Middle header applicable to low-load flexible operation of supercritical boiler

A technology for supercritical boilers and intermediate headers, which is applied in boiler drums/box headers, components of steam boilers, steam boilers, etc., and can solve uneven heat load distribution, water-cooled wall safety issues, and mass flow rate Reduce and other problems, to achieve the effect of reducing the minimum stable operating load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

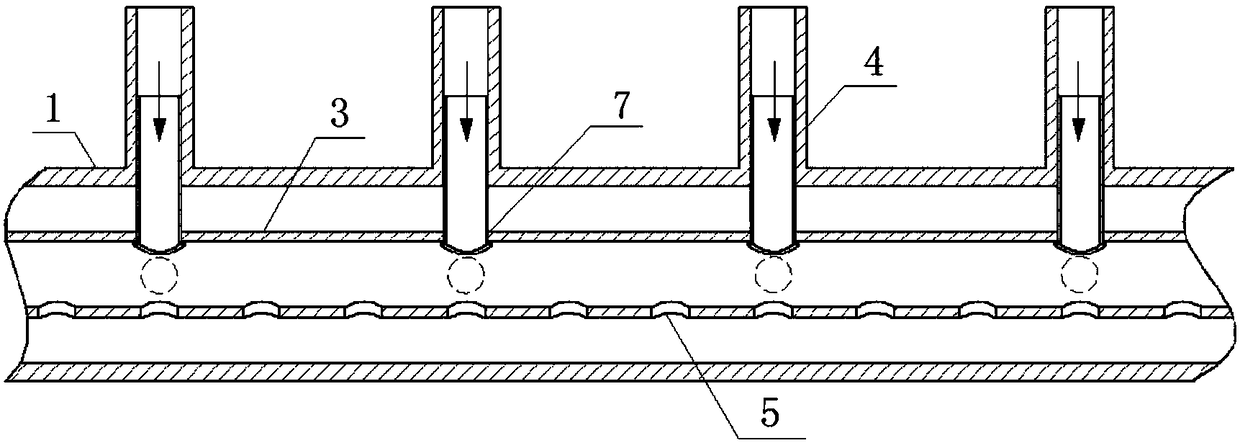

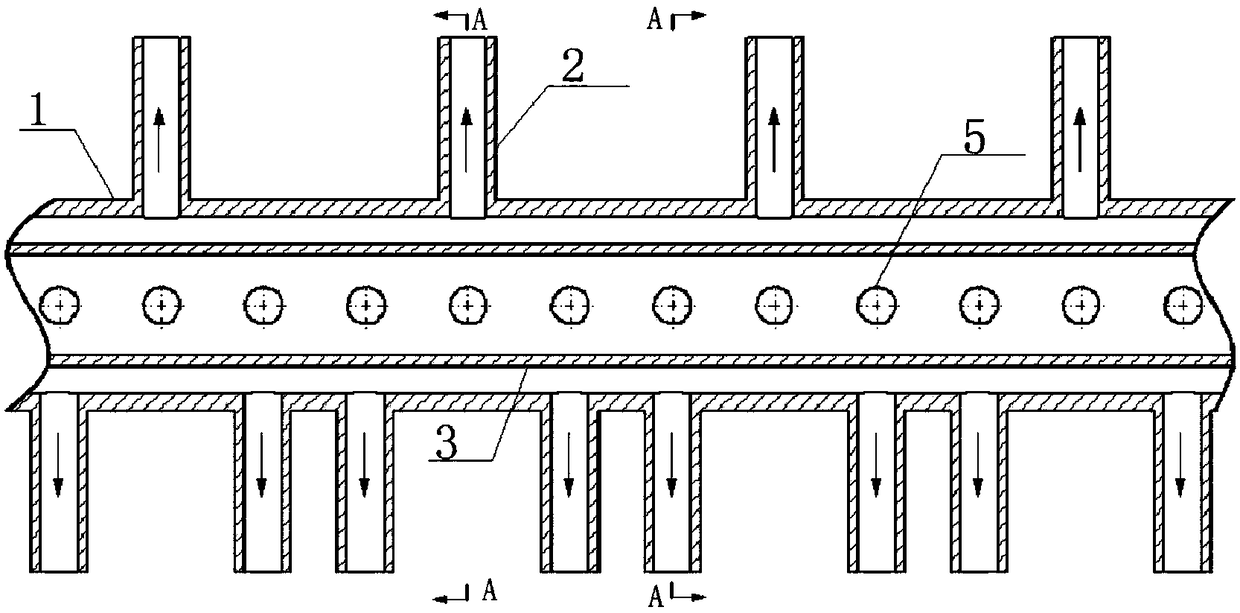

[0021] Different from the geometric structure of the intermediate header of conventional supercritical boilers, the present invention adopts the design method of adding coaxial flute tubes inside the intermediate header, which will be described below in conjunction with the accompanying drawings.

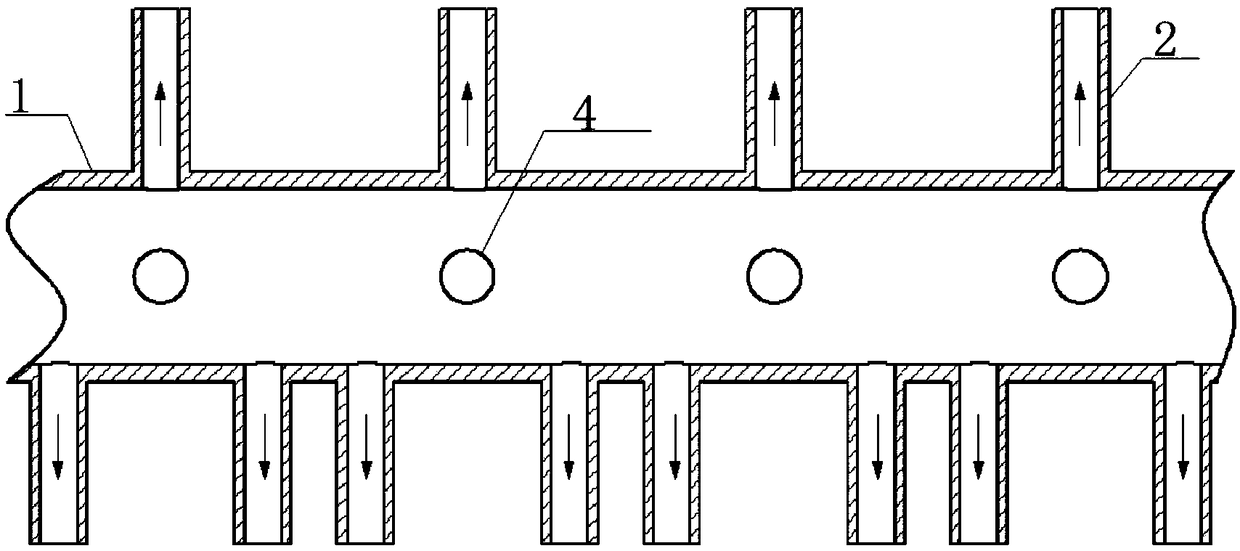

[0022] Such as figure 1 As shown, the vertically downward and radially introduced water-cooled wall intermediate headers currently used in power plants mainly include: header main body 1 (φ219×60mm, length range 10m~12m), introduction pipe 4 (φ38×6.5mm) and branch pipes 2 (φ31.8×5.5mm); the header main body 1 is a thick-walled tubular device arranged horizontally, and the introduction pipes 4 are installed vertically above the pipe wall of the header main body 1 at equal intervals, and the branch pipes 2 Installed horizontally on both sides of the pipe wall of the main body 1 of the header, and arranged in a zigzag pattern; the branch pipes 2 on one side are each in a group, corresp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap