Float-bowl type lifting valve for filter tank

A buoy type, lifting valve technology, applied in the direction of lifting valve, valve details, valve device, etc., can solve the problems of fixed drain height, large loss of filter material, and inability to adapt to the change of filter liquid level, so as to reduce the number of backwashing , high backwashing efficiency and shortened backwashing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings and specific embodiments. The specific content listed in the following embodiments is not limited to the technical features necessary for the technical problem to be solved by the technical solution described in the claims. Meanwhile, the enumeration is only a part of the present invention, not all of the embodiments.

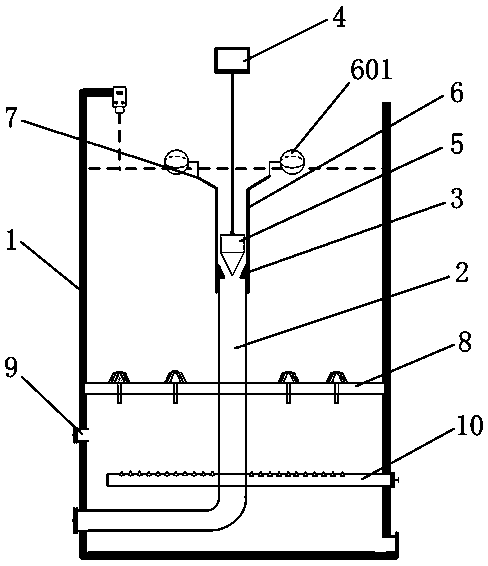

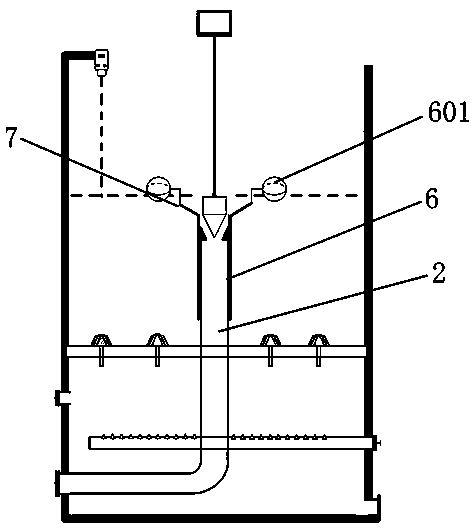

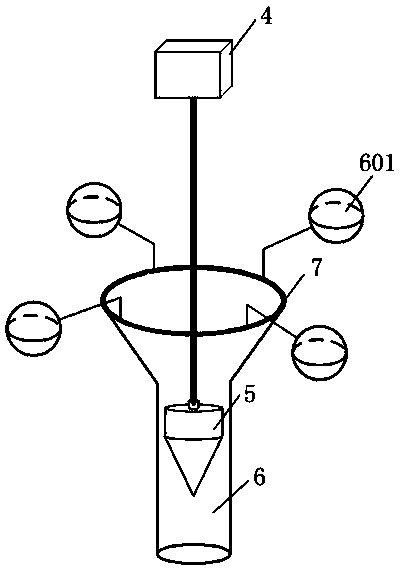

[0022] Such as figure 1 As shown, the buoy type lift valve of the present invention is arranged in the filter tank, and it comprises a vertical water inlet and outlet pipe 2, and this water inlet and outlet pipe 2 is used for the water to be filtered to enter the filter tank, and is also used as a drain in the backwashing process pipe for backwash water to flow out of the filter. The water inlet and outlet pipes 2 are preferably arranged at the center of the filter tank 1, so that impurities on the liquid surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com