Flow-line type automatic dispensing, roasting and reinforcing device for connecting line welding spot

A flow-type, semi-automatic technology, used in devices and coatings that apply liquid to the surface, can solve problems such as low efficiency, deviation of product dispensing position, affecting dispensing effect, etc. Precise control, easy dispensing position effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

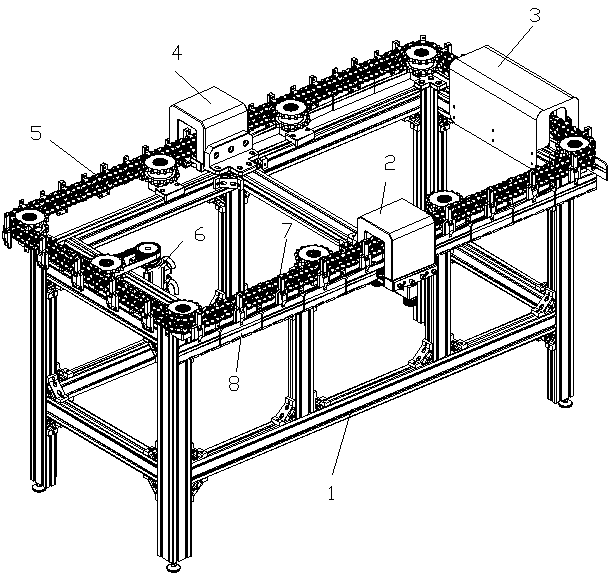

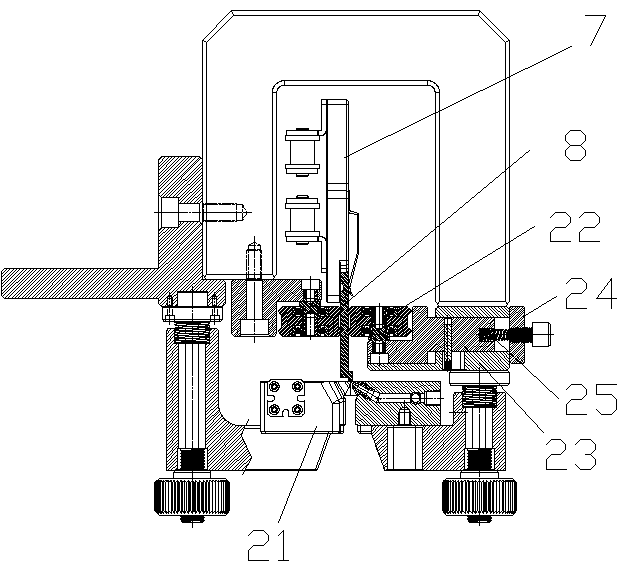

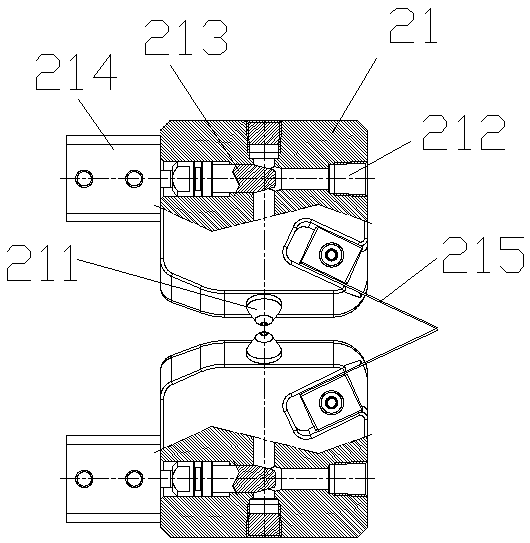

[0024] Such as Figure 1-Figure 5 As shown, a flow-type semi-automatic glue dispensing, baking and strengthening equipment for connecting wire solder joints includes a base 1 on which a dispensing mechanism 2, a light oven 3, a discharge mechanism 4 and passing through the points in turn are arranged. The conveyor belt 5 of the glue mechanism 2, the light oven 3, and the unloading mechanism 4, the conveyor belt 5 is provided with a plurality of fixture fixing devices 7 for fixing the product fixing fixture 8; the glue dispensing mechanism 2 includes a product fixing fixture There are rubber seats 21 on both sides of the travel route of the tool 8, and a glue injection nozzle 211 communicating with a glue injection channel 212 is arranged on the glue seat 21 .

[0025] By passing the conveyor belt equipped with the jig fixing device through the dispensing mechanism, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com