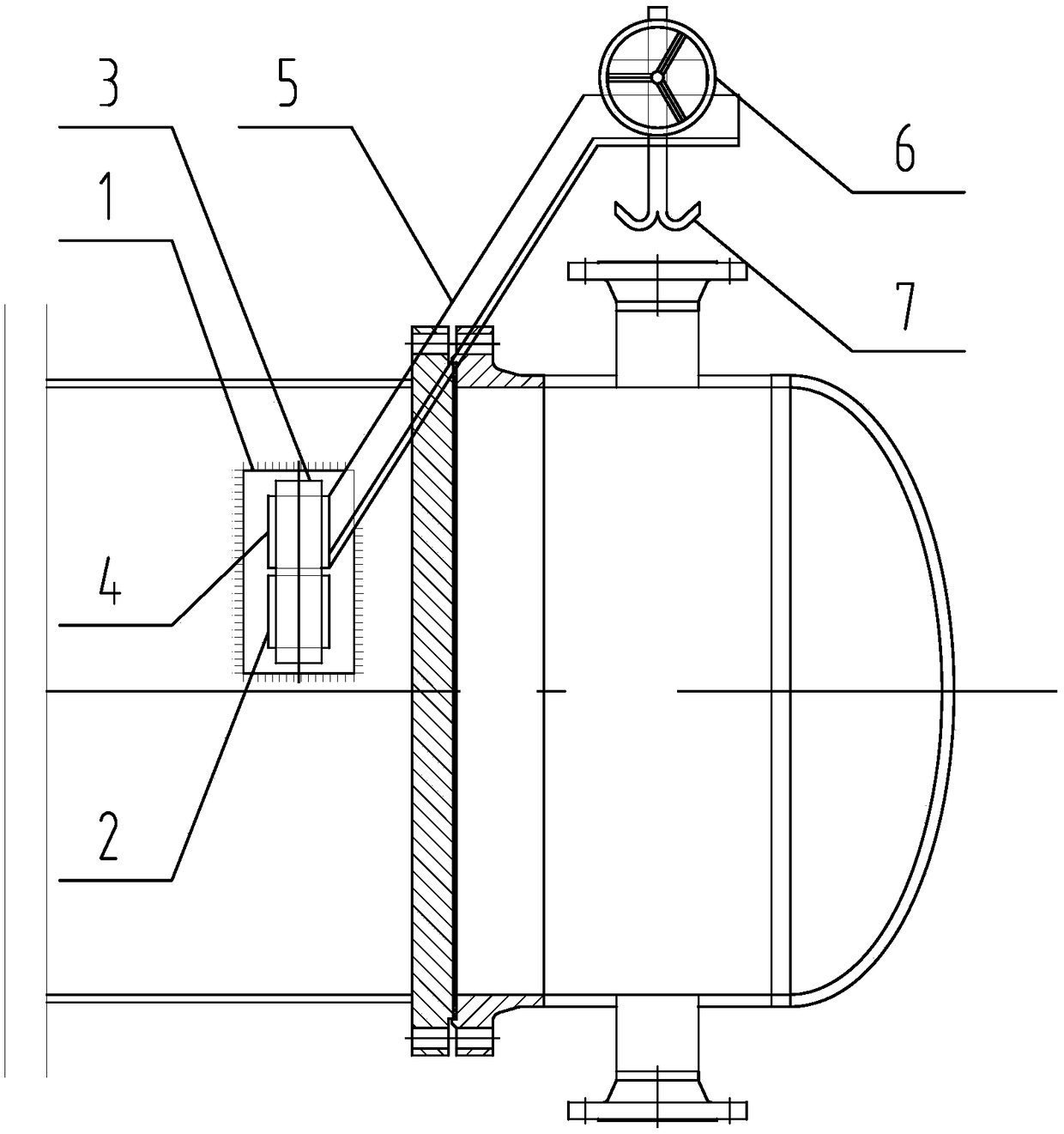

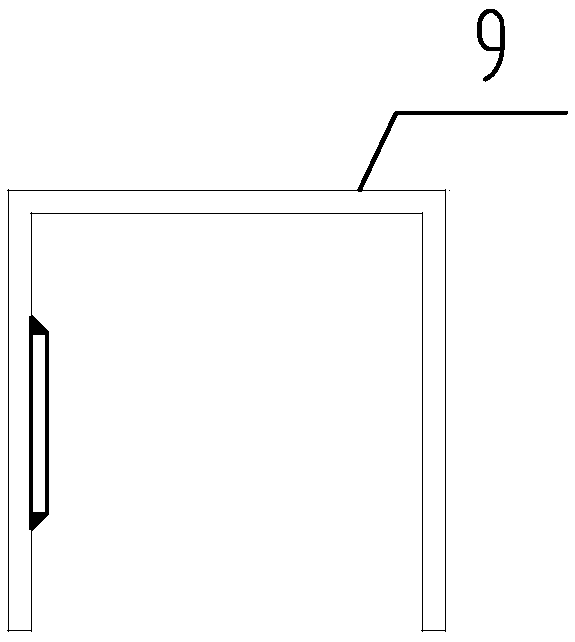

[0019] like figure 1 Shown: The flange connection equipment is a new horizontal heat exchanger, which includes two parts, the shell side and the tube box. One side of the shell side is provided with a connecting plate 1, the bearing seat 2 is directly welded on the connecting plate 1, and the shaft 3 is installed On the bearing seat 2, the shaft sleeve 4 is set on the shaft 3, the boom 5 is set obliquely, the lower end is connected with the shaft sleeve 4, and the upper end is provided with a manual worm gear screw lifter 6 and a hook 7, and the hook 7 is connected to the worm gear wire The lifting screw mandrel of rod lifter 6 is connected.

[0020] The new horizontal heat exchanger of this embodiment is disassembled and then reassembled for on-site inspection and maintenance as follows:

[0021] ①Weld the bearing seat 2 directly to the connecting plate 1 on the side of the shell, connect the hook 7 and the pipe box on the right side of the flange with a wire rope, and turn ...

Embodiment 2

[0025] The flange connection equipment is an old horizontal heat exchanger, and its shell-side cylinder is allowed to be welded. Others are the same as in Embodiment 1.

[0026] The on-site maintenance of this embodiment is completely the same as that of Embodiment 1 when it is first dismantled and then reassembled.

Embodiment 3

[0028] The flange connection equipment is an old horizontal heat exchanger, and its shell-side cylinder is not allowed to be welded. Others are the same as in Embodiment 1.

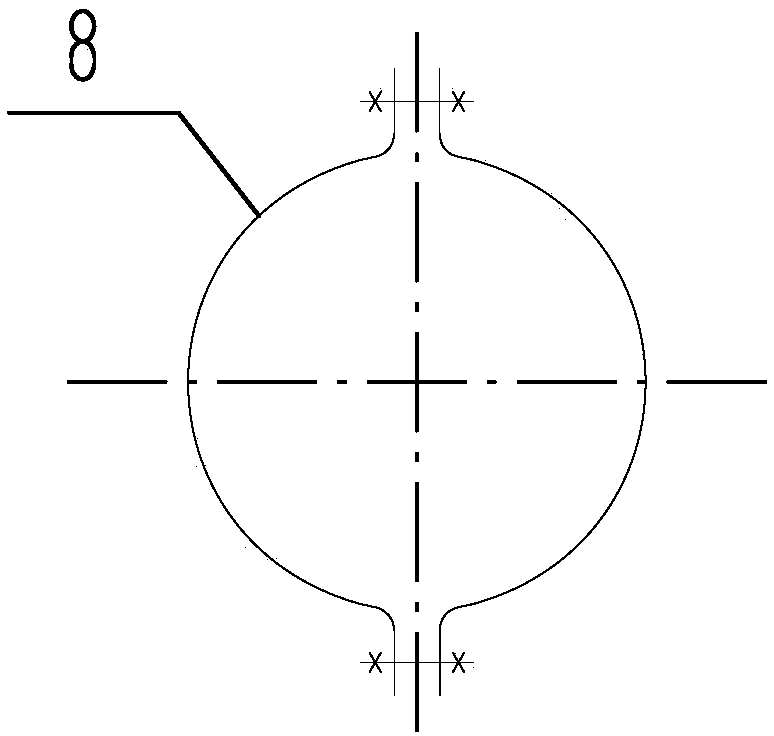

[0029] In this embodiment, when on-site maintenance is first dismantled and then reassembled, if figure 2 As shown, a clamp 8 is prefabricated first and the clamp 8 is fastened on the shell side cylinder, and then the connecting plate 1 is welded to the clamp, and the rest is completely the same as that of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com