Efficient stone crusher for mines

A high-efficiency crushing and stone crusher technology, applied in the field of mechanical equipment, can solve the problems of labor consumption, crushing roller stop, high labor intensity, etc., and achieve the effect of avoiding load increase, prolonging service life and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

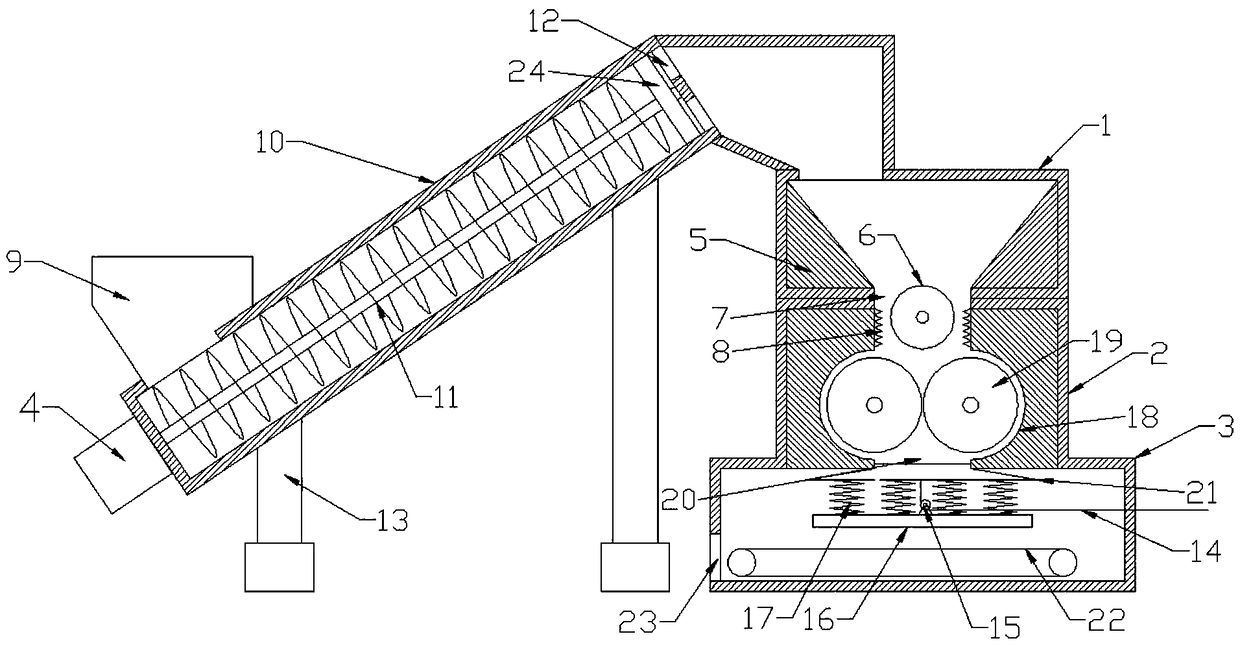

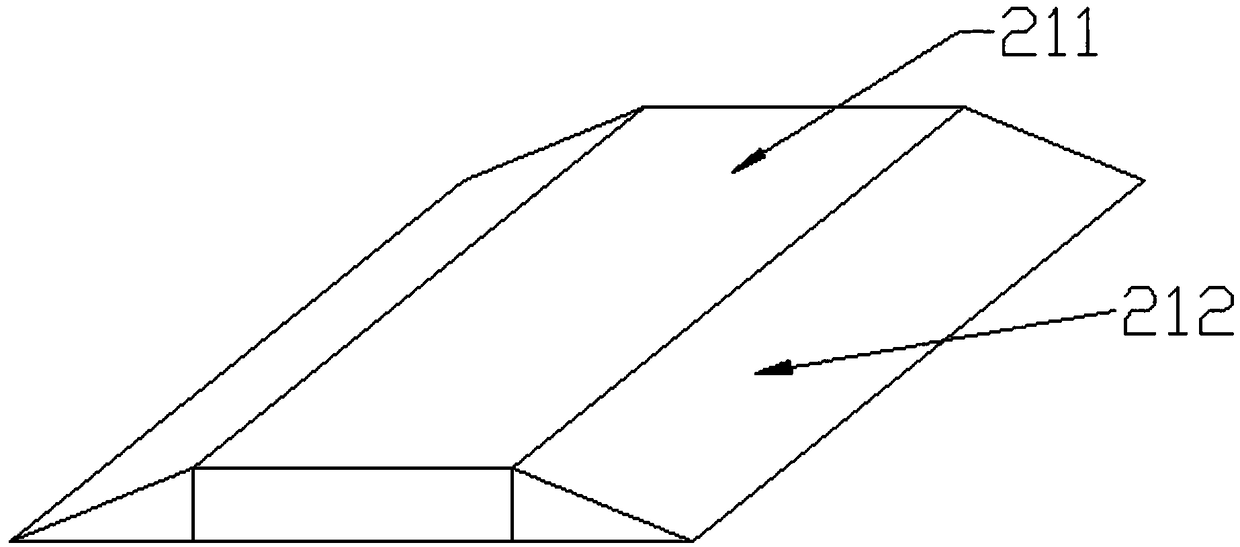

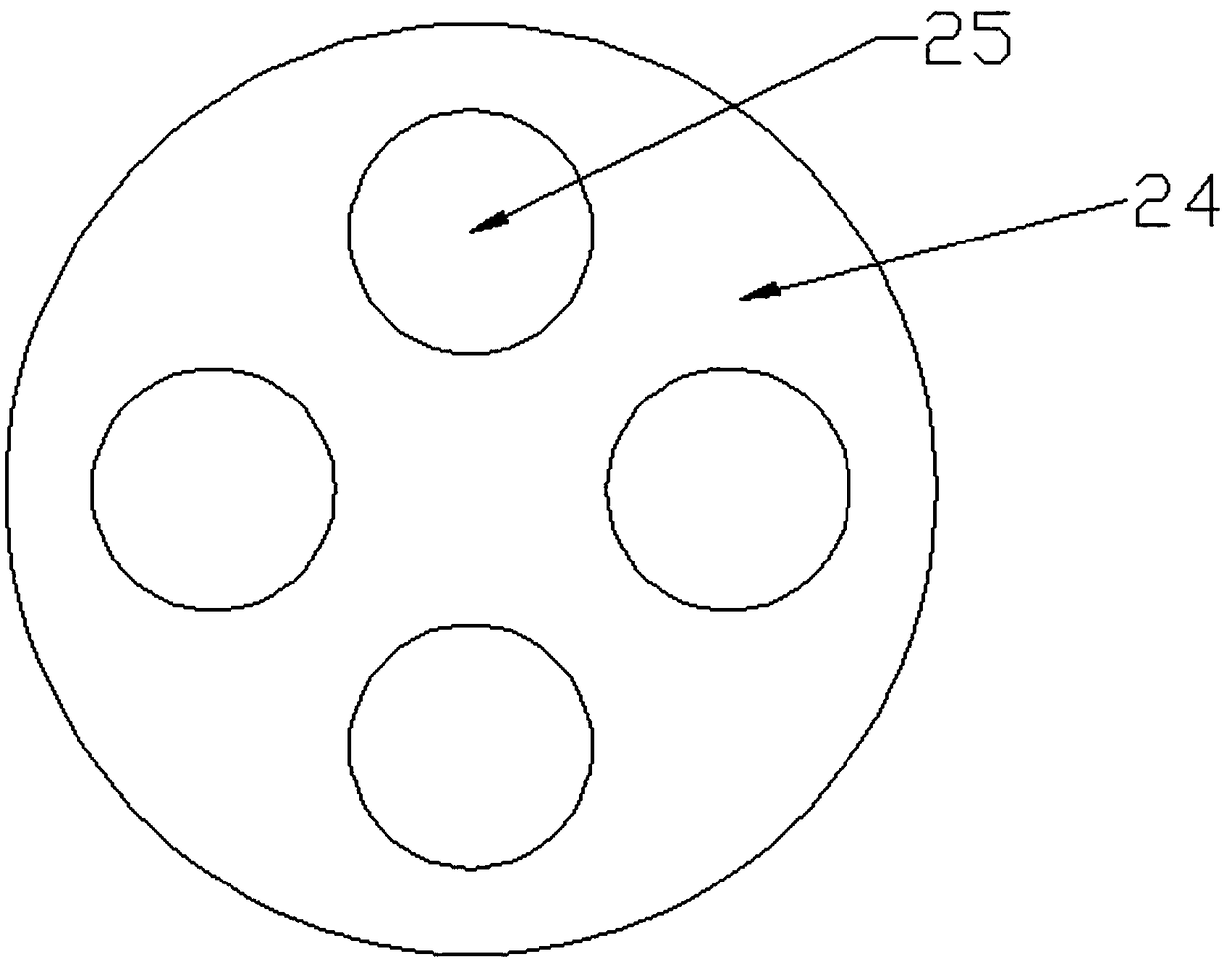

[0017] Please refer to the figure, in the embodiment of the present invention, a kind of high-efficiency crushing stone crusher for mines includes a pre-crushing box 1, a crushing box 2, a collection box 3, a feeding motor 4, a feeding hopper 9 and a feeding cylinder 10; The pre-crushing box 1 is fixed on the top of the crushing box 2, and the crushing box 2 is fixed on the top of the collection box 3. On the top of the pre-crushing box 1, it communicates with the upper end of the feeding tube 10 inclined downward. On the lower side wall of the feeding tube 10 Outriggers 13 are fixed to support the feeding cylinder 10. A feeding hopper 9 is connected to the upper side of the lower end of the feeding cylinder 10, and stones are loaded into the feeding cylinder 10. A feeding motor 4 is fixedly installed at the end of the feeding cylinder 10 to feed the material. The output shaft of motor 4 stretches in the feeding cylinder 10, and the output shaft of feeding motor 4 coincides wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com