A method for passivating tkx-50 using nitroguanidine as a desensitizing agent

A technology of TKX-50 and nitroguanidine, applied in the direction of non-explosive desensitizer/passivator, non-explosive/non-thermal agent components, explosives, etc., can solve immature coating process, explosive performance and mechanical properties Ideal, low mechanical sensitivity and other issues, to achieve the effect of improving surface morphology, safe and reliable operation, and simple preparation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

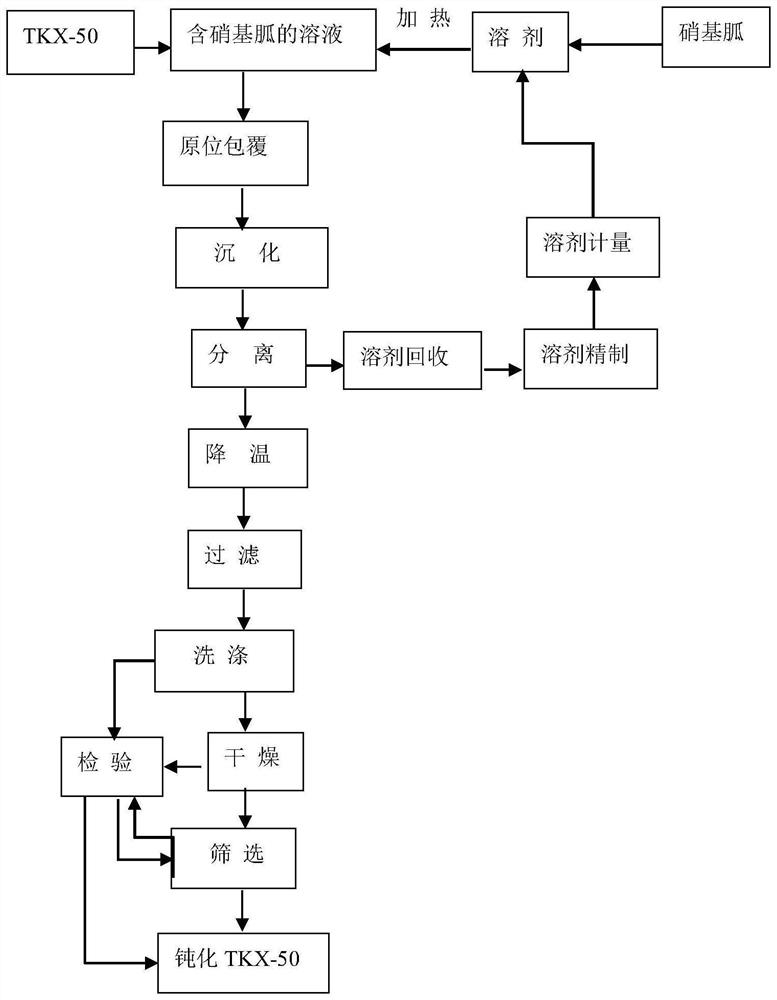

Method used

Image

Examples

Embodiment 1

[0020] A method of passivating TKX-50 using nitroguanidine as a desensitizing agent: at 70°C, with a stirring speed of 300r / min, add 5g of nitroguanidine to 300g of distilled water and stir for 30min to form a uniform mass fraction of 1.64% nitroguanidine solution; keep the temperature at 70°C, add 95g TKX-50 to the nitroguanidine solution obtained above, and stir to make it evenly suspended under the stirring condition of rotating speed 200r / min; Under the stirring condition of 90r / min, the temperature of the obtained suspension was raised to 75°C, and after 30min of heat preservation, the temperature was rapidly cooled to 60°C within 2 minutes; Continue to slowly cool down the above suspension to 10°C, and let it stand for 30 minutes until the crystals are completely precipitated from the solution; filter, wash, and dry at a vacuum of 0.06MPa and a temperature of 30°C for 4 hours; TKX after nitroguanidine insensitivity is obtained -50.

[0021] Obtain the TKX-50 white powde...

Embodiment 2

[0023] A method of passivating TKX-50 using nitroguanidine as a desensitizing agent. At 60°C with a stirring speed of 225r / min, add 4g of nitroguanidine to 250g of ethanol and stir for 30min to form a uniform mass fraction of 1.57 % nitroguanidine solution; keep the temperature at 65°C, then add 96g TKX-50 to the nitroguanidine solution obtained above, and stir to make it evenly suspended under the stirring condition of rotating speed 225r / min; Under the stirring condition of 80r / min, raise the temperature of the obtained suspension to 80°C, keep the temperature for 25min, then rapidly cool down to 55°C within 4 minutes; speed, continue to slowly cool the above-mentioned suspension to 15°C, and let it stand for 35min until the crystals are completely precipitated from the solution; filter, wash, and dry at a vacuum of 0.04MPa and a temperature of 20°C for 6h; obtain nitroguanidine insensitive After the TKX-50.

[0024] Obtain the TKX-50 white powder product 99.4g after the ni...

Embodiment 3

[0026] A method of passivating TKX-50 using nitroguanidine as a desensitizing agent. At 65°C with a stirring speed of 200r / min, add 6g of nitroguanidine to 240g of distilled water and stir for 20min to form a uniform mass fraction of 2.44 % nitroguanidine solution; keep the temperature at 65°C, then add 94g TKX-50 to the nitroguanidine solution obtained above, and stir to make it evenly suspended under the stirring condition of rotating speed 250r / min; Under the stirring condition of 90r / min, raise the temperature of the obtained suspension to 85°C, keep the temperature for 20min, then rapidly cool down to 65°C within 2 minutes; Speed, continue to slowly cool the above suspension to 20°C, and let it stand for 25min until the crystals are completely precipitated from the solution; filter, wash, and dry at a vacuum of 0.04MPa and a temperature of 15°C for 10h; obtain nitroguanidine insensitivity After the TKX-50.

[0027] Obtain 99.3g of TKX-50 white powder product after nitrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com