Special-shaped hook-face steel structure glass top face conversion frame and implementation method thereof

A technology of special-shaped curved surface and conversion frame, which is applied in the direction of ceiling, building components, building structure, etc., can solve the problems of difficult support of steel structure and normal construction, etc., to ensure structural stability, construction quality and aesthetics, and construction. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

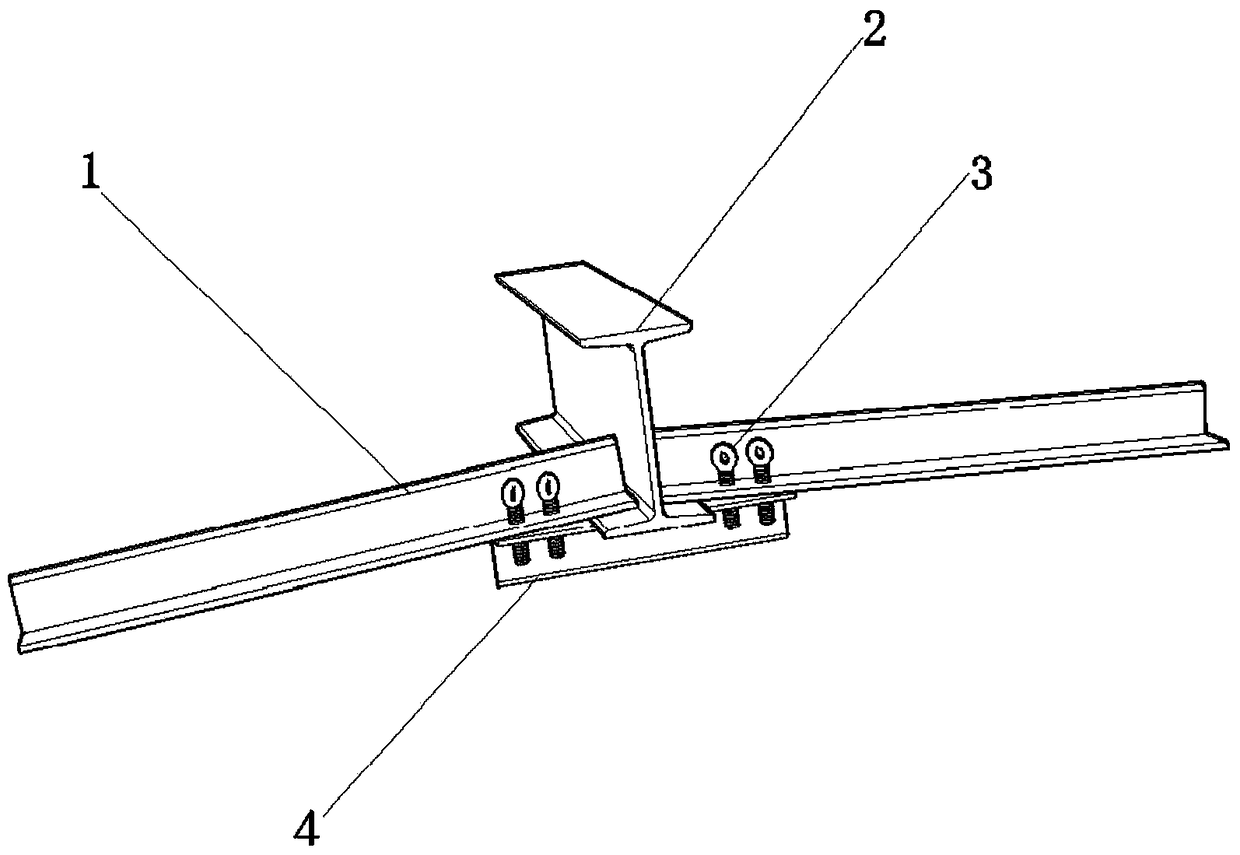

[0028] Such as figure 1 A special-shaped curved surface steel structure glass top conversion frame shown is supported under the supporting I-beam 2 of the glass top plate. The conversion frame includes a fixed angle steel 4 for the conversion frame. Both ends of the fixed angle steel 4 for the conversion frame are Eyebolts 3 are provided, and the fixed angle steel 4 of the conversion frame is connected with the horizontal load-bearing angle steel 1 of the conversion frame through the eyebolts 3. On the lower flange of steel 2.

[0029] Wherein, the length of the fixed angle steel 4 of the conversion frame is greater than the flange width of the supporting I-beam 2, the number of the eyebolts 3 on one side of the supporting I-beam 2 is 2, and the number of the eyebolts 3 on one side of the supporting I-beam 2 is two. The distance between the two eyebolts 3 on both sides and closest to the support I-beam 2 and the flange of the support I-beam 2 is 3cm, and the two adjacent eyeb...

Embodiment 2

[0039] All the other are identical with embodiment 1, difference is:

[0040] 1) The distance between the two eyebolts 3 that are located on both sides of the supporting I-beam 2 and closest to the supporting I-beam 2 and the flange of the supporting I-beam 2 is 5cm;

[0041] 2) In step 2, the length of the longitudinal load-bearing angle steel is designed according to the spacing of the transverse load-bearing angle steel 1 of the transfer frame, and its length is 1.5m.

Embodiment 3

[0043] All the other are identical with embodiment 1, difference is:

[0044] 1) The distance between the two eyebolts 3 located on both sides of the supporting I-beam 2 and closest to the supporting I-beam 2 and the flange of the supporting I-beam 2 is 1 cm;

[0045] 2) In step 2, the length of the longitudinal load-bearing angle steel is designed according to the spacing of the transverse load-bearing angle steel 1 of the transfer frame, and its length is 0.5m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap