Solid material sealed packaging system after material compressing and baling

A solid material and packaging system technology, applied in the direction of packaging, article rotation wrapping, and binding materials, etc., can solve the problems of unfavorable environmental protection, smelly water droplets, random dripping, etc., to avoid odor emission, avoid dripping, and avoid running Partial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

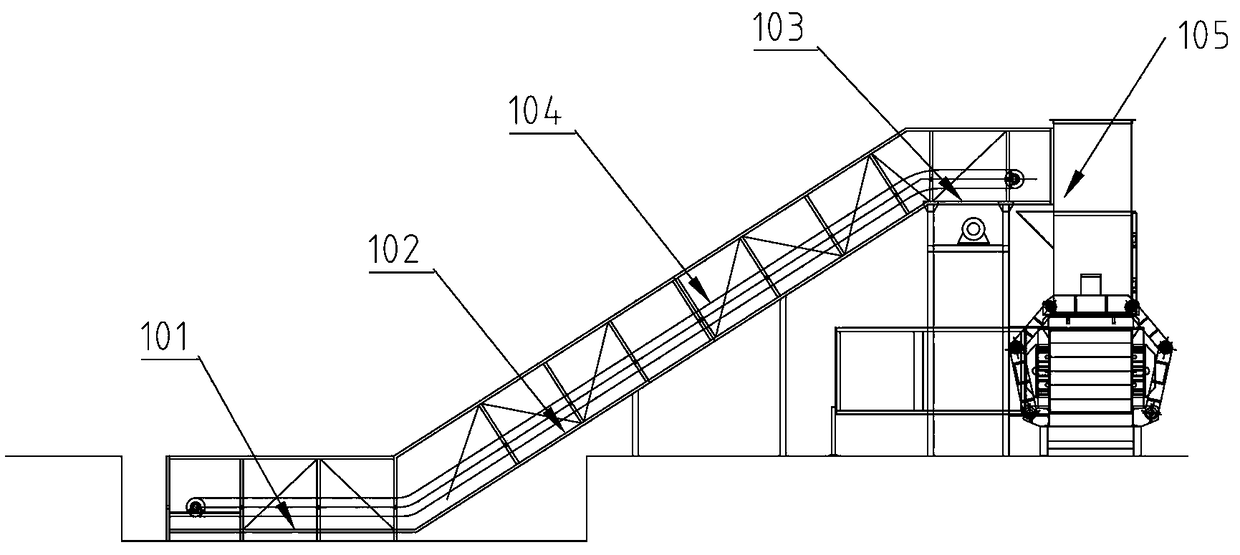

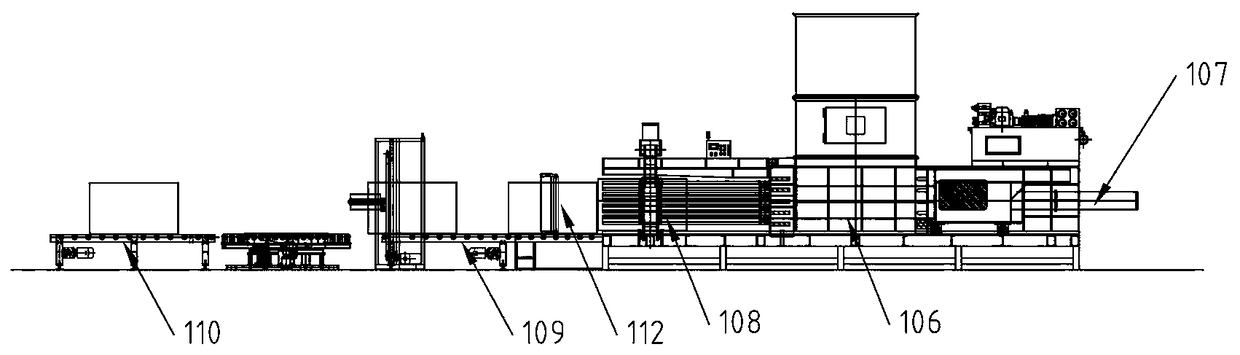

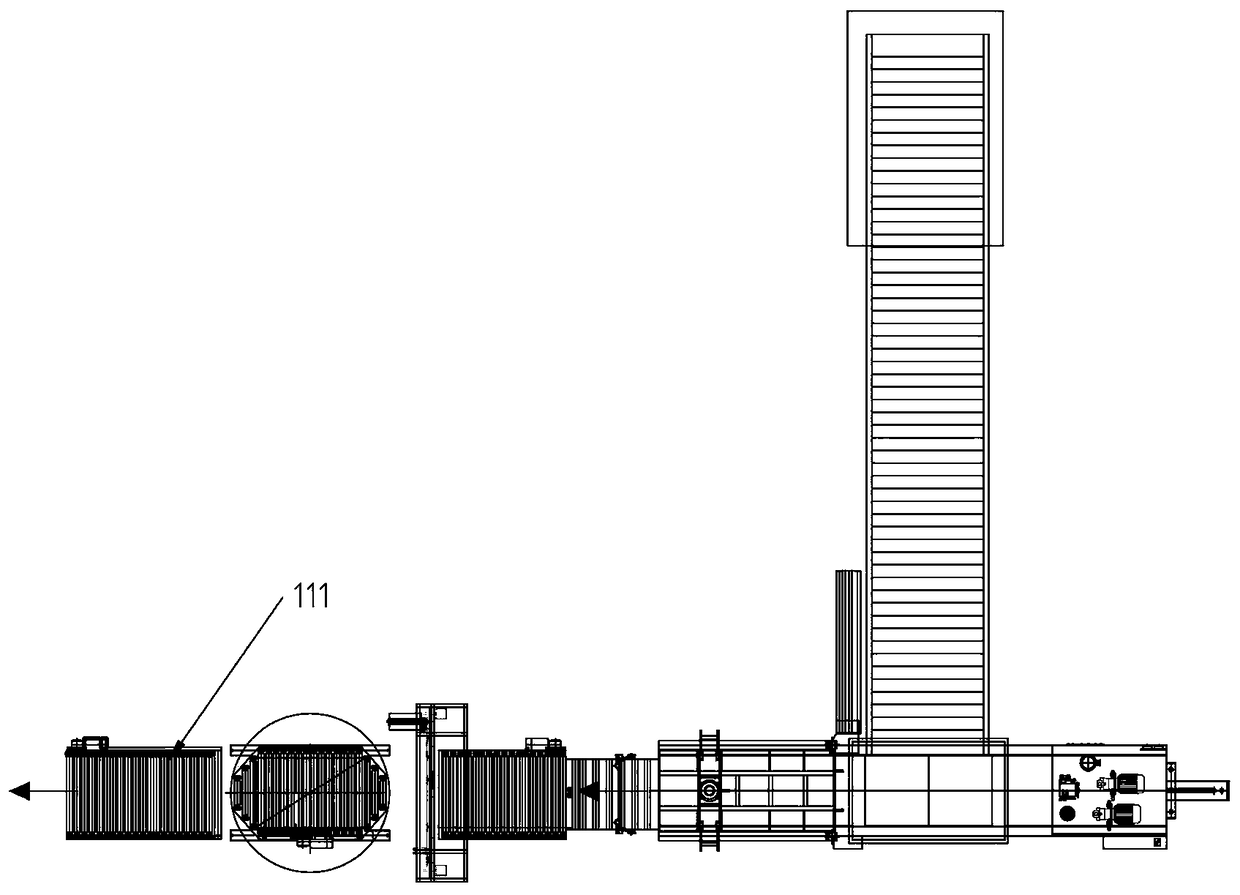

[0040] Such as Figure 1-Figure 10 Shown is a closed packaging system for solid materials compressed and bundled, including

[0041] A feed conveying assembly, which includes a feed conveying support, which includes a lower conveying support 101 horizontally distributed along the solid material conveying direction, an upper conveying support 103 and an inclination connecting the upper and lower conveying supports The conveying support 102 is provided with a chain plate conveying line 104 on the feed conveying support.

[0042] A material box 105 arranged at the discharge end of the chain conveyor line 104 .

[0043] An extrusion molding assembly arranged below the material box 105, the extrusion molding assembly includes a molding box body 106, a cuboid molding cavity is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com