Special hair sample imaging scanner for measuring hair fineness and length

A technology of length measurement and scanner, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems of backward measuring methods, time-consuming, cost-intensive, etc., and achieve the effects of improving measurement accuracy, saving labor and cost, and ensuring high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

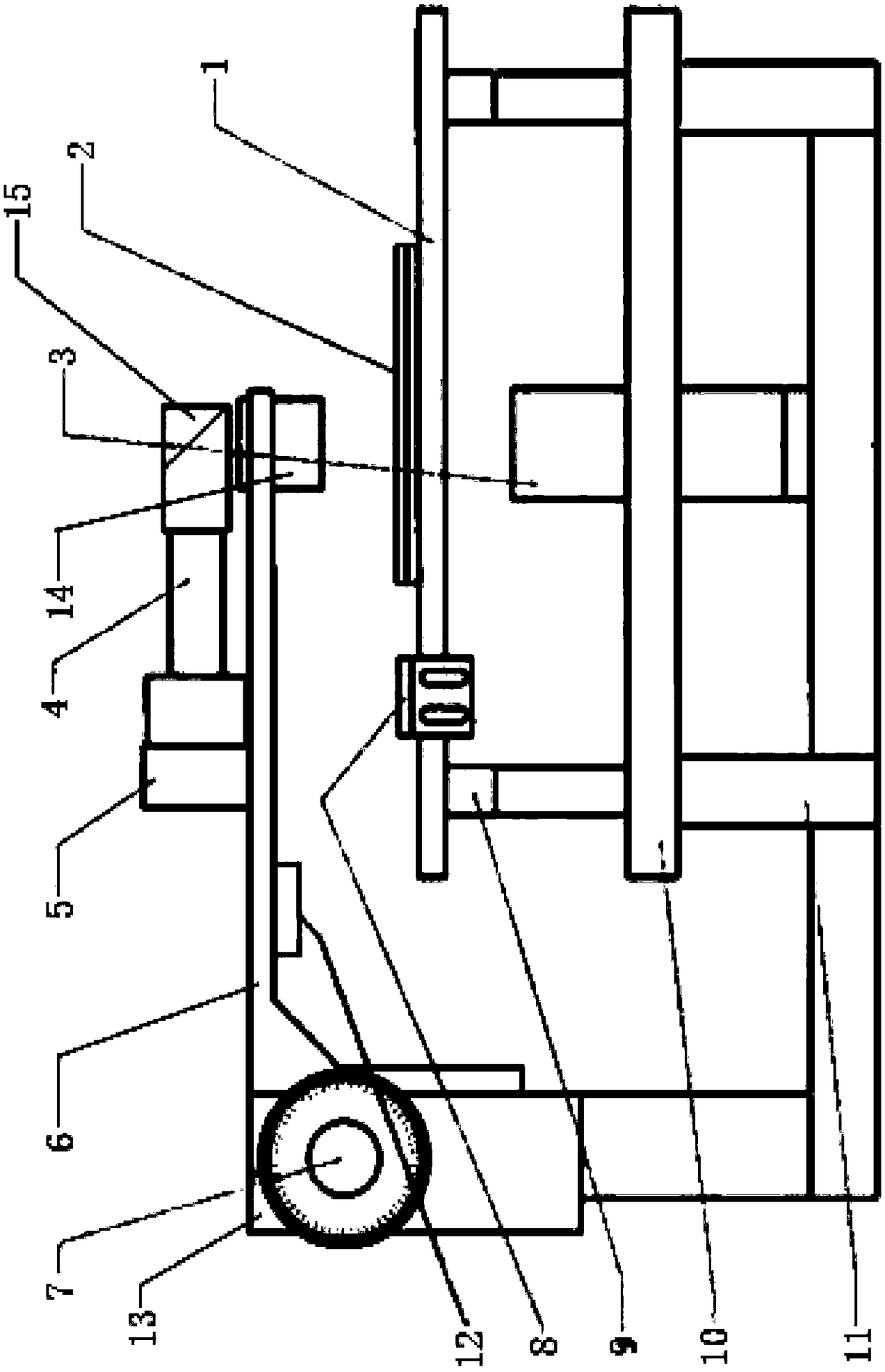

[0008] A special plush sample imaging scanner for measuring the fineness and length of plush, such as figure 1 As shown, a longitudinal rail 10 is fixed horizontally on the base 11, and a first linear motor, a first displacement sensor, and a longitudinal movement driven by the first linear motor to reciprocate and linearly move along the longitudinal rail 10 are mounted on the longitudinal rail 10. The platform is horizontally fixed with a transverse rail 9 on the longitudinal mobile platform, and is equipped with a second linear motor, a second displacement sensor and a lateral movement driven by the second linear motor to reciprocate and linearly move along the transverse track 9 on the transverse track 9. Bench, the sensor can feed back the displacement parameters of the vertical mobile bench and the lateral mobile bench to the chip mainboard which functions as a controller in real time, the vertical track 10 and the horizontal track 9 are vertical to each other, and a tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com