Anti-loose cable arranging device and unattended winch

A technology of anti-loosening and cable discharge, which is applied in the direction of hoisting device and clockwork mechanism, etc., can solve the problems of winch not working normally, disorder, stuck between inner cables, etc., to improve the effect of pulling and cable discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

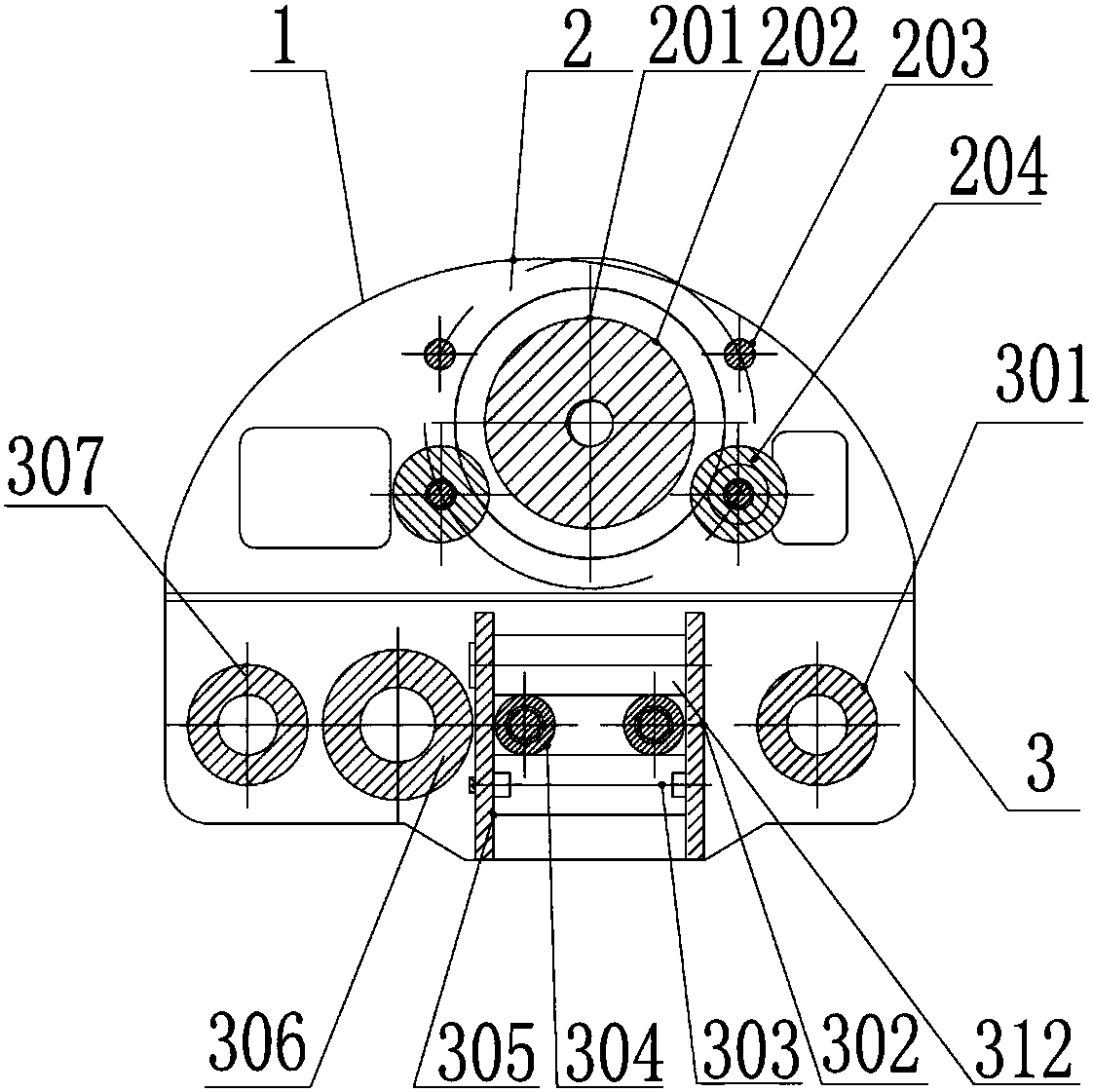

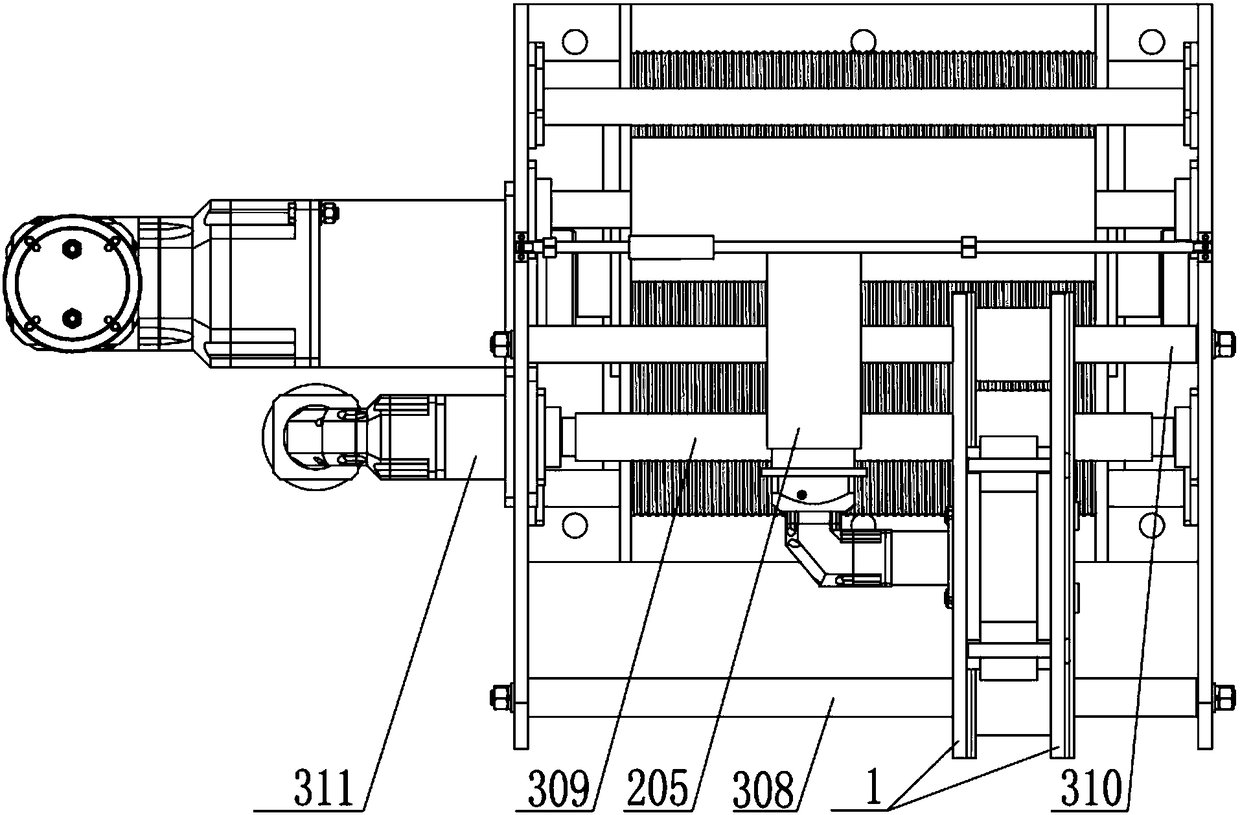

[0031] Such as figure 1 and figure 2 As shown, the present invention comprises a kind of anti-loose cable discharge device, and described anti-loose cable discharge device comprises support frame 1, anti-loose part 2 and cable discharge part 3, and support frame 1 is two oppositely arranged support frames, anti-loosening The loose part 2 and the cable discharge part 3 are arranged between the two supporting frames, and the anti-loose part 3 is arranged above the cable discharge part 3 .

[0032] The anti-loosening part 2 includes an anti-loosening motor 205, an anti-loosening roller 201 and a pressure roller I204. The anti-loosening roller 201 is located between the two supporting frames 1, and the anti-loosening roller 201 is fixed on the central axis 202 of the anti-loosening roller. The central axis of the anti-loosening roller The two ends of 202 are respectively hinged with two supporting frames. The output shaft of the anti-loosening motor 205 is fixedly connected wit...

Embodiment 2

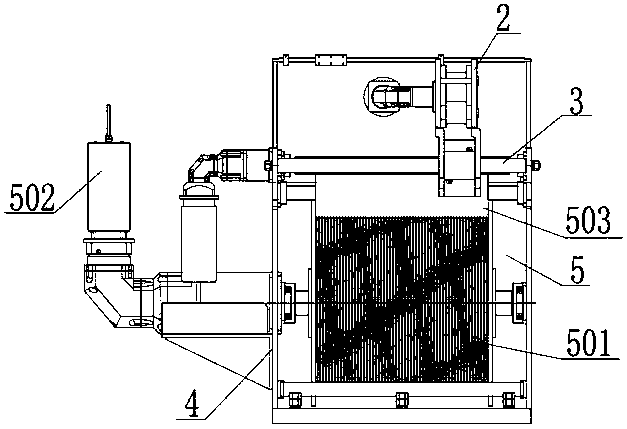

[0037] The present invention also includes an unattended winch, which includes a casing 4, a receiving part 5 and the anti-loose cable discharge device described in Embodiment 1, such as image 3 As shown, the anti-loose cable discharge device and the receiving part 5 are all arranged on the casing 4, wherein the cable discharge screw in the anti-loose cable discharge device and both ends of the cable discharge rod are connected to the casing 4, wherein the cable discharge wire The bar is hinged with the casing 4, and the cable discharge screw is fixedly connected with the casing 4. The cable discharge part 5 is located below the cable release device, and includes a winch 501, a cable take-up motor 502 and a pressure roller II 503, wherein the two ends of the winch 501 are respectively hinged with the casing 4, and the winch 501 is hinged with the output shaft of the cable take-up motor 502, The outer surface of the winch 501 is provided with a spiral groove 509, which is conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com