Mini liquid burner capable of reducing wall wetting effect and burning method thereof

A micro-liquid and burner technology, applied in the direction of combustion method, burner, combustion type, etc., can solve the problems of low fuel utilization rate, short mixture residence time, uneven combustion temperature distribution, etc., and achieve the effect of increasing residence time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

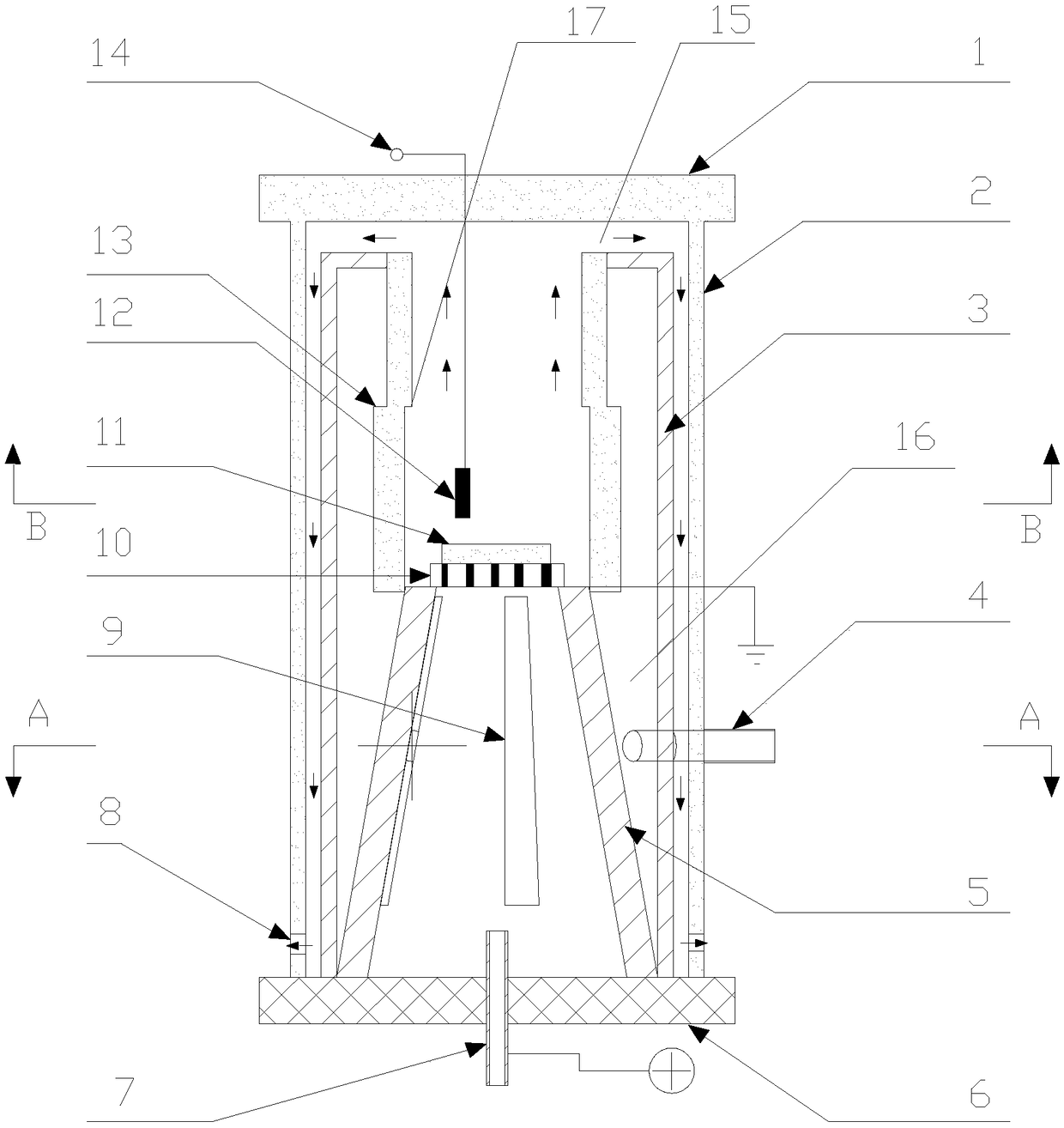

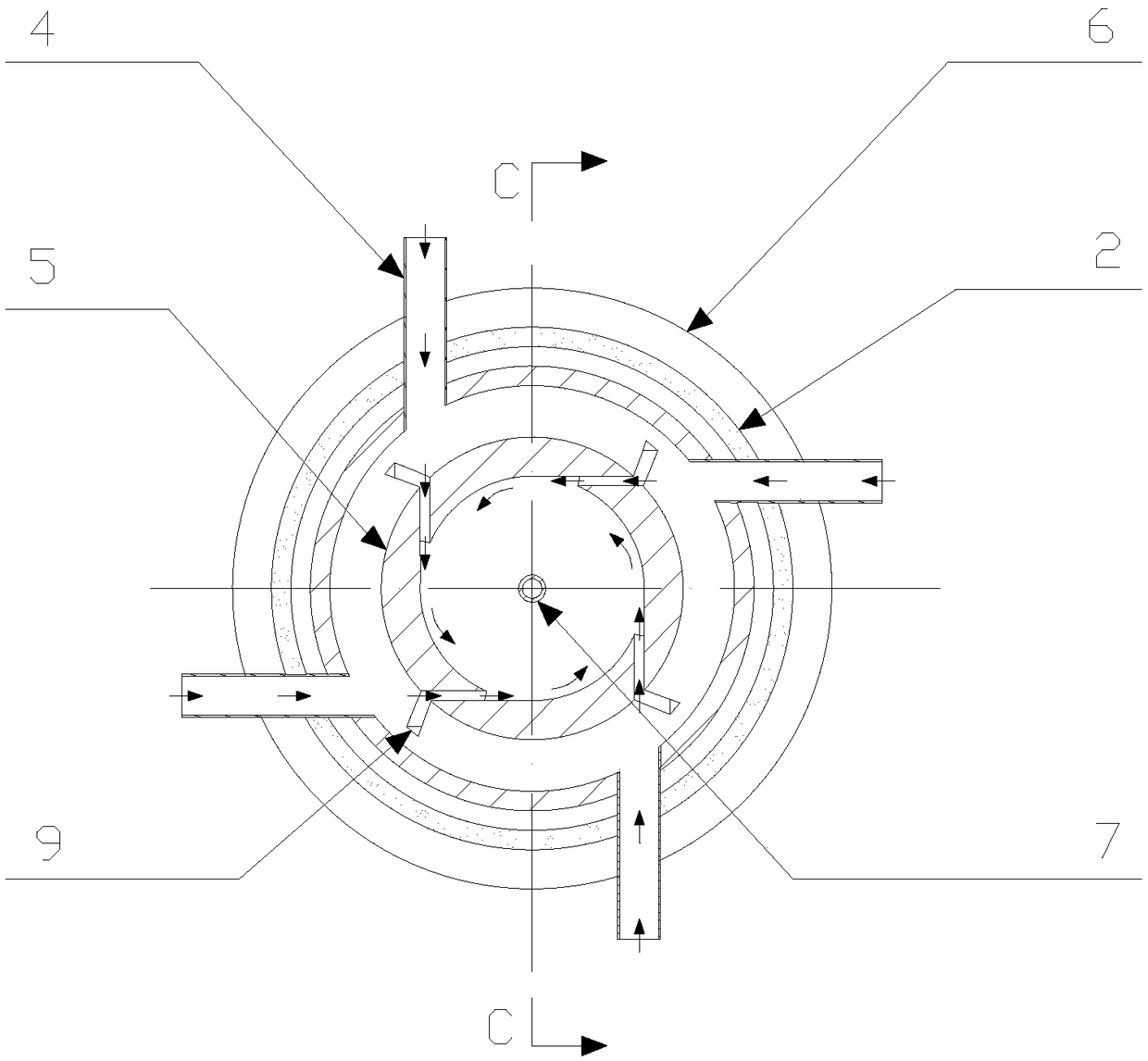

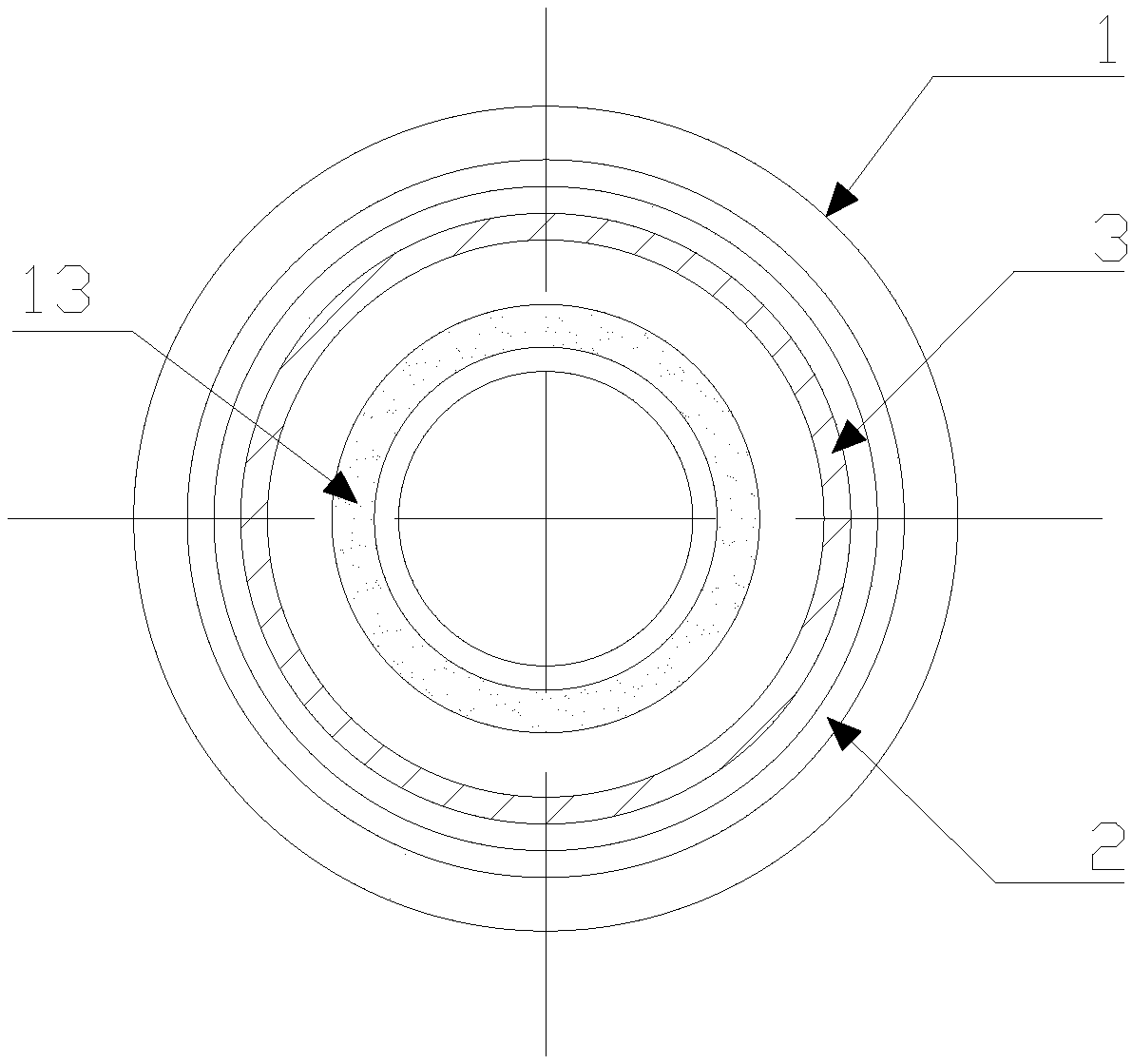

[0036] Such as Figure 1-5shown. The invention discloses a miniature liquid burner for reducing the wetted wall effect, which comprises an outer sleeve 2, an inner sleeve 3 and a combustion chamber 13 arranged at the inner upper part of the inner sleeve 3; the outer sleeve 2 and the inner sleeve 3 They are nested with each other, and their lower ends are sealed and fixed on the lower cover plate 6, and the upper end of the outer sleeve 2 is sealed by the upper cover plate 1; the fuel nozzle 7 is installed on the lower cover plate 6; the outer sleeve 2 and the inner sleeve 3 are connected to each other interval, and form the exhaust gas discharge channel; there is a gap 15 between the upper end of the inner sleeve 3 and the upper cover plate 1, and the upper port of the inner sleeve 3 is sealed with the outer edge of the combustion chamber 13; the exhaust gas after combustion in the combustion chamber 13 , sequentially discharged from the gap 15 at the upper end of the inner s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap