Multilayer shuttle bus layer change safety device

A safety device and a technology for a shuttle car, which are applied in the field of layer-changing safety devices for multi-layer shuttle cars, can solve the problems of excessive power sources and jamming, and achieve the effects of reducing manufacturing cost, simplifying structure, and eliminating jamming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below through the accompanying drawings and examples, but the protection scope of the present invention is not limited to the content described.

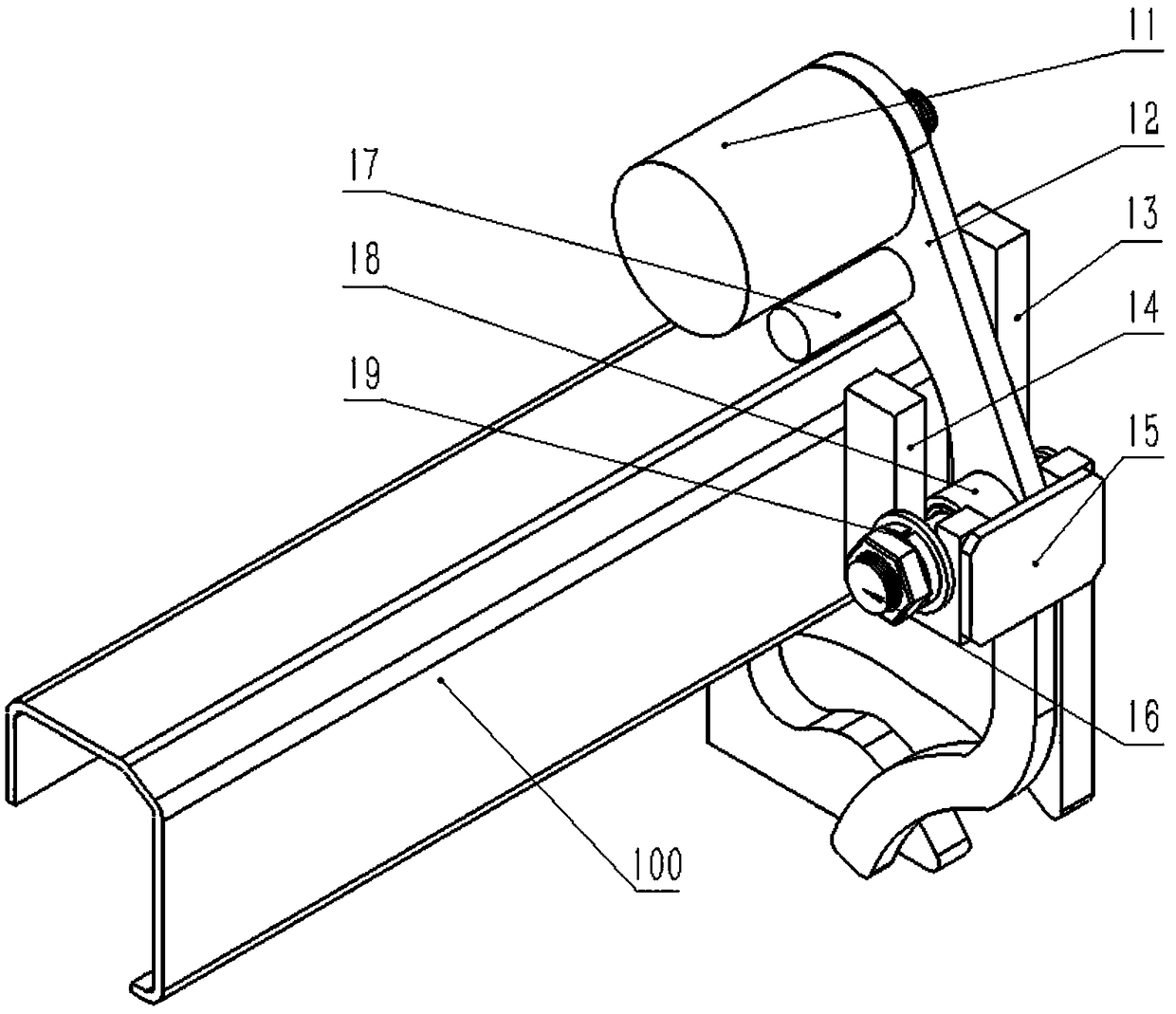

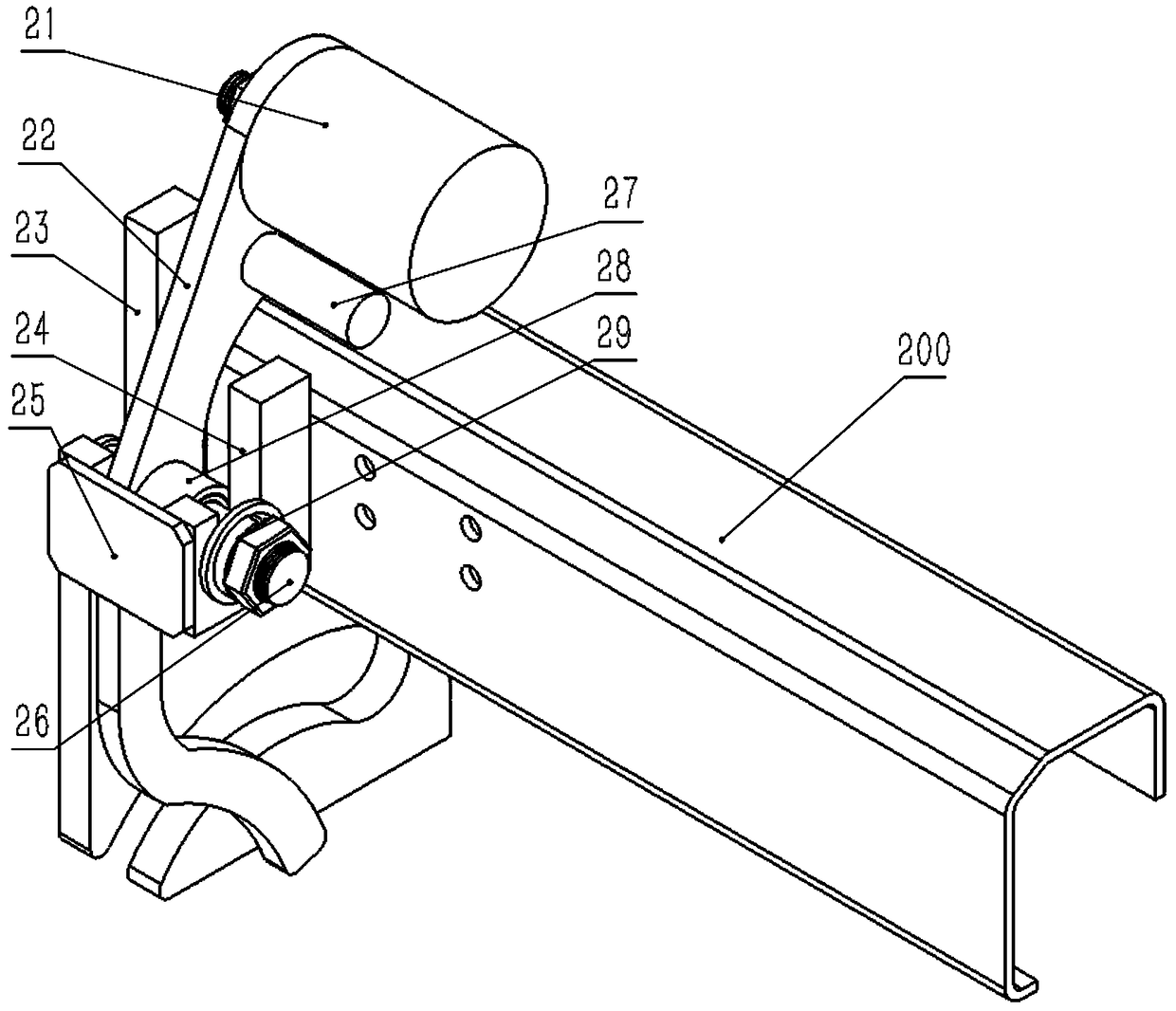

[0038] The following defines the space between the two rails of the shuttle vehicle running track 100 and the lifting platform track 200 as the inner side, and vice versa as the outer side.

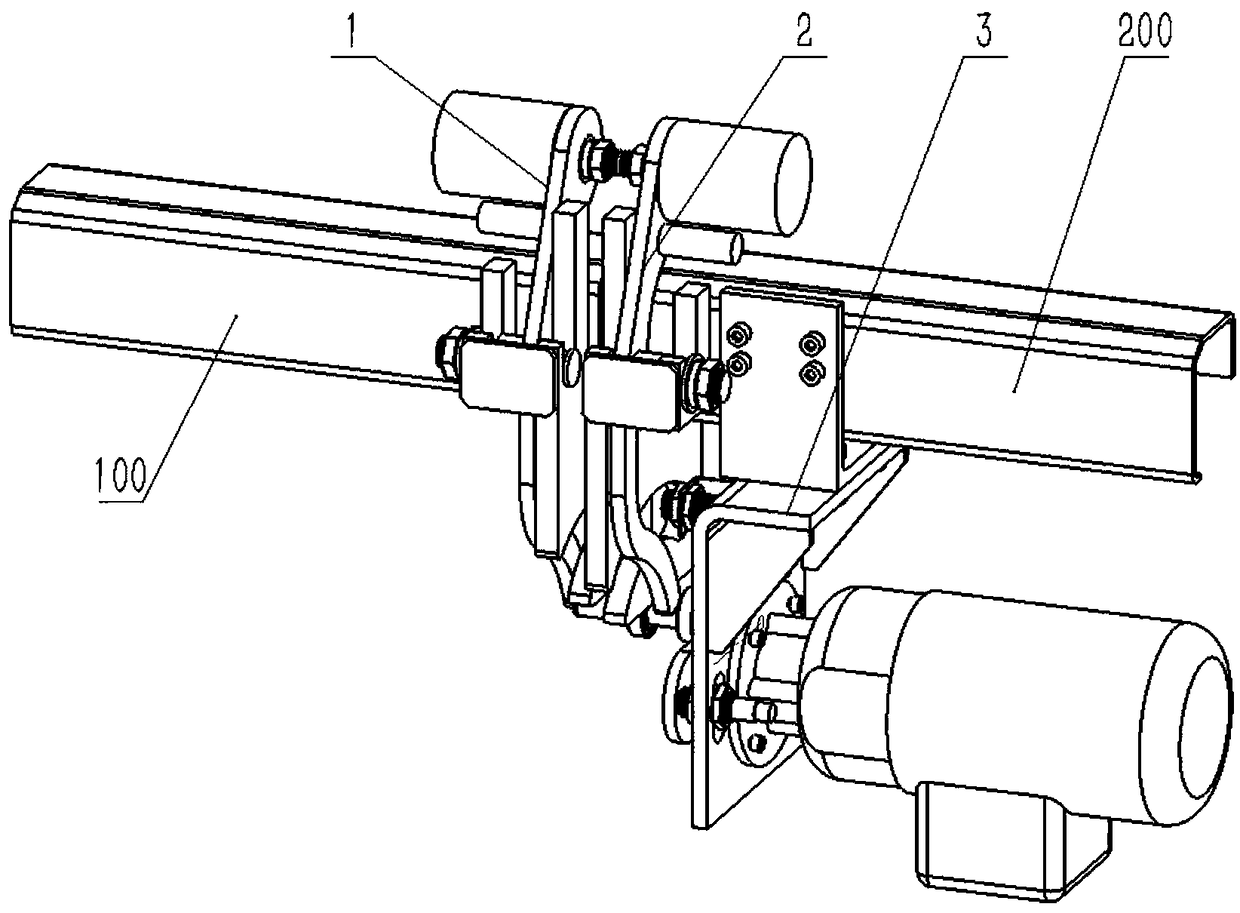

[0039] like Figure 1 to Figure 4 As shown, a safety device for changing floors of a multi-storey shuttle includes a shelf-side limiting assembly 1 , an elevator-side limiting assembly 2 and a swing arm device 3 . The shelf-side limit assembly 1 is installed on the outside of the end of the shuttle car running track 100 on each floor, and one set is arranged on each shelf. The hoist side limit assembly 2 is installed outside the end of the lift platform track 200, the swing arm device 3 is installed close to the elevator side limit assembly 2, and is suspended and installed under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com