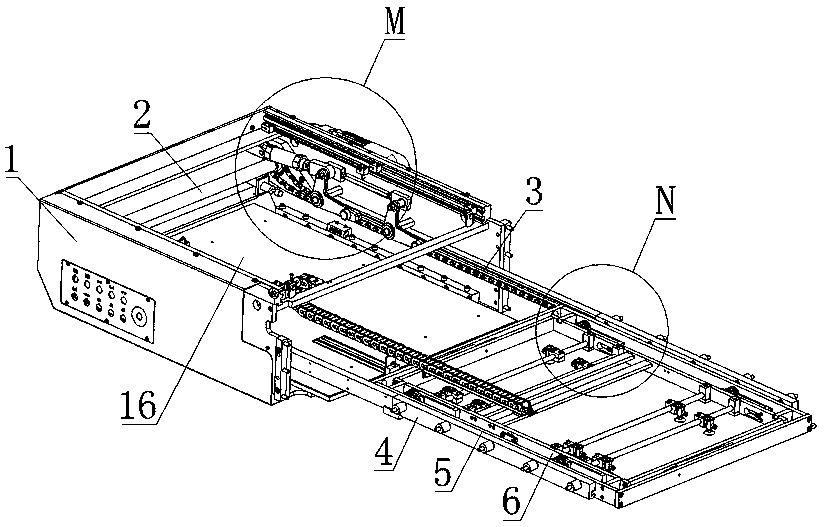

All-waste-removing paper paving device of die-cutting machine

A technology for die-cutting machines and waste cleaning, which is applied in metal processing and other directions, and can solve problems such as overturning, unfavorable stacking storage and flow of die-cut products, and tilting of die-cut products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

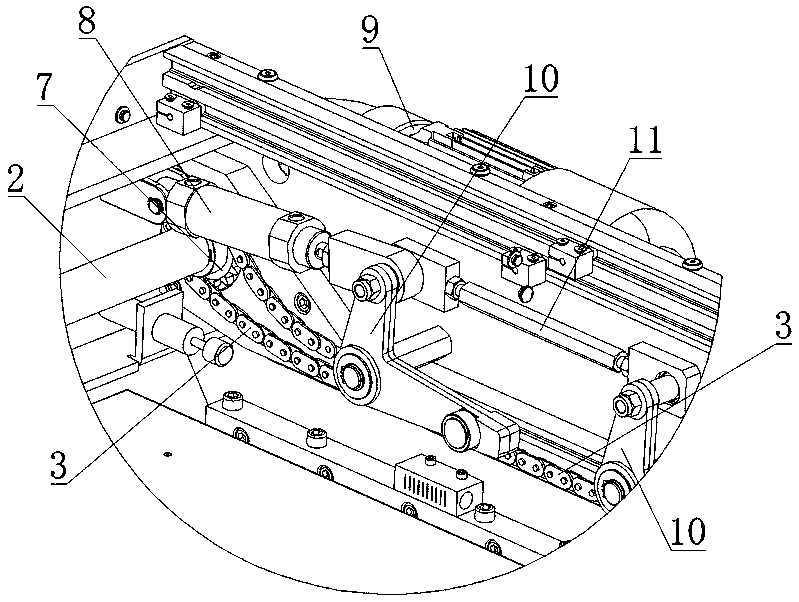

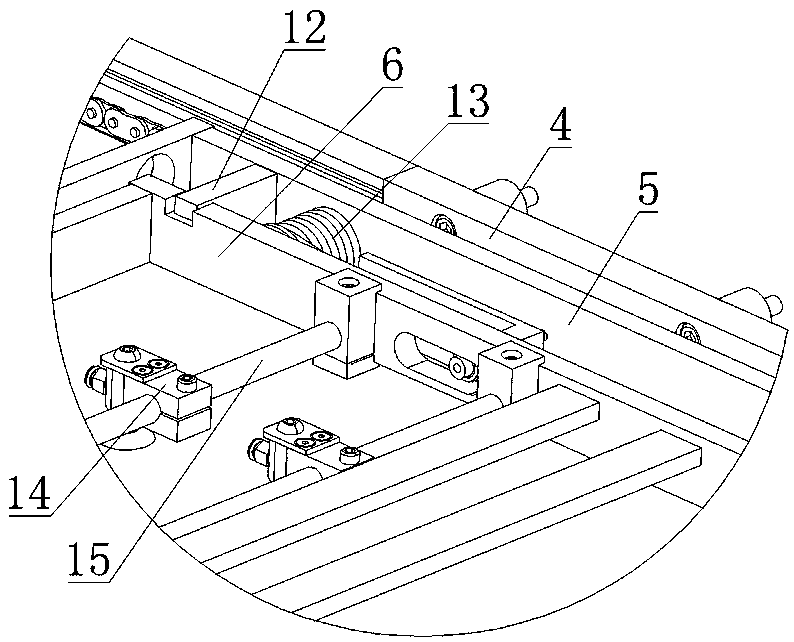

[0018] As shown in the figure, the paper laying device of the full cleaning die-cutting machine disclosed by the present invention includes a frame 1, a moving frame 5 and a paper suction frame 6, and a cardboard 16 is arranged in the frame 1, and stacked on the cardboard 16. Paper is provided with guide rails 4 on both sides of the frame 1 and extends outward. The mobile frame 5 is arranged on the guide rails 4 and driven by a drive mechanism. The drive mechanism includes a drive motor 9 connected to a sprocket 7. The sprocket 7 is engaged with the chain 3 and connected with the mobile frame 5, the chain 3 is movably arranged on the guide rail 4, so that the chain 3 can better pull the mobile frame 5, and further enhance the stability of the mobile frame 5 action. The paper-absorbing frame 6 can be moved up and down on the movable frame 5 and is connected by an elastic member. The elastic member in this embodiment adopts a torsion spring 13, and one end of the torsion spring i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com