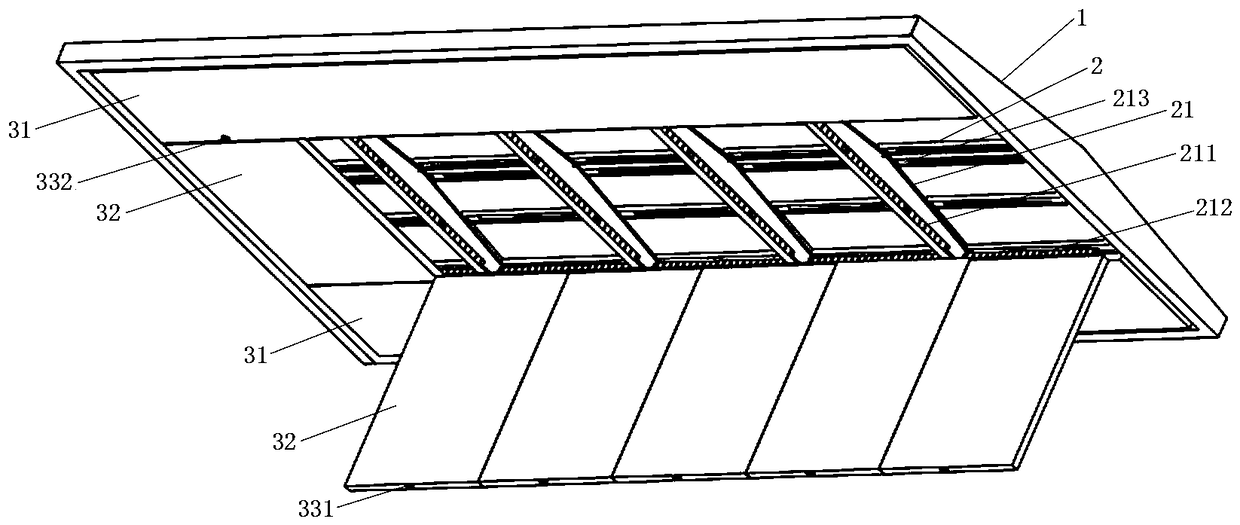

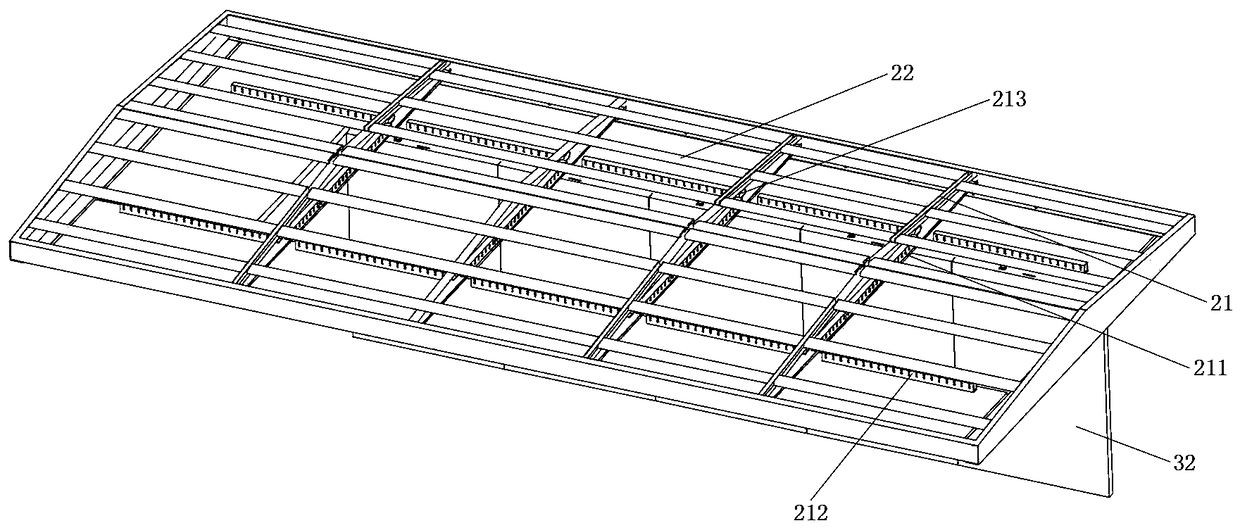

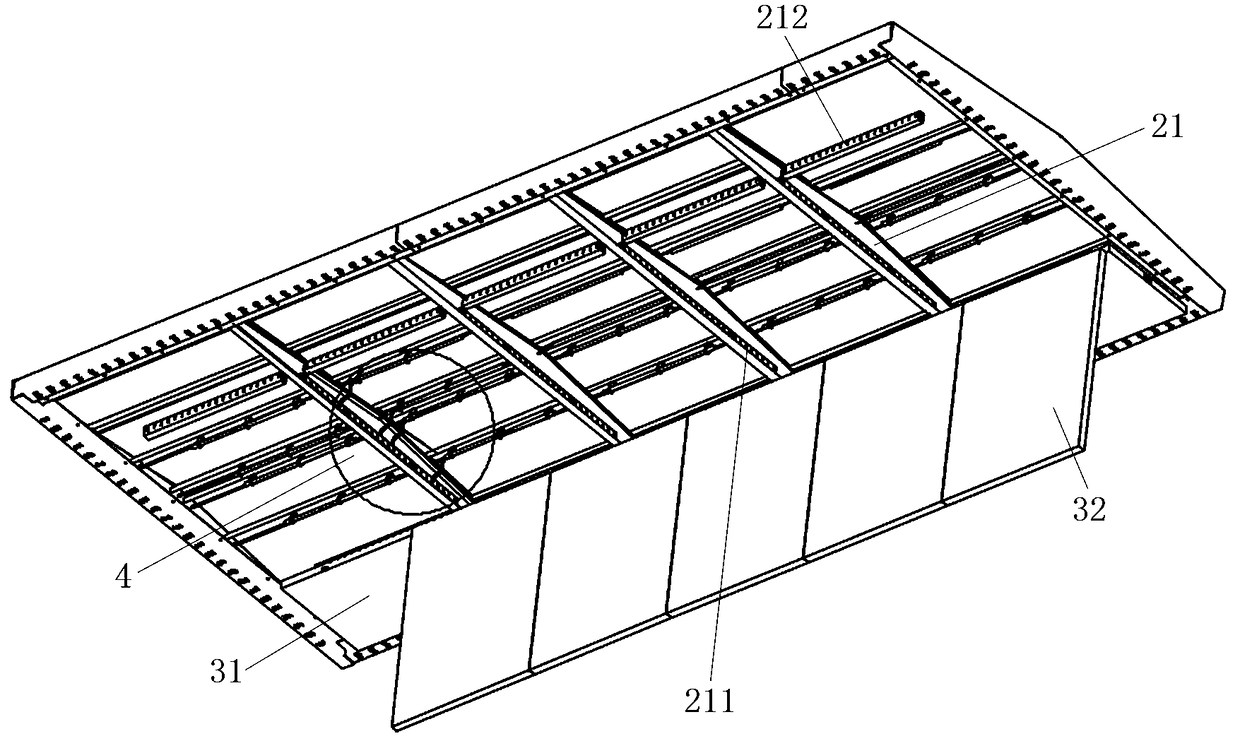

Prefabricated cabin and cabin roof thereof

A technology of prefabricated cabins and cabin roofs, applied in snow traps, small buildings, etc., can solve the problems of potential safety hazards, unsuitable substations, poor effects, etc., and achieve the effects of avoiding continuous accumulation, good ice melting effect, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0050] Embodiment 2: The difference from Embodiment 1 is that no horizontal and / or longitudinal wire grooves are provided, and the disadvantage is that the wiring is more chaotic, prone to entanglement, and unsafe.

Embodiment 3

[0051] Embodiment 3: The difference from Embodiment 1 is that there is one fixed insulation board, and the movable insulation board is hinged with the fixed insulation board through one side edge, or the number of fixed insulation boards is specifically set according to the structural arrangement inside the cabin.

Embodiment 4

[0052] Embodiment 4: The difference from Embodiment 1 is that when there are two fixed insulation boards, the movable insulation boards are also set to two, and the side edges of the two movable insulation boards that are away from each other are respectively hinged with the fixed insulation boards, The hinge shaft extends along the long side of the cabin roof, and the sides of the two movable insulation panels that are close to each other can be turned to open and close; Extending along the direction of the wide side of the cabin roof, the sides of the two movable insulation panels that are close to each other can be turned to open and close.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com