Dispensing and drying all-in-one machine for PCBA board

An all-in-one machine and dispensing technology, which is applied in the direction of conveyor objects, devices for coating liquid on the surface, furnaces, etc., can solve the problems of artificial transfer damage of PCBA boards, low placement efficiency, and large occupied area to avoid pollution Or the effect of artificially transferring damage, improving discharge efficiency, and low occupancy rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

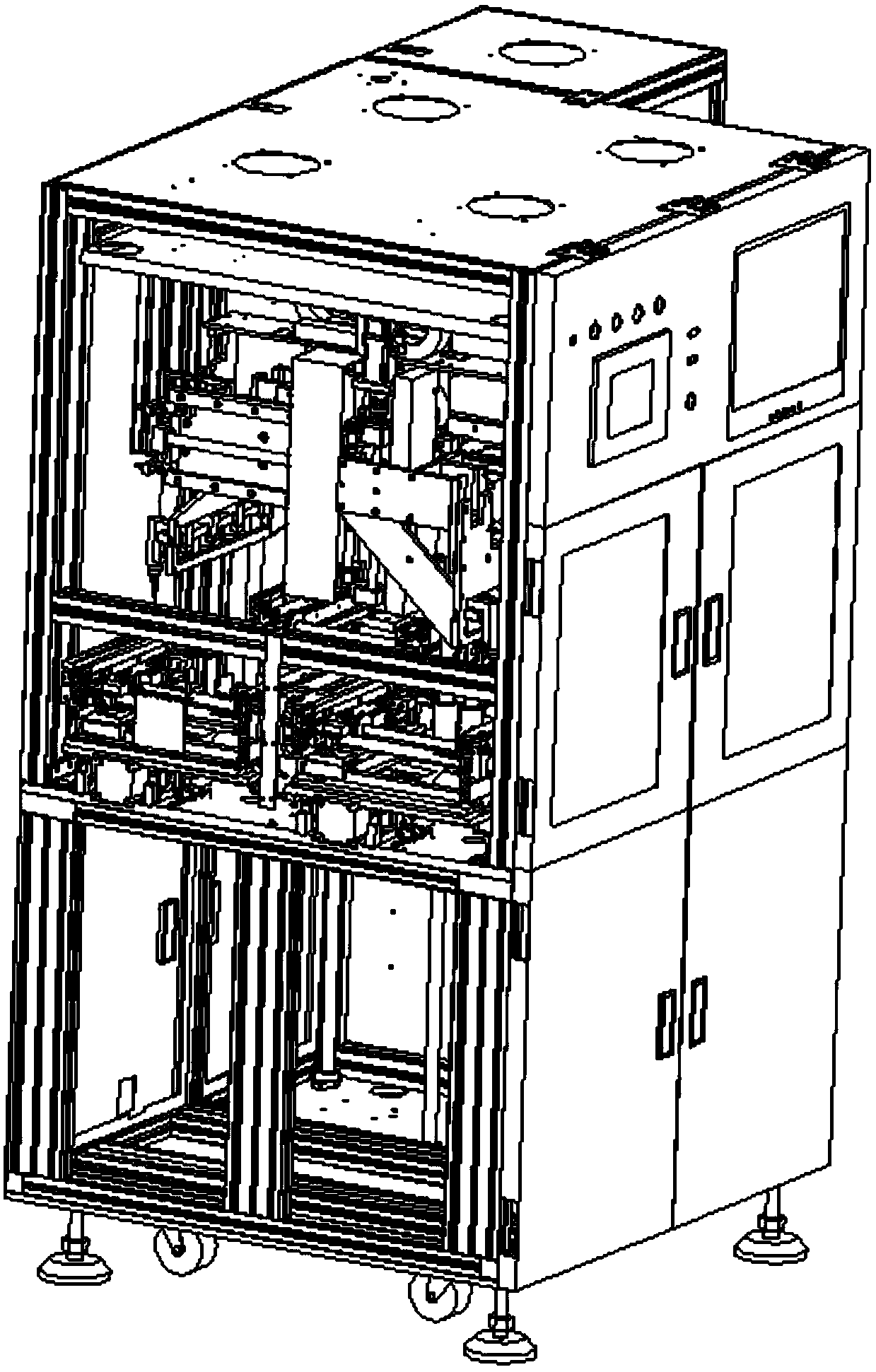

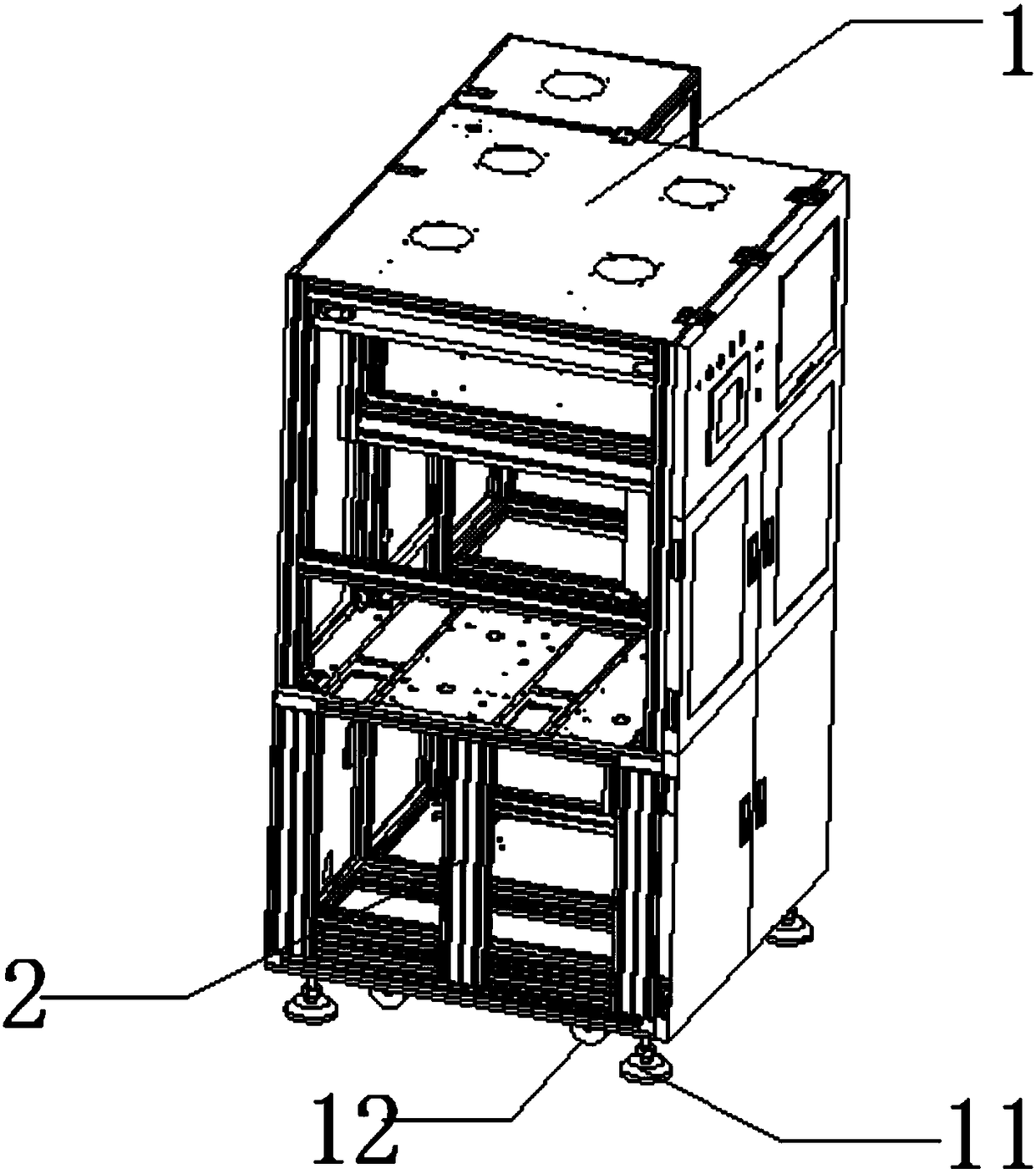

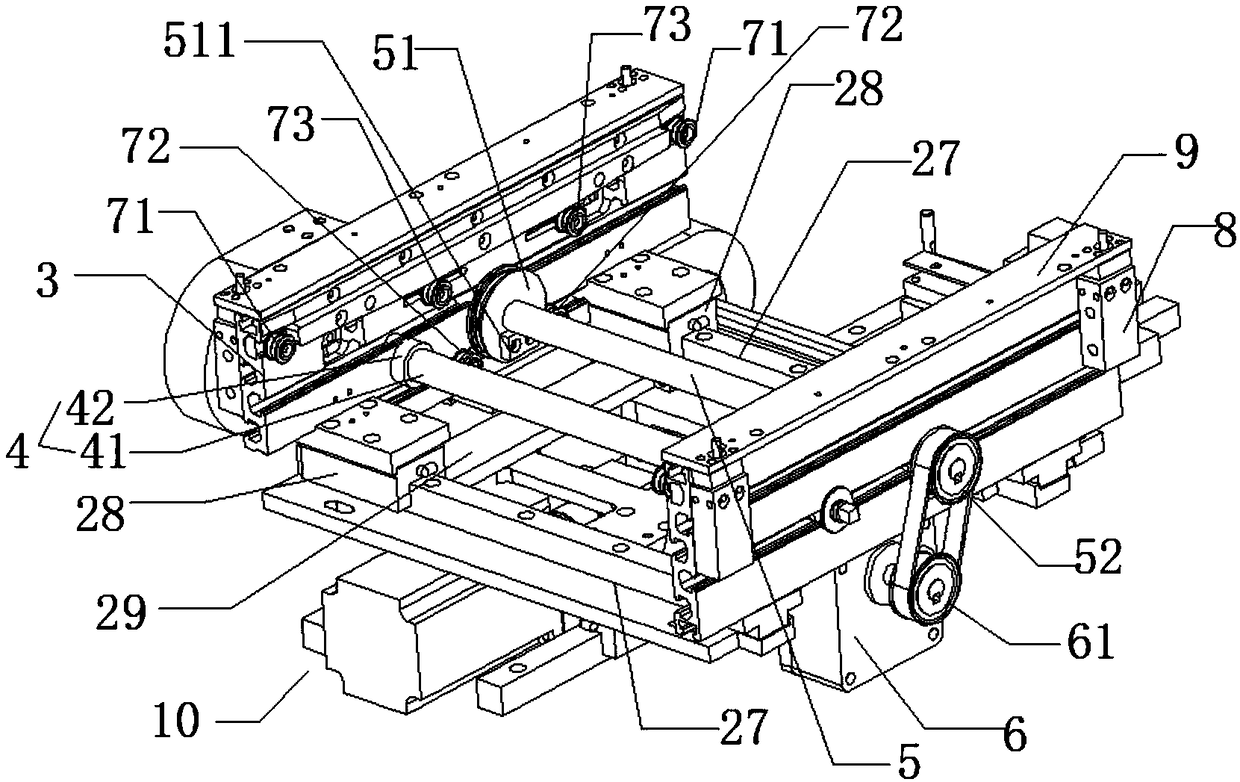

[0043] A dispensing and drying integrated machine for PCBA boards, including: a rack, a feeding module, a lifting module, a discharging module, a dispensing module, and a drying module;

[0044] The frame includes an outer shell 1 with an opening on one side and a support frame 2 inside the outer shell 1. The four corners of the lower end of the outer shell 1 are fixedly installed with telescopic feet 11, and the lower end of the outer shell 1 is close to the four corners. All positions are installed with universal casters 12, fixed feet 11 are used to fix the dispensing and drying integrated machine, and the universal casters 12 are used for the flexible movement of the dispensing and drying integrated machine. When the internal layout of the production workshop needs to be adjusted, The position in the workshop can be changed at any time through the universal caster 12, without the disassembly and installation process of the dispensing and drying station. The feeding module, the...

specific Embodiment example 2

[0060] A dispensing and drying integrated machine for PCBA boards, including: a rack, a feeding module, a lifting module, a discharging module, a dispensing module, and a drying module;

[0061] The frame includes an outer shell 1 with an opening on one side and a support frame 2 inside the outer shell 1. The four corners of the lower end of the outer shell 1 are fixedly installed with telescopic feet 11, and the lower end of the outer shell 1 is close to the four corners. All positions are installed with universal casters 12, fixed feet 11 are used to fix the dispensing and drying integrated machine, and the universal casters 12 are used for the flexible movement of the dispensing and drying integrated machine. When the internal layout of the production workshop needs to be adjusted, The position in the workshop can be changed at any time through the universal caster 12, without the disassembly and installation process of the dispensing and drying station. The feeding module, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com