Method for detecting content of tyramine in fermented meat product

A technology for fermented meat products and a detection method, which is applied in the field of ultra-high performance liquid chromatography detection of tyramine content in fermented meat products, can solve problems such as difficult operation and cumbersome pretreatment steps, achieve low detection limit, and simple and reliable method , good repeatability and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

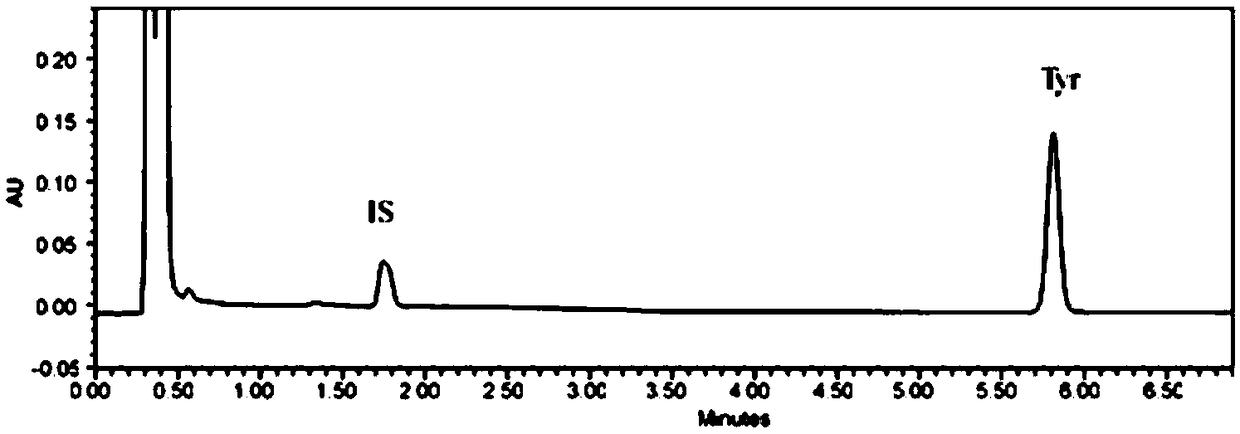

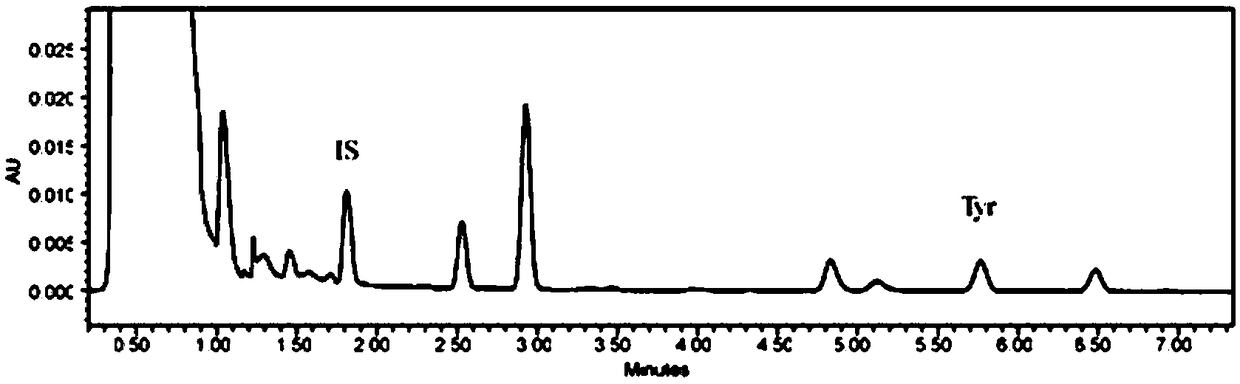

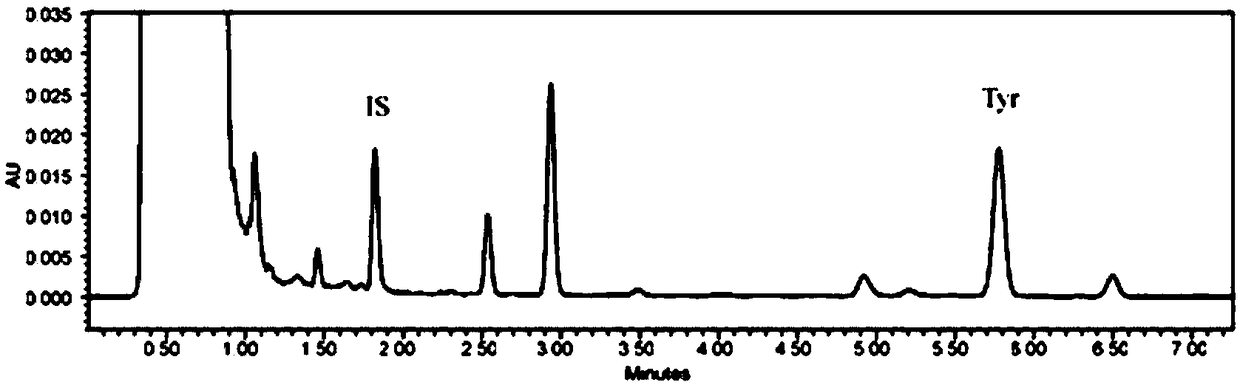

Image

Examples

Embodiment 1

[0022] (a) Pretreatment of the sample solution: take the fermented meat product and cut it into minced meat, weigh 2.0 g of a uniform sample, add 15.0 mL of 5% trichloroacetic acid and homogenize it with a dispersing homogenizer for 1.0 min, centrifuge at 4000 rpm for 10.0 min on a centrifuge, and precipitate After adding 10.0 mL of 5% trichloroacetic acid and homogenizing and centrifuging twice, the combined supernatants were distilled to 50 mL with 5% trichloroacetic acid, and the extract was filtered with a microporous membrane of 0.22 μm and stored at 4°C for later use.

[0023] (b) Derivatization reaction of the sample: take 100 μl sample from the filtrate, add 10 μg·mL -1 100 μl of internal standard solution, then add 100 μl of saturated sodium bicarbonate with sodium hydroxide to adjust the pH value to 10, and 2.0 mg·mL prepared with acetone -1 With 200 μl of dansyl chloride, the derivatization reaction was carried out at 55° C. in the dark for 15.0 minutes. After the ...

Embodiment 2

[0029] (a) Pretreatment of the sample solution: take the fermented meat product and cut it into minced meat, weigh 5.0 g of a uniform sample, add 25.0 mL of 5% trichloroacetic acid and homogenize it with a dispersing homogenizer for 1.0 min, centrifuge at 4000 rpm for 10.0 min on a centrifuge, and precipitate After adding 15.0 mL of 5% trichloroacetic acid again and centrifuging twice, the combined supernatants were distilled to 50 mL with 5% trichloroacetic acid, and the extract was filtered through a 0.22 μm microporous membrane and stored at 4°C for later use.

[0030](b) Derivatization reaction of the sample: take 100 μl sample from the filtrate, add 10 μg·mL -1 Internal standard solution 100 μl, then add 100 μl of saturated sodium bicarbonate with sodium hydroxide to adjust the pH value to 10, and 3 mg·mL prepared with acetone -1 With 200 μl of dansyl chloride, the derivatization reaction was carried out at 50° C. in the dark for 20.0 minutes. After the reaction was comp...

Embodiment 3

[0036] (a) Pretreatment of the sample solution: take the fermented meat product and cut it into minced meat, weigh 3.0 g of a uniform sample, add 20.0 mL of 5% trichloroacetic acid and homogenize it with a dispersing homogenizer for 1.0 min, centrifuge at 4000 rpm for 10.0 min on a centrifuge, and precipitate After adding 10.0 mL of 5% trichloroacetic acid and homogenizing and centrifuging twice, the combined supernatants were distilled to 50 mL with 5% trichloroacetic acid, and the extract was filtered with a microporous membrane of 0.22 μm and stored at 4°C for later use.

[0037] (b) Derivatization reaction of the sample: take 100 μl sample from the filtrate, add 10 μg·mL -1 100 μl of internal standard solution, then add 100 μl of saturated sodium bicarbonate with sodium hydroxide to adjust the pH value to 10, and 5.0 mg·mL prepared with acetone -1 With 200 μl of dansyl chloride, the derivatization reaction was carried out at 60° C. in the dark for 10.0 minutes. After the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com