A polyurea elastomer that completely replaces polyether with polysiloxane and its preparation method

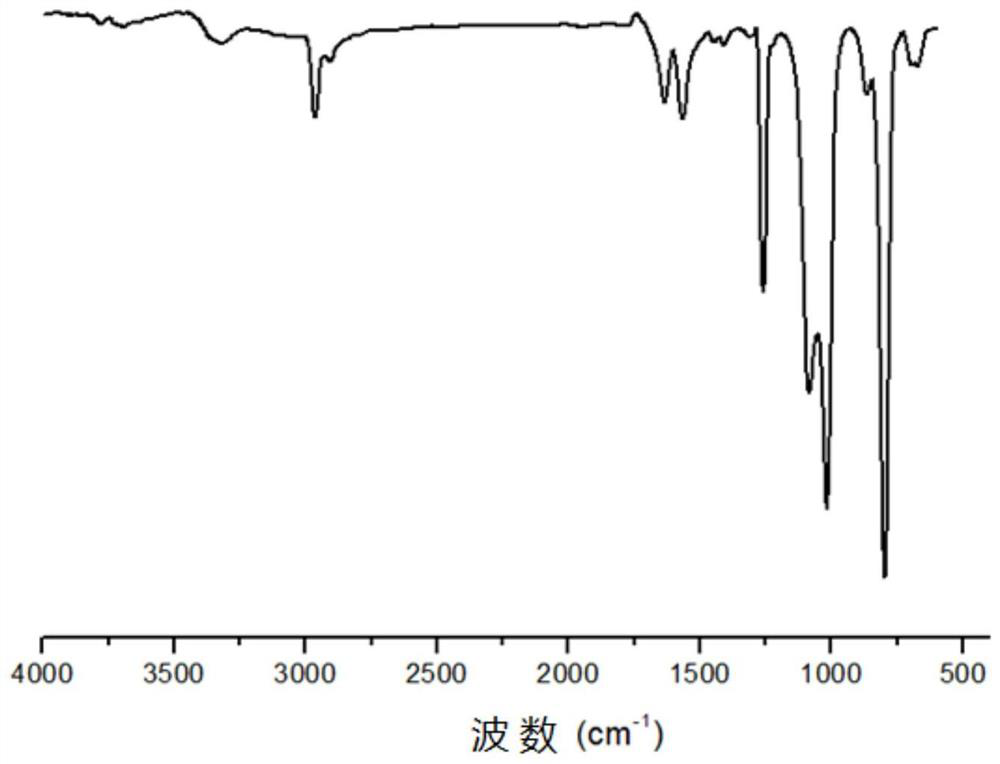

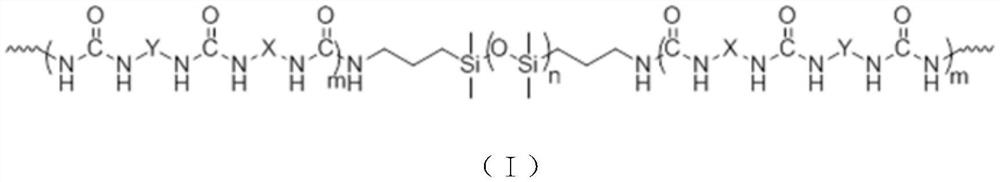

A technology of polyurea elastomer and polysiloxane, which is applied in the field of synthesis of organosilicon polymer materials, can solve the problems of low reactivity, high temperature required for reaction, long reaction time, etc., and achieve simple reaction process, less Small microscopic phase separation, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

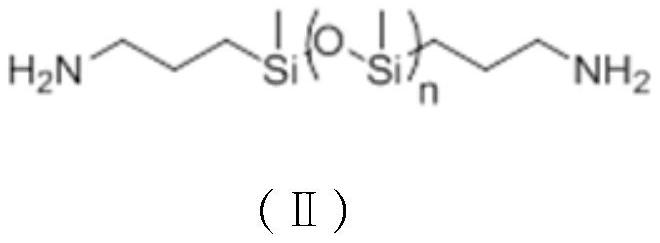

[0048] A kind of preparation method of the polyurea elastomer that completely replaces polyether with polysiloxane, comprises steps as follows:

[0049] In a four-necked flask equipped with a constant pressure dropping funnel, a drying tube, a mechanical stirrer, and a nitrogen gas feed device, add 30 g of dicyclohexylmethane diisocyanate, and mix with xylene and isopropanol (volume ratio: 6:1) The mixed solvent is completely dissolved, and under strong stirring, 70g of aminopropyl-terminated polydimethylsiloxane C with a molecular weight of 4000 is completely dissolved and then added dropwise to the above solution through the dropping funnel, and reacted at 40°C 30min, prepolymer D was prepared, and finally 20g of 2-methyl-1,5-pentanediamine was dissolved in the mixed solution, added dropwise into the reactor through the dropping funnel, reacted at 5°C for 10min, and poured the product into In the mold, the solvent is volatilized at room temperature to obtain an elastomer.

...

Embodiment 2

[0055] A kind of preparation method of the polyurea elastomer that completely replaces polyether with polysiloxane, comprises steps as follows:

[0056] In a four-necked flask equipped with a constant pressure dropping funnel, a drying tube, a mechanical stirrer, and a nitrogen gas feed device, add 20 g of diphenylmethane diisocyanate, and use tetrahydrofuran and dichloromethane (volume ratio: 8:1) The mixed solvent is completely dissolved, and under strong stirring, 60 g of aminopropyl-terminated polydimethylsiloxane C with a molecular weight of 2000 is completely dissolved and then added dropwise to the above solution through the dropping funnel, and reacted at 30°C for 10 minutes , to prepare prepolymer D, and finally dissolve 20g of hexamethylenediamine in the mixed solution, add it dropwise into the reactor through the dropping funnel, react at 10°C for 15min, pour the product into the mold, and remove the solvent by volatilization at room temperature. Get the elastomer. ...

Embodiment 3

[0061] A kind of preparation method of the polyurea elastomer that completely replaces polyether with polysiloxane, comprises steps as follows:

[0062] In a four-necked flask equipped with a constant pressure dropping funnel, drying tube, mechanical stirring and nitrogen feed device, add 30 g of dicyclohexylmethane diisocyanate, and use dimethyl sulfoxide and n-hexane (volume ratio is 8: 1) The mixed solvent is completely dissolved, and under strong stirring, 70 g of block copolymer A with a molecular weight of 3000 is completely dissolved and then added dropwise to the above solution through a dropping funnel, and reacted at 40°C for 20 minutes to prepare a prepolymer Object D, finally dissolve 20g of 4,4'-methylene bis(2-ethyl 6-methylcyclohexylamine) in the mixed solution, add it dropwise into the reactor through the dropping funnel, and react at 10°C for 20min , Pour the product into a mold, and evaporate the solvent at room temperature to obtain an elastomer.

[0063] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com