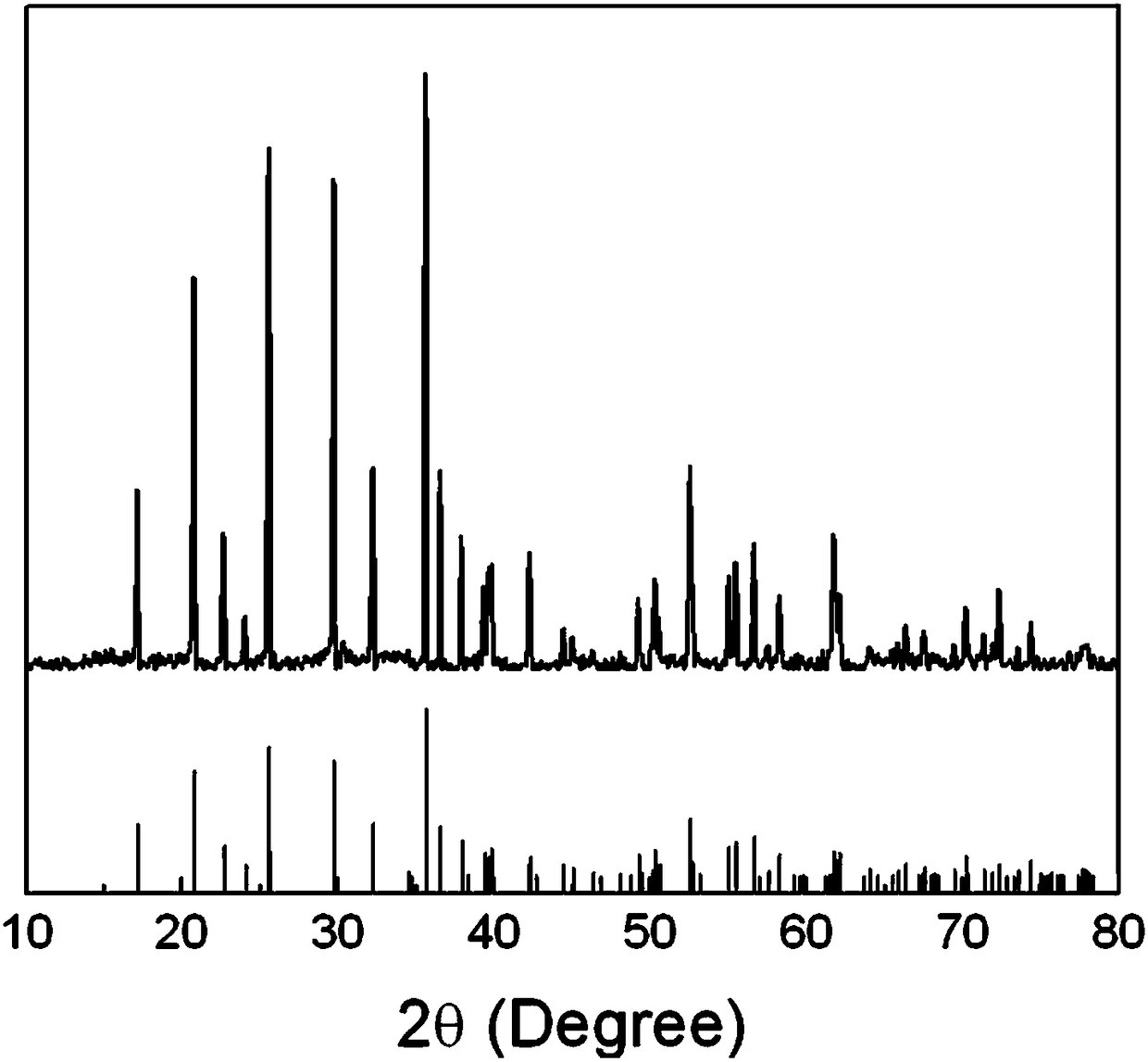

Method for preparing lithium iron phosphate anode material

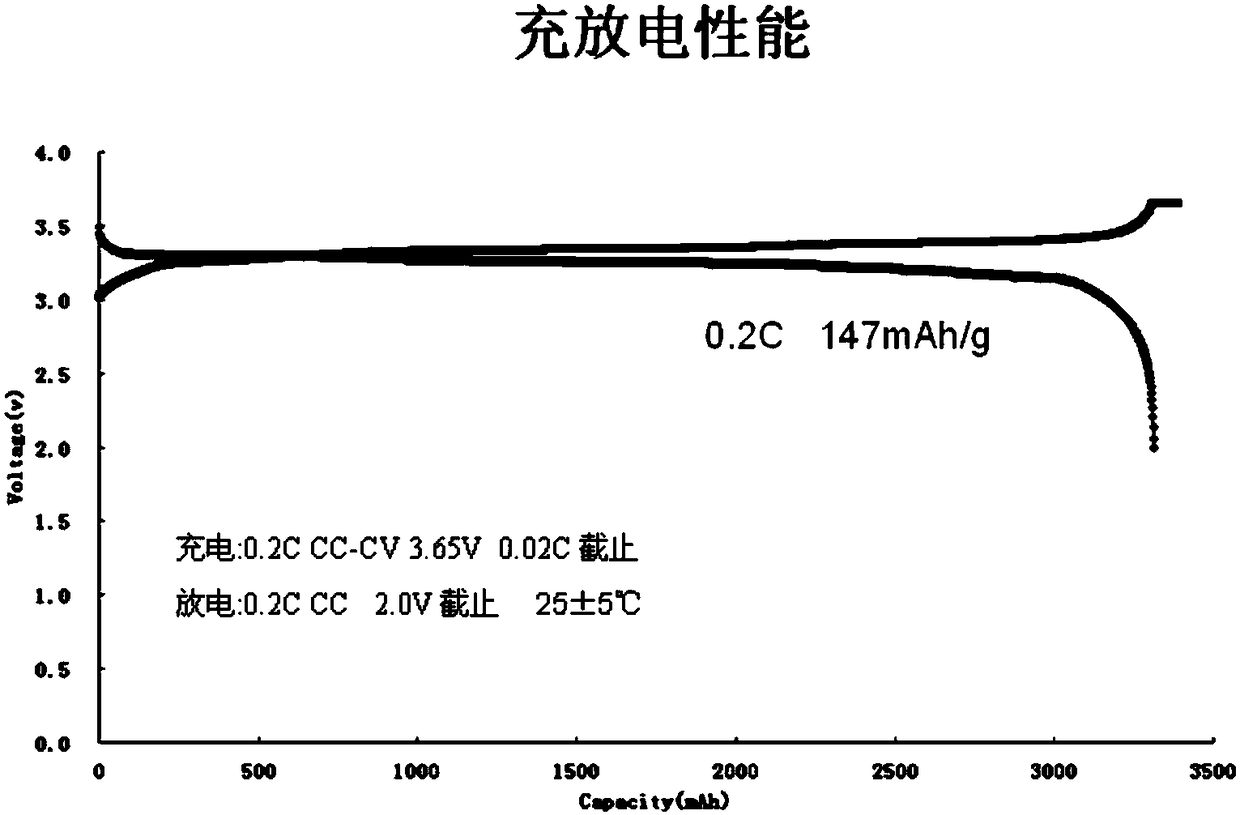

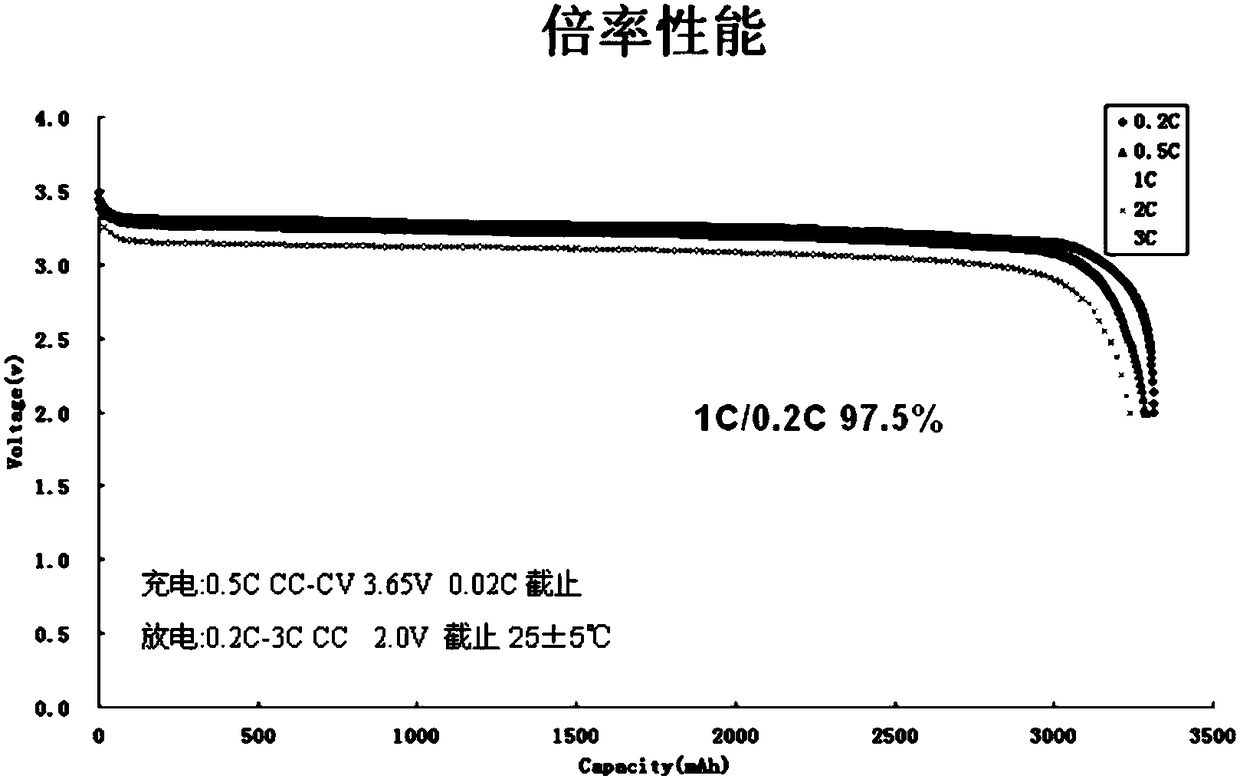

A cathode material, lithium iron phosphate technology, applied in the field of preparation of lithium battery materials, can solve the problems of slow ion diffusion, low electronic conductivity, low compaction density, etc., and achieves good carbon coating effect, simple preparation process, high pressure High solid density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add ferrous sulfate heptahydrate and ammonium dihydrogen phosphate into the reaction kettle containing ammonium water according to the molar ratio of 1:1, the total mass of the solution is 500kg, heat to 100°C for 2 hours, stir at 300r / min, and then Form the ferrophosphorus compound of 50-150nm by chemical crystallization, and then add lithium carbonate, 10% polyethylene glycol and magnesium oxide according to the molar ratio Fe:P:Li=1:1:1. Then use wet ball milling in a ball mill, and pass the MalvernMS2000 laser particle size analyzer to test 50-150nm; use a centrifugal spray drying granulator with an inlet temperature of 230°C and an outlet temperature of 105°C to obtain a spherical precursor; put the precursor into a continuous atmosphere The protection furnace is sintered under the protection of nitrogen gas, the temperature is raised to 400°C at 5°C / h, sintered at a constant temperature of 400°C for 2 hours, and then heated to 650°C at 5°C / h, sintered at a constant...

Embodiment 2

[0038] Add ferrous acetate and lithium dihydrogen phosphate into the reaction kettle containing ammonium water according to the molar ratio of 1:1.2, the total mass of the solution is 500kg, heat to 80°C for 3h, stir at 200r / min, and then form Crystallize to form a 50-150nm ferrophosphorus compound, and then add lithium hydroxide, 10% polyethylene glycol and magnesium oxide according to the molar ratio Fe:P:Li=1:1.2:1.15. Then use wet ball milling in a ball mill, and pass the MalvernMS2000 laser particle size analyzer to test 50-150nm; use a centrifugal spray drying granulator with an inlet temperature of 250°C and an outlet temperature of 100°C to obtain a spherical precursor; put the precursor into a continuous atmosphere The protection furnace is sintered under the protection of nitrogen gas, the temperature is raised to 350°C at 5°C / h, sintered at a constant temperature of 350°C for 3 hours, and then heated to 750°C at 5°C / h, sintered at a constant temperature for 6 hours, ...

Embodiment 3

[0040] Add ferrous nitrate and triammonium phosphate into the reaction kettle containing ammonium water according to the molar ratio of 1:1.1, the total mass of the solution is 500kg, heat it to 120°C for 1 hour, stir at 50r / min, and then form chemical crystals Form a 50-150nm ferrophosphorus compound, then add lithium fluoride, 10% polyethylene glycol and magnesium oxide at a molar ratio of Fe:P:Li=1:1.1:0.95. Then use wet ball milling in a ball mill, and pass the MalvernMS2000 laser particle size analyzer to test 50-150nm; use a centrifugal spray drying granulator with an inlet temperature of 200°C and an outlet temperature of 120°C to obtain a spherical precursor; put the precursor into a continuous atmosphere The protection furnace is sintered under the protection of nitrogen gas, the temperature is raised to 370°C at 5°C / h, sintered at a constant temperature of 370°C for 1 hour, and then heated to 700°C at 5°C / h, sintered at a constant temperature for 8 hours, and then coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com