A kind of detection method of tyramine content in fermented meat products

A technology for fermented meat products and a detection method, which is applied in the field of ultra-high performance liquid chromatography detection of tyramine content in fermented meat products, can solve the problems of difficult operation, complicated pretreatment steps and the like, and achieves a low detection limit and a simple and reliable method. , the effect of simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

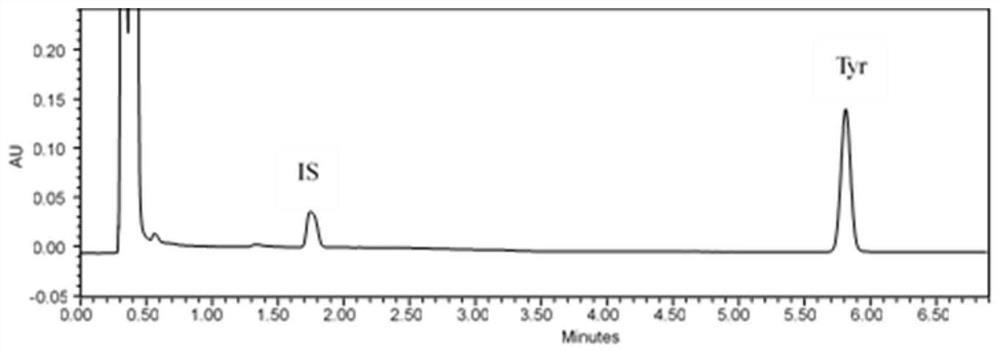

Image

Examples

Embodiment 1

[0022] (a) Pretreatment of the sample solution: take the fermented meat product and cut it into minced meat, weigh 2.0 g of a uniform sample, add 15.0 mL of 5% trichloroacetic acid and homogenize it with a dispersing homogenizer for 1.0 min, centrifuge at 4000 rpm for 10.0 min on a centrifuge, and precipitate After adding 10.0 mL of 5% trichloroacetic acid and homogenizing and centrifuging twice, the combined supernatants were distilled to 50 mL with 5% trichloroacetic acid, and the extract was filtered with a microporous membrane of 0.22 μm and stored at 4°C for later use.

[0023] (b) Derivatization reaction of the sample: take 100 μl sample from the filtrate, add 10 μg·mL -1 100 μl of internal standard solution, then add 100 μl of saturated sodium bicarbonate with sodium hydroxide to adjust the pH value to 10, and 2.0 mg·mL prepared with acetone -1 With 200 μl of dansyl chloride, the derivatization reaction was carried out at 55° C. in the dark for 15.0 minutes. After the ...

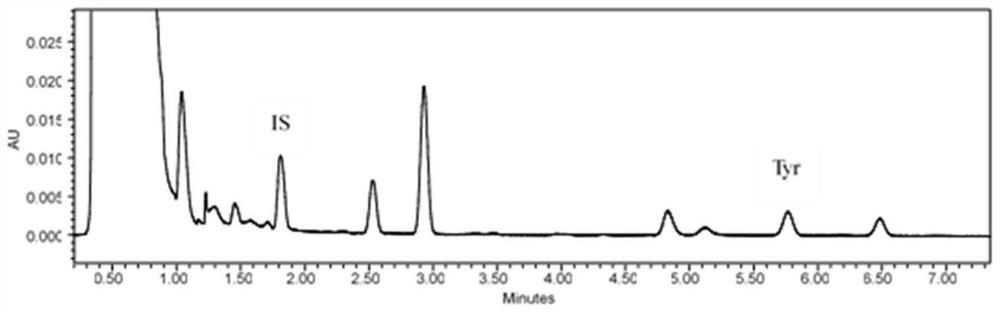

Embodiment 2

[0029] (a) Pretreatment of the sample solution: take the fermented meat product and cut it into minced meat, weigh 5.0 g of a uniform sample, add 25.0 mL of 5% trichloroacetic acid and homogenize it with a dispersing homogenizer for 1.0 min, centrifuge at 4000 rpm for 10.0 min on a centrifuge, and precipitate After adding 15.0 mL of 5% trichloroacetic acid again and centrifuging twice, the combined supernatants were distilled to 50 mL with 5% trichloroacetic acid, and the extract was filtered with a microporous membrane of 0.22 μm and stored at 4°C for later use.

[0030](b) Derivatization reaction of the sample: take 100 μl sample from the filtrate, add 10 μg·mL -1 Internal standard solution 100 μl, then add 100 μl of saturated sodium bicarbonate with sodium hydroxide to adjust the pH value to 10, and 3 mg·mL prepared with acetone -1 With 200 μl of dansyl chloride, the derivatization reaction was carried out at 50° C. in the dark for 20.0 minutes. After the reaction was comp...

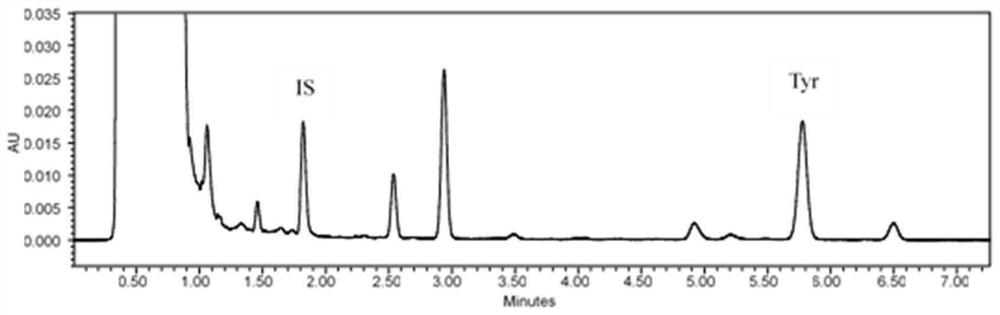

Embodiment 3

[0036] (a) Pretreatment of the sample solution: take the fermented meat product and cut it into minced meat, weigh 3.0 g of a uniform sample, add 20.0 mL of 5% trichloroacetic acid and homogenize it with a dispersing homogenizer for 1.0 min, centrifuge at 4000 rpm for 10.0 min on a centrifuge, and precipitate After adding 10.0 mL of 5% trichloroacetic acid and homogenizing and centrifuging twice, the combined supernatants were distilled to 50 mL with 5% trichloroacetic acid, and the extract was filtered with a microporous membrane of 0.22 μm and stored at 4°C for later use.

[0037] (b) Derivatization reaction of the sample: take 100 μl sample from the filtrate, add 10 μg·mL -1 100 μl of internal standard solution, then add 100 μl of saturated sodium bicarbonate with sodium hydroxide to adjust the pH value to 10, and 5.0 mg·mL prepared with acetone -1 With 200 μl of dansyl chloride, the derivatization reaction was carried out at 60° C. in the dark for 10.0 minutes. After the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com