A pile centering device and a pile centering process using the pile centering device

A centering device and pile position technology, which is applied in the direction of sheet pile wall, foundation structure engineering, foundation structure test, etc., can solve the problem that the bite length of piles does not meet the design requirements, affects the progress of the project and construction quality, and is not applicable to large Problems such as pile formation in batches, to achieve fast production, avoid re-drilling and repairing piles, and ensure the construction period and project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

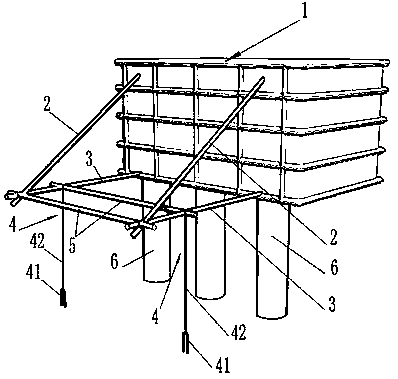

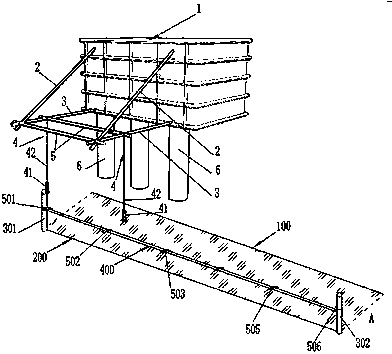

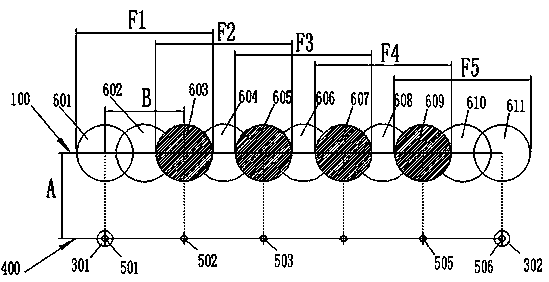

[0033] see Figure 1-5 , a pile position centering device, including two diagonal struts 2 arranged at the front end of a support frame 1 of a three-axis pile driver, two outwardly moving positioning rods 3 and two connecting components 4; the two outwardly moving positioning rods 3 are arranged horizontally and mutually Parallel, the rear ends of the two outwardly moving positioning rods 3 are respectively fixed on the lower part of the front end of the support frame 1; the centerlines of the two outwardly moving positioning rods 3 are respectively perpendicular to the centerlines of the drilling rods 6 on both sides of the three-axis drilling rod, And the centerlines of the outward positioning rod 3 and the drilling rod 6 on the same side are located in the same vertical plane; the front ends of the two outward positioning rods 3 are fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com