Atomizer and electronic cigarette

An atomizer and electronic cigarette technology, applied in tobacco, smoker's products, applications, etc., can solve problems such as poor conduction of leaking smoke and liquid, and achieve the effect of improving user experience, convenient operation, and avoiding dry burning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

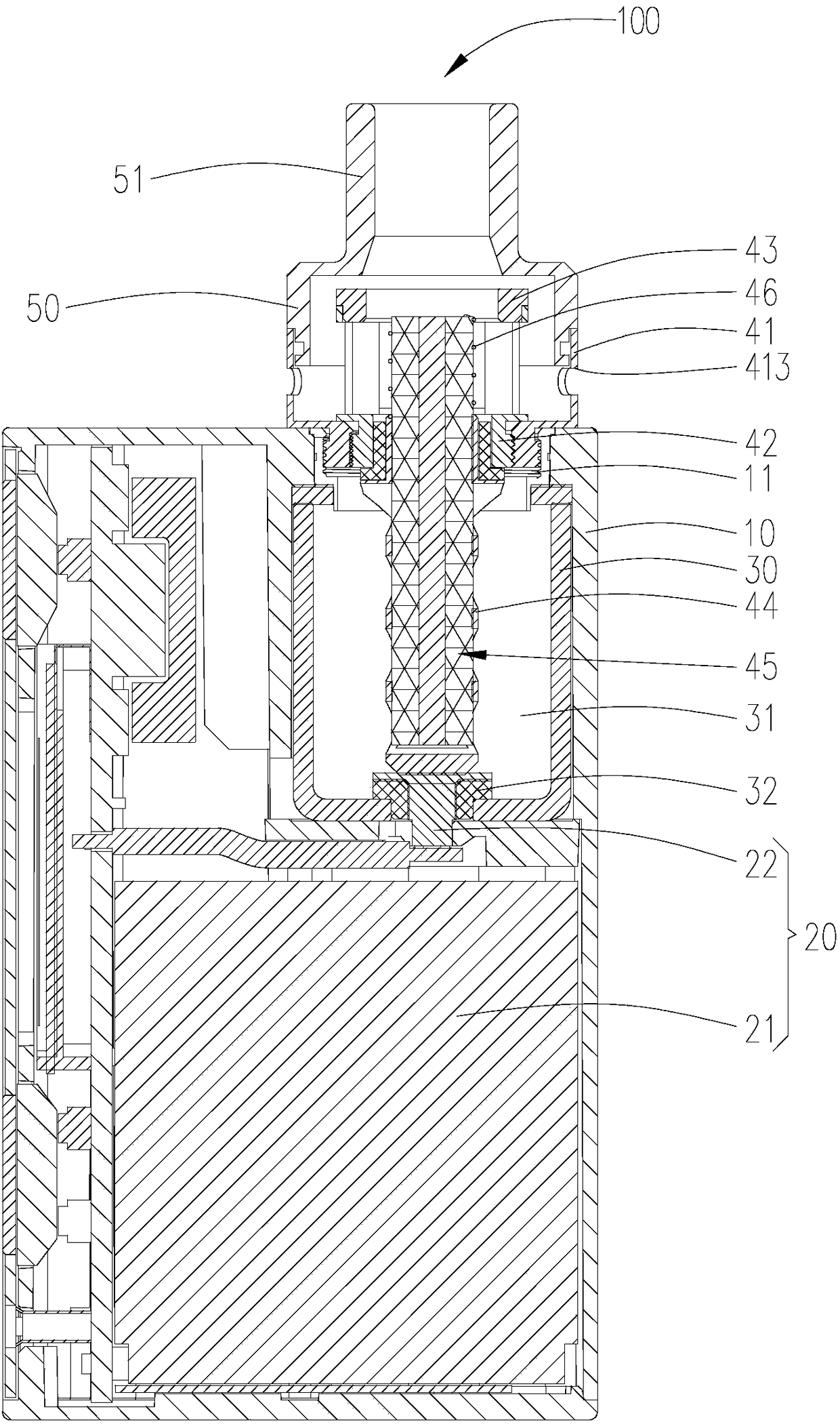

[0067] see Figure 8 The difference between the electronic cigarette (shown in the figure) provided in the second embodiment and the electronic cigarette 100 in the first embodiment is that only the first liquid absorbing member 451 can be provided in the accommodation cavity of the pole 44, and the atomization The cavity 422 includes both the first liquid absorbing part 451 and the second liquid absorbing part 452, that is, a part of the liquid guiding part 45 is accommodated in the accommodating cavity, and the other part of the liquid guiding part 45 is contained in the mist In the atomization chamber 422, the first liquid absorption part 451 in the accommodation chamber absorbs the e-liquid and conducts it upwards. When the e-liquid reaches the atomization chamber 422, it passes through the second liquid absorption part 451 attached to the first liquid absorption part. Part 452 reaches the heating part 46 and is heated and atomized. In the second embodiment, since the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com