Selectable one-way clutch

A one-way clutch and selector plate technology, applied in one-way clutches, clutches, vehicle sub-unit functions, etc., can solve problems such as shortening the life of the strut 52, and achieve the effect of suppressing yaw moment and translation force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

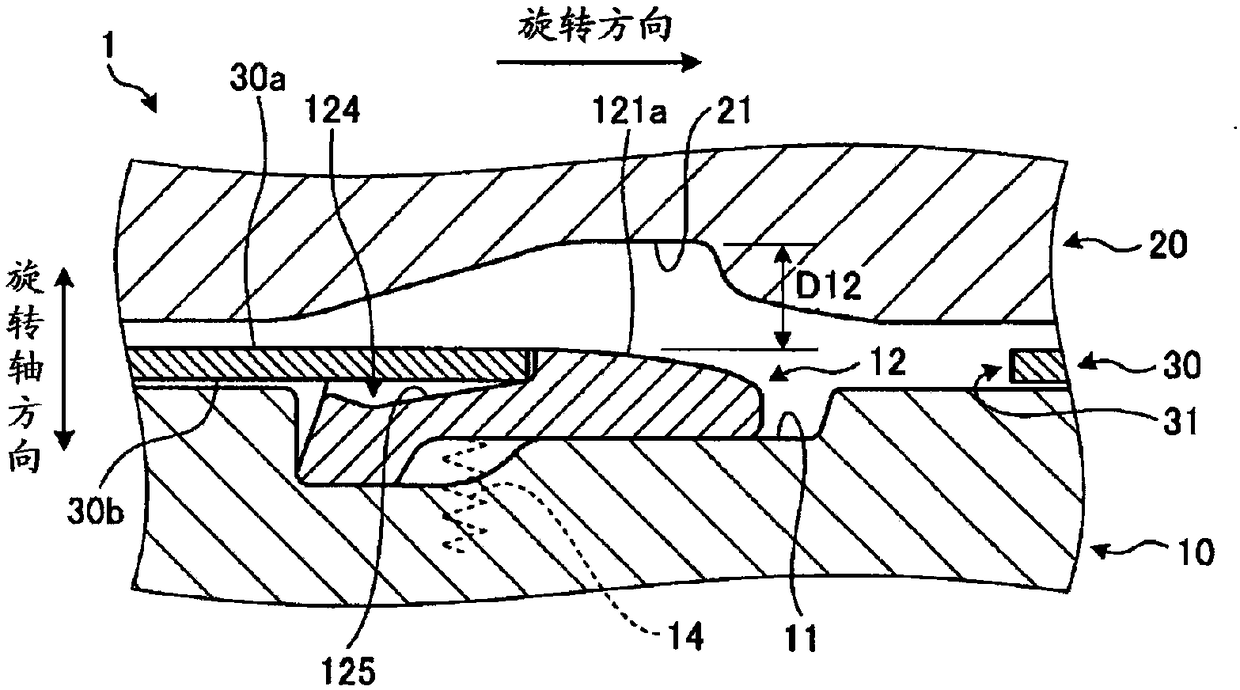

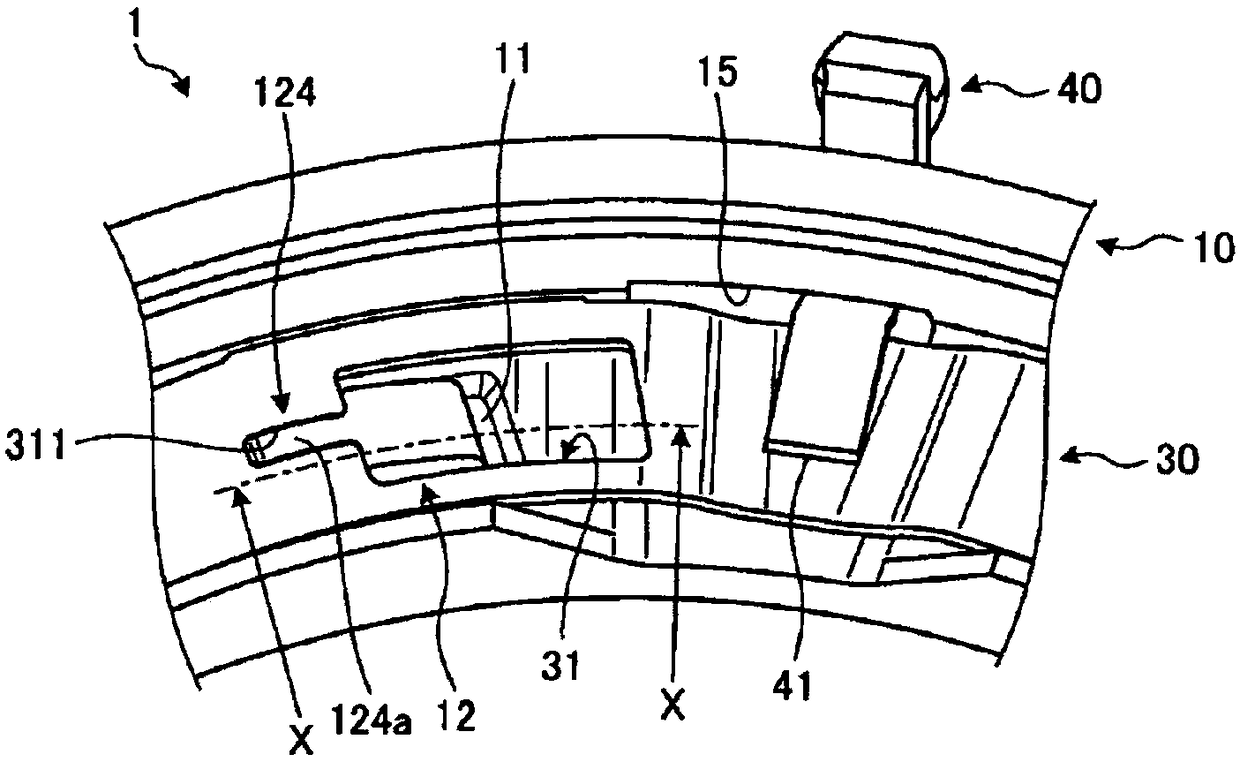

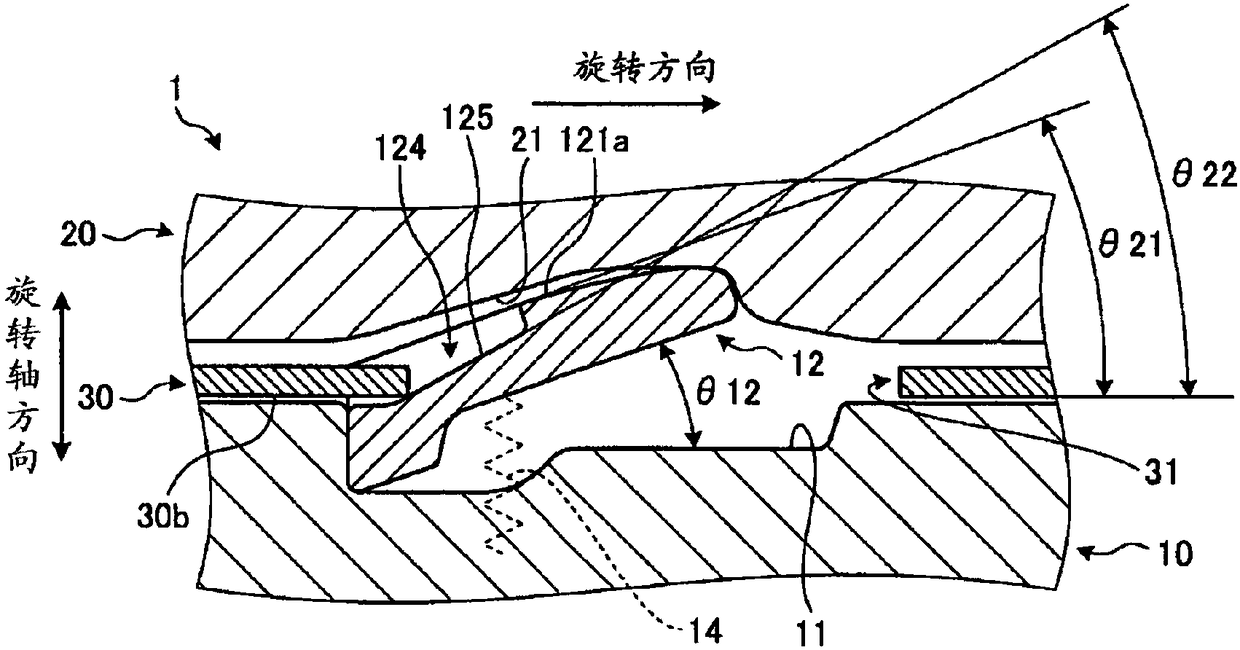

[0070] The SOWC1 of the first embodiment is installed in, for example, a transmission in a hybrid vehicle, such as Figure 1A as well as Figure 1B As shown, there is a pocket plate 10 , a notch plate 20 , an option plate 30 and an arm 40 . It should be noted, Figure 1A is expressed in Figure 1B Shown X-X direction (inner ear portion 122 of pillar (engaging piece) 12 (referring to image 3 ) position) is a cross-sectional view of the state after cutting SOWC1, Figure 1B It is a perspective view which shows the state which removed the notch plate 20 from SOWC1. in addition, Figure 1A The shown "rotational direction" indicates the direction in which the notched plate 20 rotates when overrunning (overrunning direction, non-engagement direction of SOWC1).

[0071] The pocket plate 10 is formed in a cylindrical shape. On one side of the bag plate 10, that is, on the surface facing the notch plate 20, a plurality of pockets (accommodating recesses) 11 that are recessed in...

no. 2 approach

[0108] refer to Figure 8 as well as Figure 9 , the SOWC of the second embodiment will be described. The structure of the SOWC of this embodiment has Figure 8 shown in strut 12A and Figure 9 Except for the selection plate 30A shown, it is the same as the first embodiment.

[0109] The strut 12A extends the slope portion 125 in the strut 12 of the first embodiment to the end of the main body portion 121 . Such as Figure 8 As shown, the strut 12A has a main body portion 121A, an inner ear portion 122 and an outer ear portion 123 . A protruding portion 124A is provided on the upper surface 121a of the main body portion 121A along the circumferential direction of the SOWC. In addition, a pair of slope parts 125A are provided on both sides of the side surface 124b of the protruding part 124A.

[0110] The protruding portion 124A is formed at the center in the width direction of the upper surface 121 a of the main body portion 121A. In addition, the protruding portion 12...

no. 3 approach

[0116] refer to Figure 10 as well as Figure 11 The SOWC1B of the third embodiment will be described. The structure of SOWC1B of this embodiment has Figure 10 Except for the illustrated support 12B, it is the same as the second embodiment.

[0117] In the support column 12B, a part of the slope portion 125A in the support column 12A of the second embodiment is formed into a planar shape. Such as Figure 10 As shown, the strut 12B has a main body portion 121B, an inner ear portion 122 and an outer ear portion 123 . A protruding portion 124B is provided on the upper surface 121a of the main body portion 121B along the circumferential direction of the SOWC1B. In addition, a pair of slope parts 125B are provided on both sides of the side surface 124b of the protruding part 124B. Further, at the position of the top of the slope portion 125B, that is, between the slope portion 125B and the upper surface 121 a of the main body portion 121B, a planar contact portion 126B is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com