Preparation technology of cool silk heterochromatic knitted fabric

A knitted fabric and preparation process technology, applied in the field of textile fabrics, can solve the problems of dry hand, no slippery feeling, no cooling function, etc., and achieve the effects of excellent oil removal, uniform stripe feeling, and good antistatic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0037] A cool-feeling silk tone different-color knitted fabric and its preparation process, comprising the following steps:

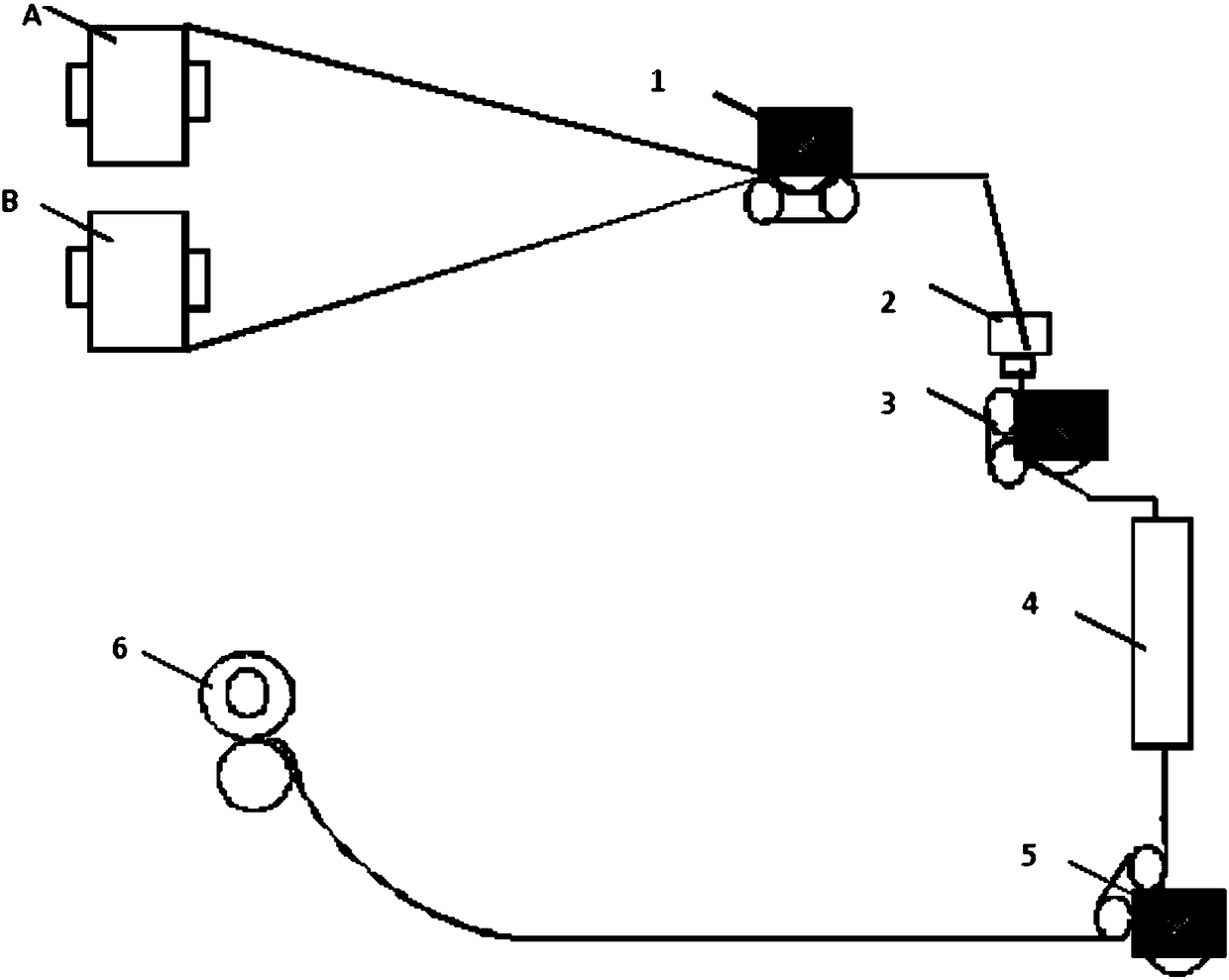

[0038] Step 1. Preparation of raw silk: Polyamide fiber and polyester fiber are combined to form a composite yarn. The specific operation is as follows: the polyamide fiber (A) and polyester fiber (B) are drawn out from the creel respectively, and then the two yarns are The wires enter the first roller (1) together, enter the specific network composite nozzle (2) with the same overfeed rate of 1%, and composite under the action of the air pressure in the nozzle. The hole diameter of the nozzle is 1.4mm, and the air pressure at the nozzle Be: 4kg, pass through yarn guiding tube (4), the 3rd roller (5) together again, final winding molding obtains composite yarn (6) of the present invention; The denier of described composite yarn is: 30D, and shrinkage rate is 4 %, strength: 3.57cN / dtex, elongation: 29.5%; wherein, the speed is 396m / min, the speed of the ...

specific Embodiment 2

[0047] A cool-feeling silk tone different-color knitted fabric and its preparation process, comprising the following steps:

[0048] Step 1. Preparation of raw silk: Polyamide fiber and polyester fiber are combined to form a composite yarn. The specific operation is as follows: the polyamide fiber (A) and polyester fiber (B) are drawn out from the creel respectively, and then the two yarns are The wires enter the first roller (1) together, enter the specific network composite nozzle (2) with the same overfeed rate of 1%, and composite under the action of the air pressure in the nozzle. The hole diameter of the nozzle is 1.4mm, and the air pressure at the nozzle Be: 4kg, pass through yarn guiding tube (4), the 3rd roller (5) together again, final winding molding obtains composite yarn (6) of the present invention; The denier of described composite yarn is: 100D, and shrinkage rate is 8 %, strength: 3.57cN / dtex, elongation: 29.5%; wherein, the speed is 396m / min, the speed of the...

specific Embodiment 3

[0057] A cool-feeling silk tone different-color knitted fabric and its preparation process, comprising the following steps:

[0058] Step 1. Preparation of raw silk: Polyamide fiber and polyester fiber are combined to form a composite yarn. The specific operation is as follows: the polyamide fiber (A) and polyester fiber (B) are drawn out from the creel respectively, and then the two yarns are The wires enter the first roller (1) together, enter the specific network composite nozzle (2) with the same overfeed rate of 1%, and composite under the action of the air pressure in the nozzle. The hole diameter of the nozzle is 1.4mm, and the air pressure at the nozzle Be: 4kg, pass through yarn guiding tube (4), the 3rd roller (5) together again, final winding molding obtains composite yarn (6) of the present invention; The denier of described composite yarn is: 70D, and shrinkage rate is 6 %, strength: 3.57cN / dtex, elongation: 29.5%; wherein, the speed is 396m / min, the speed of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com