Paper supply device, automatic paper transferring device and image formation device

A paper feeding device and paper technology, which are applied in the directions of object supply, transportation and packaging, and object separation, etc., can solve the problems of bending and folds, paper jams, large angles, etc., and achieve the effects of suppressing deformation, suppressing paper jams, and reducing paper jams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

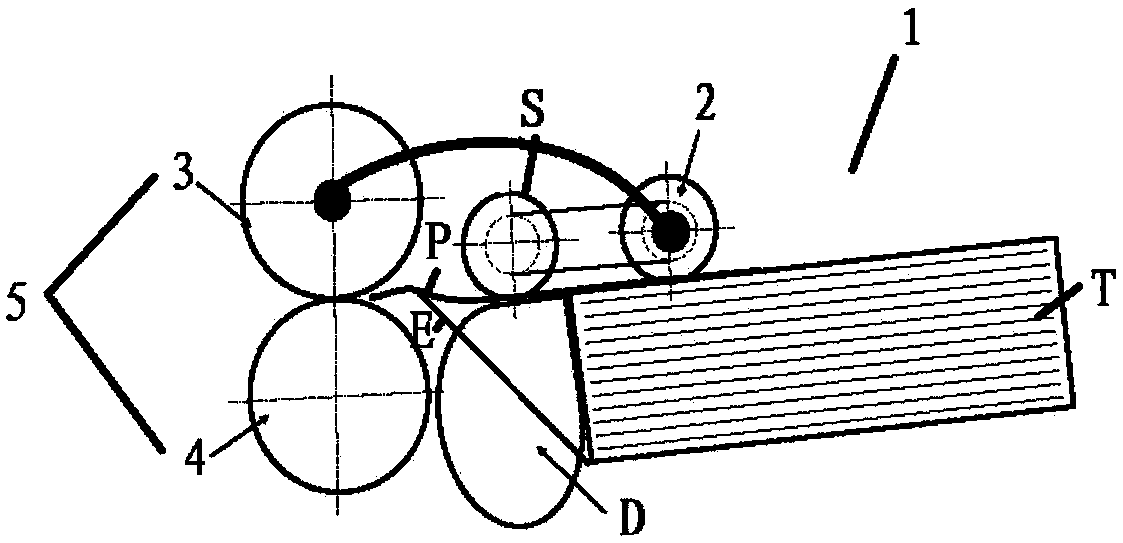

[0035] Fig. 1 (A), Fig. 1 (B), Fig. 1 (C) are the schematic diagrams of the paper feeding device of Embodiment 1 of the present invention, wherein, Fig. 1 (A) shows the state when paper is fully loaded, and Fig. 1 (B ) shows the state when the paper is half-loaded, and FIG. 1(C) shows the state when the paper is empty.

[0036]As shown in FIG. 1(A), the paper feeding device 1 according to Embodiment 1 of the present invention is mainly composed of the following parts: a paper feeding tray F on which a paper stack T is placed; a paper pickup roller 2, It extracts the paper P from the paper stack T and conveys it to the paper feed roller pair 5; The nip between the separation rollers 4, through which paper is fed one by one to the image forming device; Between the rollers 4), when the paper P is conveyed, the paper is supported from the lower side of the paper P, and the position is changed according to the height of the paper stack T, that is, the decrease or increase of paper...

Embodiment approach 2

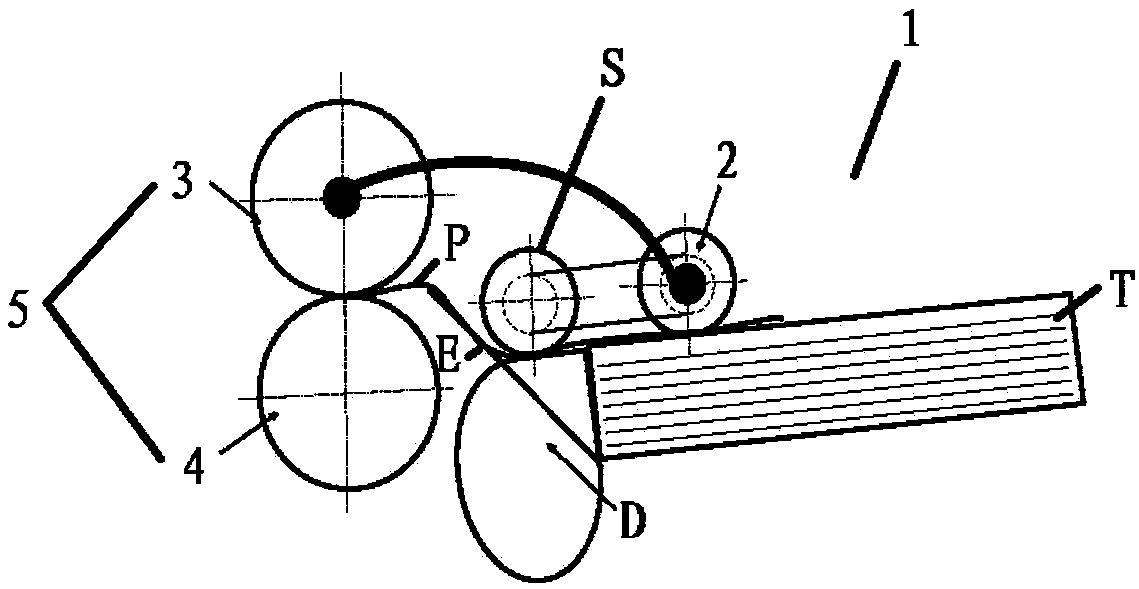

[0056] Fig. 3 (A), Fig. 3 (B) and Fig. 3 (C) are the schematic diagrams of the paper feeding device of embodiment 2 of the present invention, wherein, Fig. 3 (A) shows the state when paper is fully loaded, Fig. 3 (B ) shows the state when the paper is half-loaded, and FIG. 3(C) shows the state when the paper is empty.

[0057] In this embodiment, only the auxiliary mechanism is different from Embodiment 1, and other configurations are the same as Embodiment 1. Here, the same reference numerals as in Embodiment 1 are given to the same parts as in Embodiment 1, and description thereof will be omitted.

[0058] Such as Figure 3(A)-Figure 3(C) As shown, the auxiliary mechanism in Embodiment 2 is the belt S1. The belt S1 wraps around the pick-up roller 2 and the linkage roller 6, and has a certain width. During the paper conveying process, the pick-up roller 2 rotates, and the belt S1 rotates accordingly, and the conveying force is generated by the contact between the belt S1 an...

Embodiment approach 3

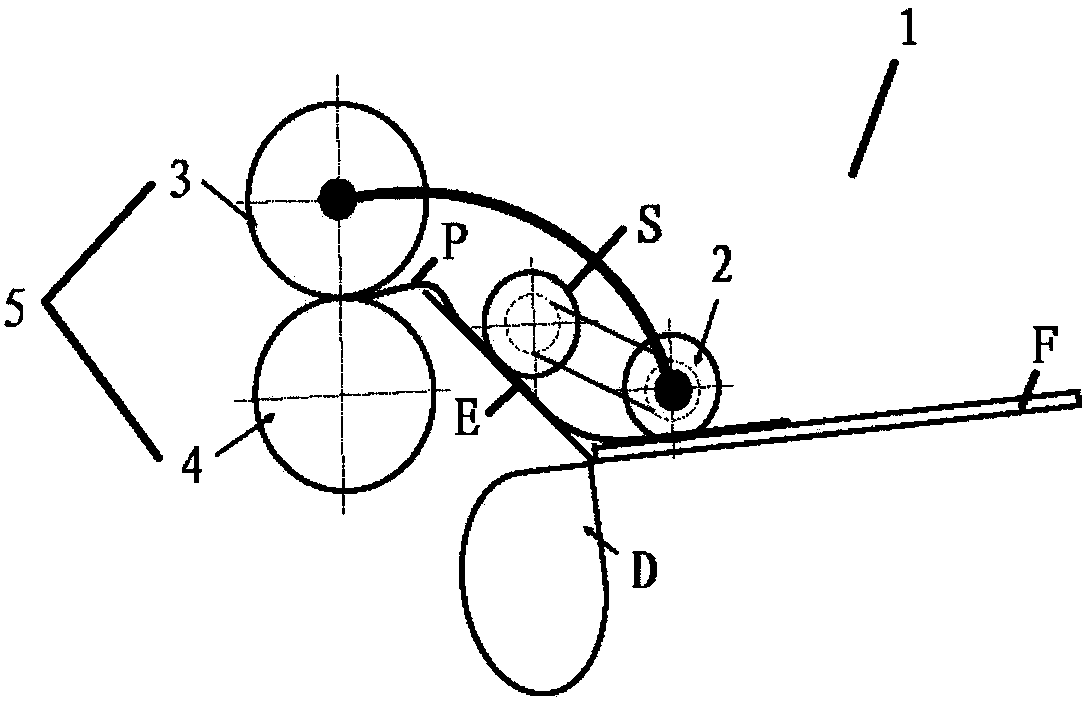

[0063] 4(A), FIG. 4(B) and FIG. 4(C) are schematic diagrams of the paper feeding device according to Embodiment 3 of the present invention, wherein FIG. 4(A) shows the state when the paper is fully loaded, and FIG. 4(B ) shows the state when the paper is half-loaded, and FIG. 4(C) shows the state when the paper is empty.

[0064] In this embodiment, only the auxiliary mechanism is different from Embodiment 1, and other configurations are the same as Embodiment 1. Here, the same reference numerals as in Embodiment 1 are given to the same parts as in Embodiment 1, and description thereof will be omitted.

[0065] Such as Figure 4(A)-Figure 4(C) As shown, the auxiliary mechanism in Embodiment 3 is paddle S2. This paddle S2 is constituted by a cylindrical member 7 as a main body and a plurality of paddle pieces 8 protruding from the surface of the cylindrical member 7 in a direction tangential to the outer circumference of the cylindrical member 7 . The central shaft portion o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com