Shifting equipment for motor vehicles and motor vehicle transmissions

A technology for motor vehicles and equipment, applied in mechanical equipment, mechanical drive clutches, non-mechanical drive clutches, etc., can solve the problems of unfavorable transmission efficiency, impact, high drag torque, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

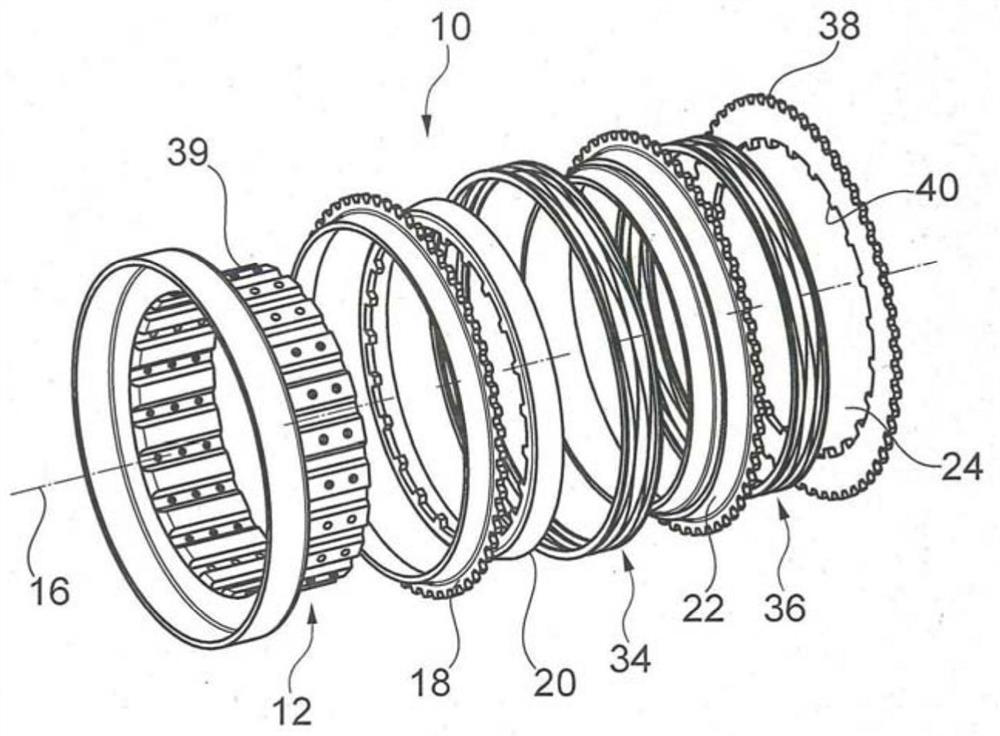

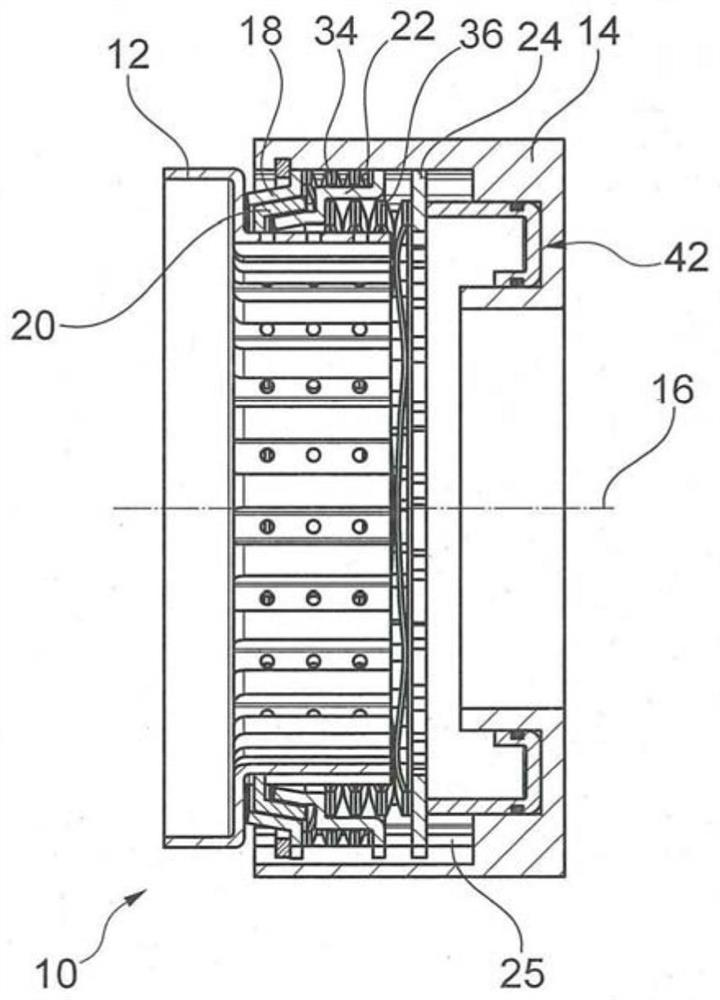

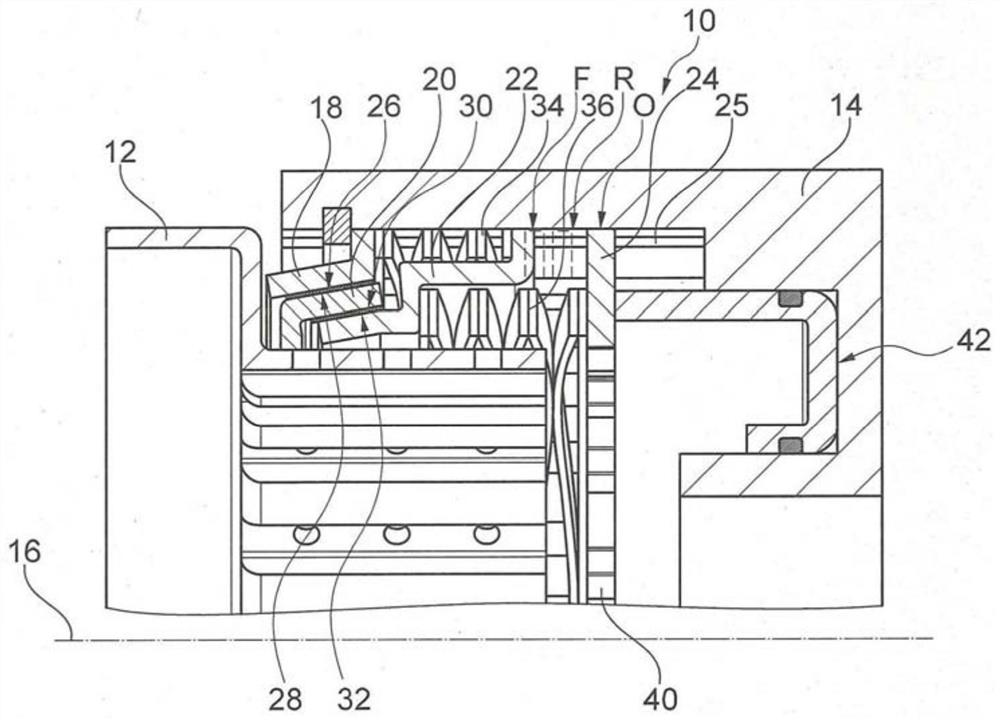

[0066] exist Figures 1 to 3 A shifting device 10 according to a first embodiment is shown in , which comprises a first coupling component 12 and a second coupling component 14 .

[0067] Here, in the embodiment shown, the two coupling components 12 , 14 are shafts or shaft sections that are rotatable about a ring center axis 16 .

[0068] Furthermore, the shifting device 10 comprises a first friction fit ring 18 , a second friction fit ring 20 , a third friction fit ring 22 and an actuation ring 24 , wherein the first friction fit ring is fixed against rotation and along the ring center axis 16 Displaceably coupled to the second coupling member 14, the second friction fit ring is rotationally fixed and displaceably coupled to the first coupling member 12 along the ring central axis 16, the third friction fit ring The actuating ring is coupled in a rotationally fixed manner and displaceable along the ring center axis 16 to the second coupling member 14 , and the actuating rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com