Solid matter removal device and method for removing catalytic cracking oil slurry solid matter

A technology for catalytic cracking oil slurry and solid content, which is applied in the field of catalytic cracking oil slurry solid content removal and solid content removal device, and can solve the problem of poor separation effect, poor raw material properties, and equipment that cannot be used for a long period of time. Stable operation and other issues to achieve the effect of increasing the processing capacity and improving the separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

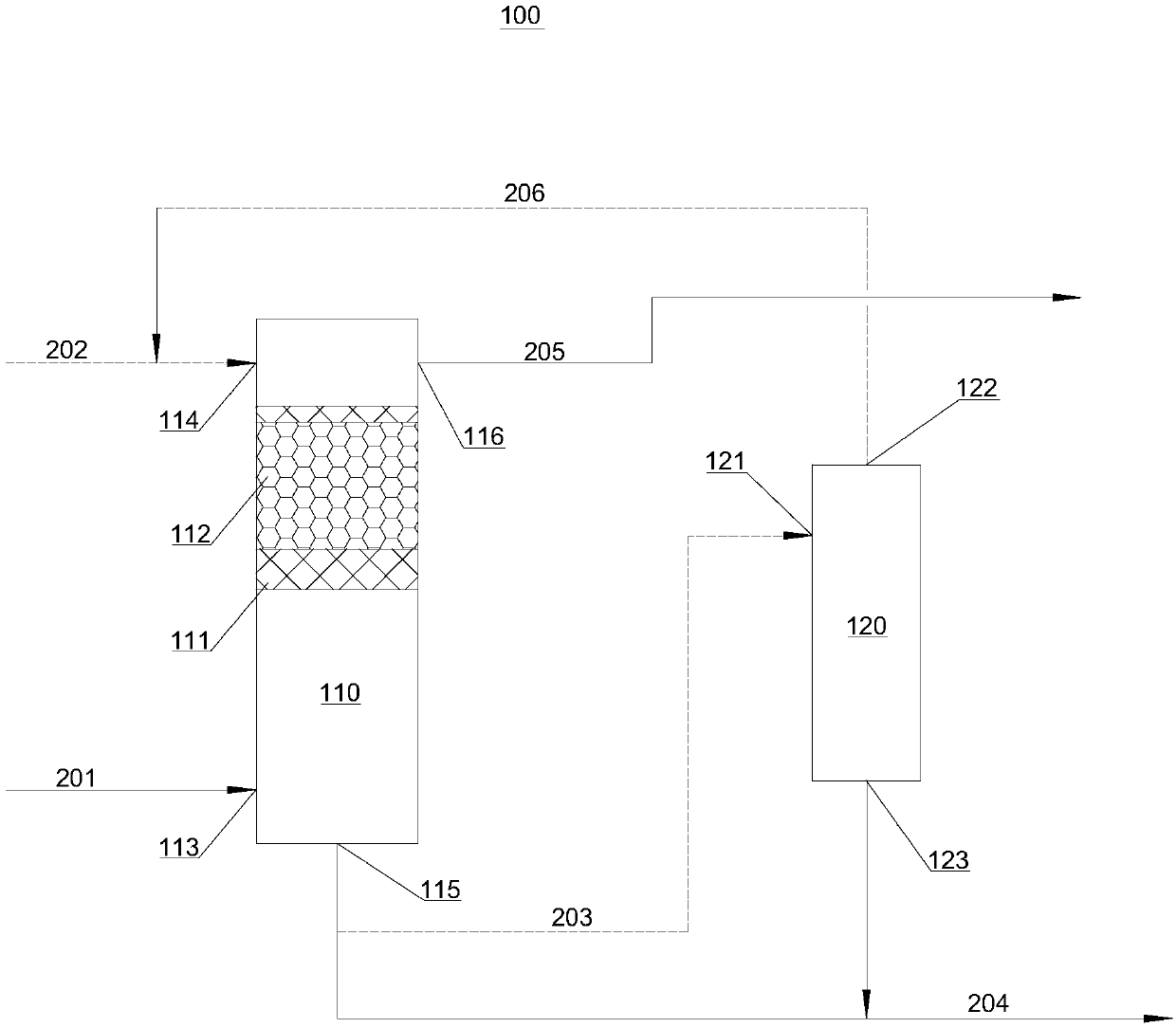

Image

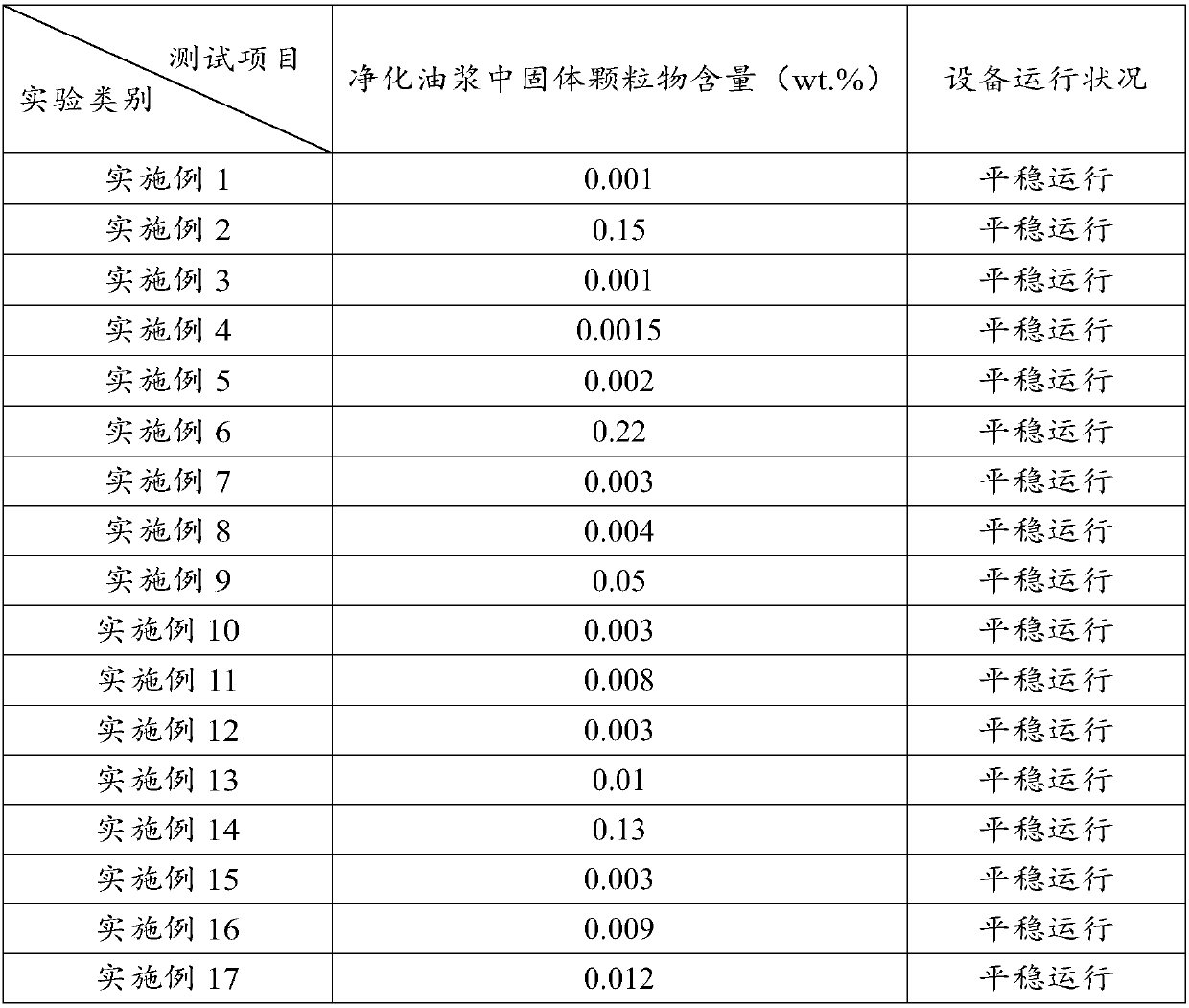

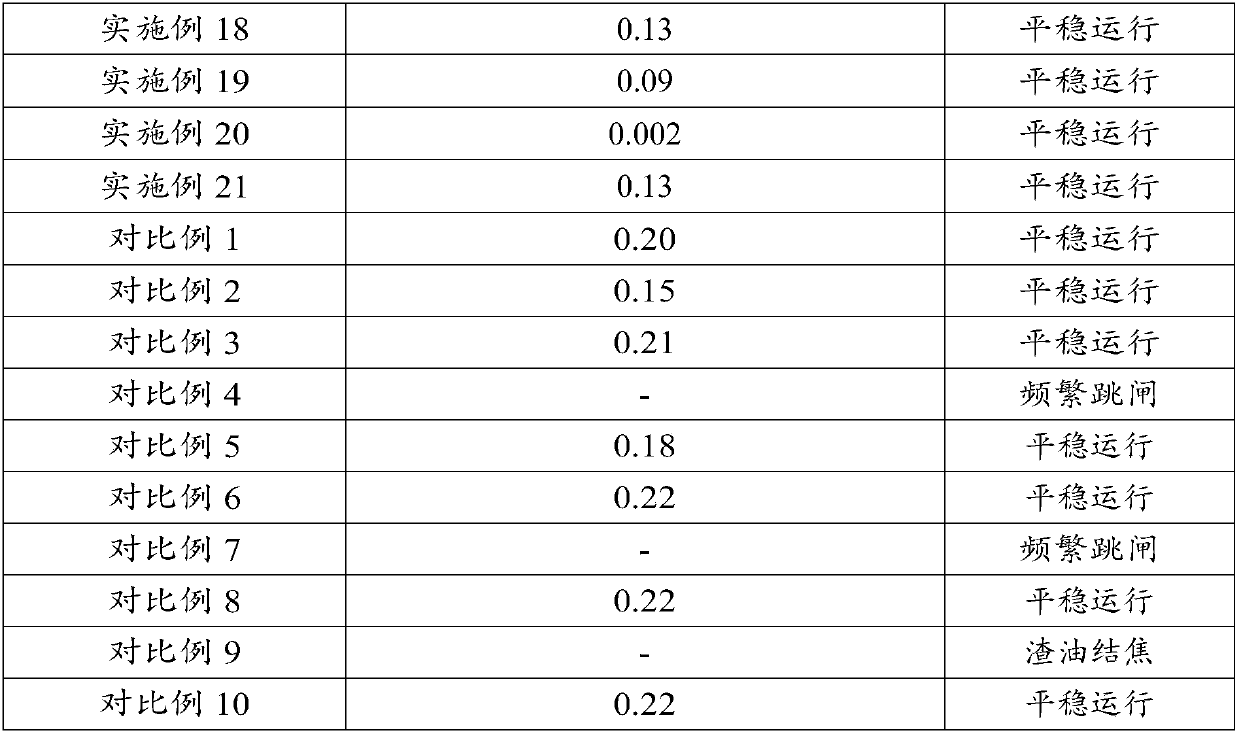

Examples

Embodiment 1

[0053] A method for removing solids in catalytic cracking oil slurry, comprising the following steps:

[0054] The first step is to exchange the heat of the catalytic cracking oil slurry to 200°C;

[0055] In the second step, the oil slurry after heat exchange is transported to the electrostatic separation tank for desolidification treatment. The lower part of the electrostatic separation tank is the electrostatic coalescence part, and its electric field strength is a DC electric field of 8000V / cm; the upper part of the electrostatic separation tank is an electrostatic adsorption part with modified glass beads as the adsorption filler, and its electric field strength is a DC electric field of 5000V / cm; After being treated in an electrostatic separation tank for 2 hours, purified oil slurry and heavy oil slurry are obtained; the heavy oil slurry is directly thrown out;

[0056] The third step is to use naphtha as the backwash solvent to backwash the electrostatic coalescence t...

Embodiment 2-6

[0059] The removal method of the catalytic cracking oil slurry solid content that embodiment 2-6 provides is basically the same as embodiment 1, difference is:

Embodiment 2

[0060] In Example 2, the catalytic cracking oil slurry was heat-exchanged to 80°C;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com