Reinforced steel bar mechanical anchor docking connection joint structure and construction method thereof

A technology for connecting nodes and mechanical anchoring, applied in the direction of building structure, structural elements, building components, etc., can solve the problems of docking deviation, construction difficulty, poor force transmission performance, etc., to solve the problem of insufficient operating space, clear internal force transmission, and mechanization. high level effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

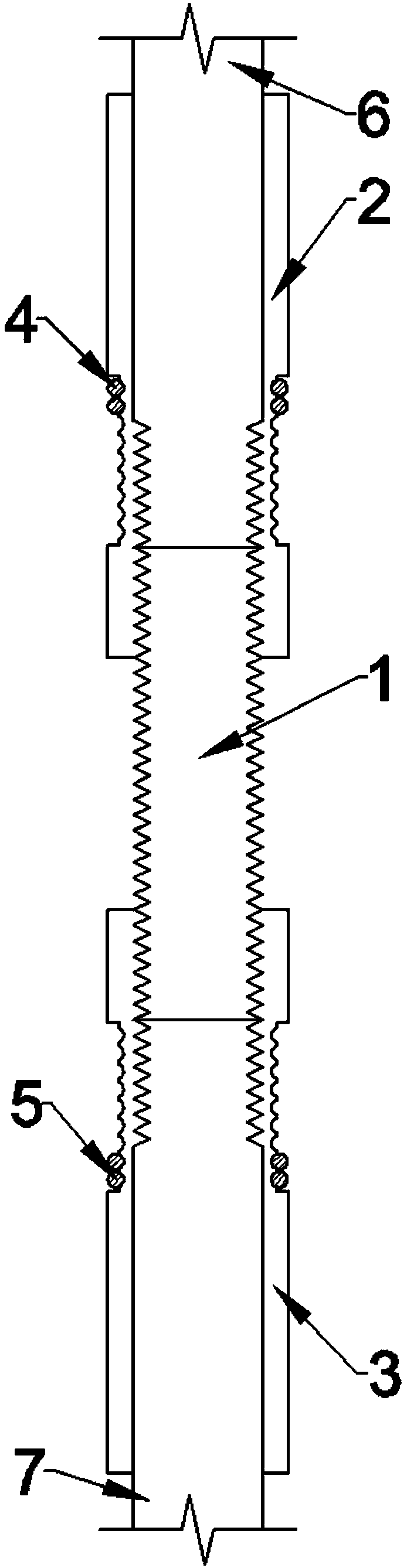

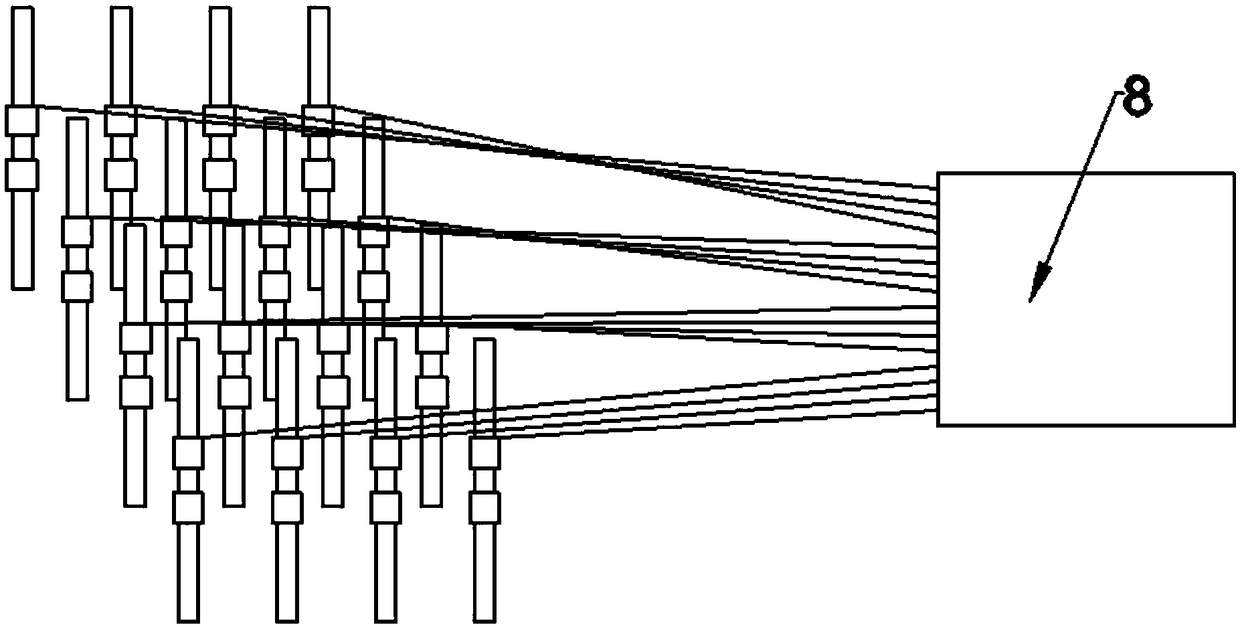

[0021] Embodiment: a kind of reinforced mechanical anchor butt joint connection node structure, such as figure 1 As shown, it includes an intermediate force transmission steel part 1, two upper and lower mechanical anchor members 2, 3, upper and lower steel bars 6, 7 and corresponding high-strength steel wires 4, 5 wound on the outer walls of the two mechanical anchor members 2, 3. The middle force transmission steel piece 1 is a cylindrical rigid member with flat ends and straight threads around the body. The upper and lower mechanical anchoring members 2 and 3 are hollow cylindrical rigid members, and the inner wall is provided with a straight thread matching the upper thread of the intermediate force transmission steel part 1 . Both ends of each intermediate force transmission rigid member 1 are simultaneously screwed into the upper and lower mechanical anchor members 2, 3 and anchored together. The outer ports of the two mechanical anchoring members 2 and 3 are the insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com