Space humidity control method for floor board cold supply composite displacement ventilation system

A displacement ventilation and humidity control technology, applied in ventilation system, space heating and ventilation control input, space heating and ventilation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

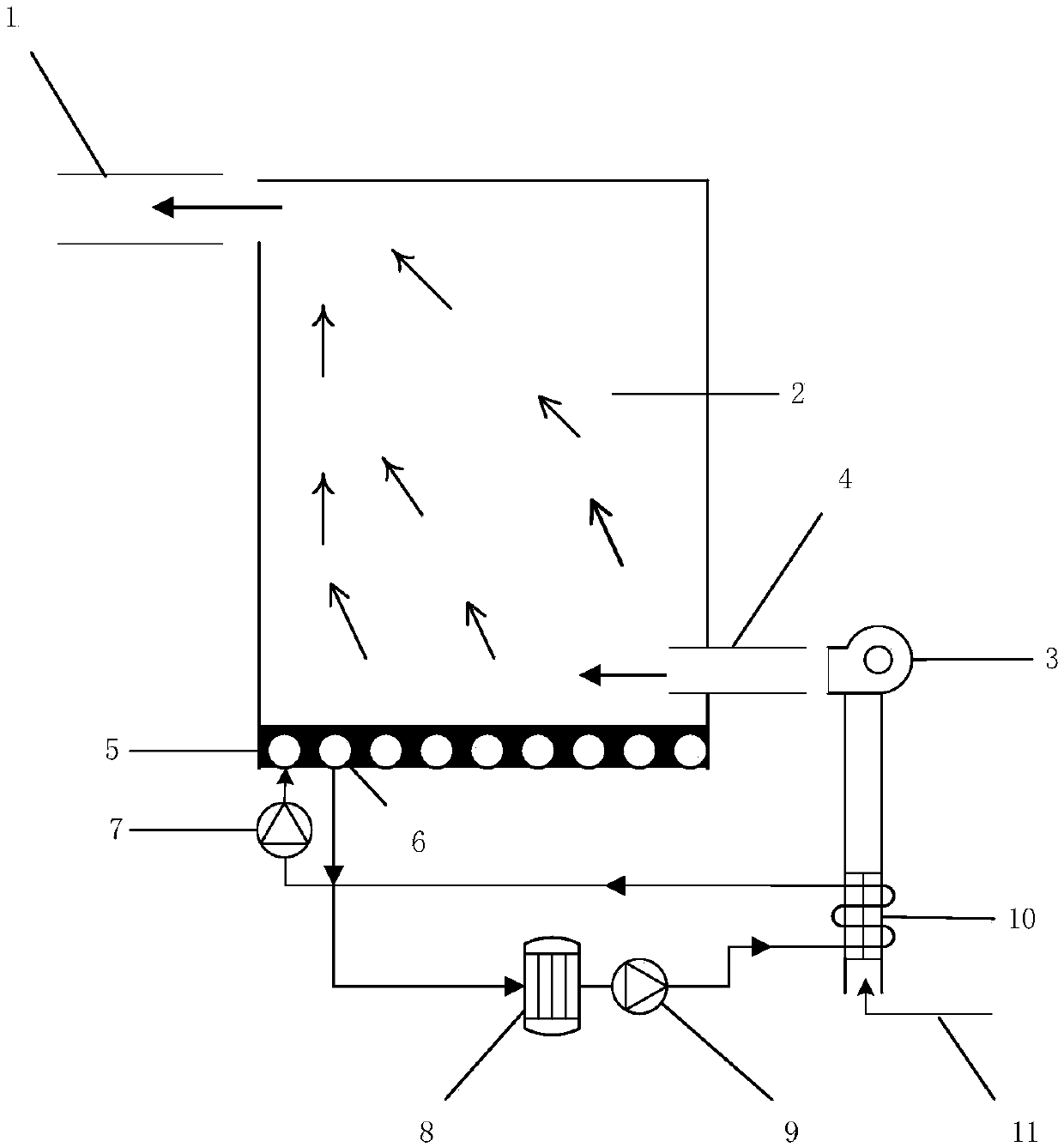

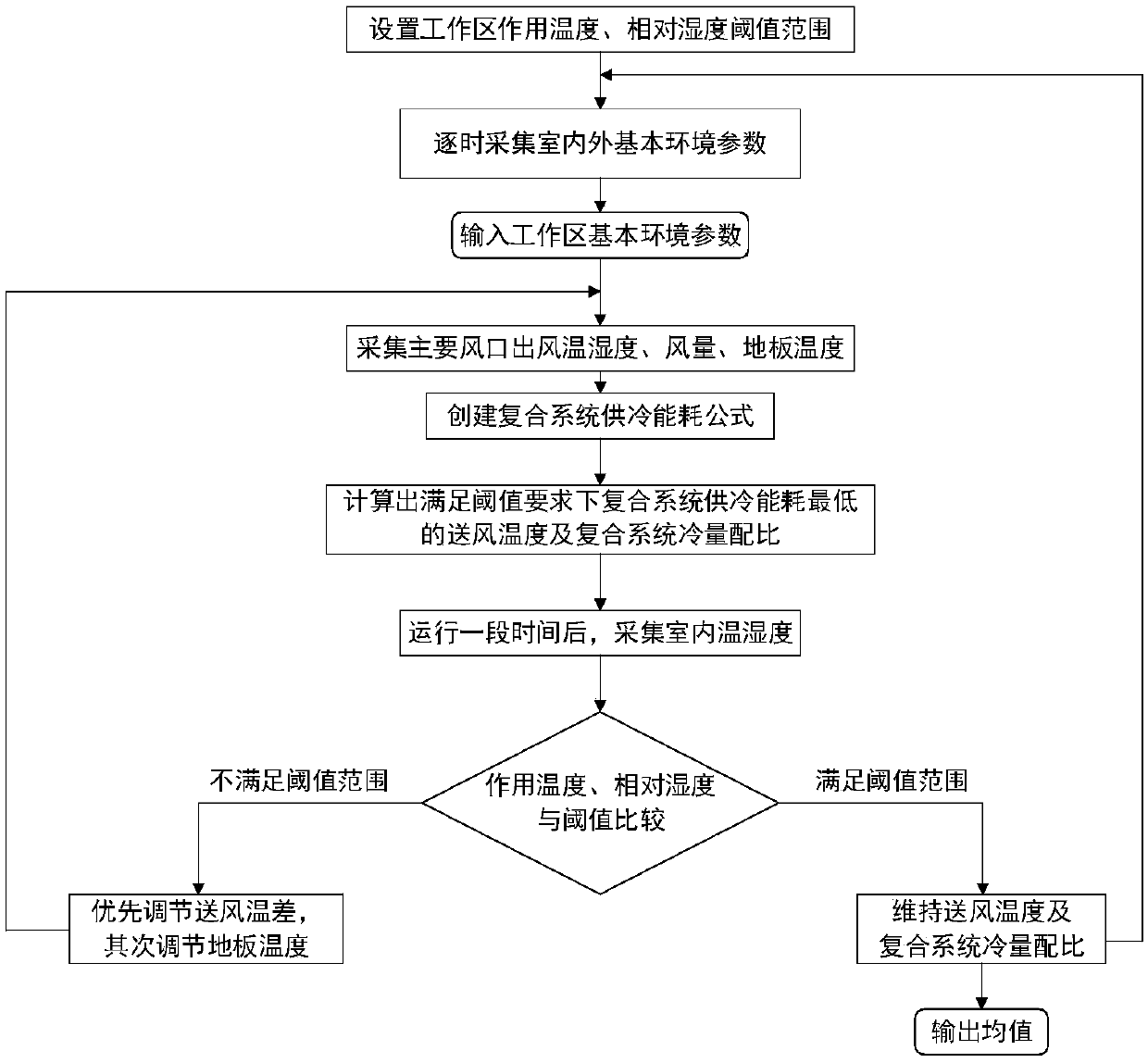

[0034] This embodiment provides a space humidity control method for a floor cooling composite displacement ventilation system, such as figure 1 shown, including:

[0035] (1) Set the temperature threshold range of the working area to [t od ,t ou ], the relative humidity threshold range is [Ф d ,Ф u ].

[0036] Among them, according to the ISO standard, the working temperature threshold range is 20° C. to 26° C., and the relative humidity threshold range is 40% to 65%.

[0037] (2) Collect the basic environmental parameters of the work area in different time periods, including the temperature of the work area t a , relative humidity in the working area Supply air relative humidity mean radiant temperature t r , the number of personnel n τ .

[0038] Specifically, from 8:00 a.m. to 18:00 p.m., with an interval of 1 hour for each collection.

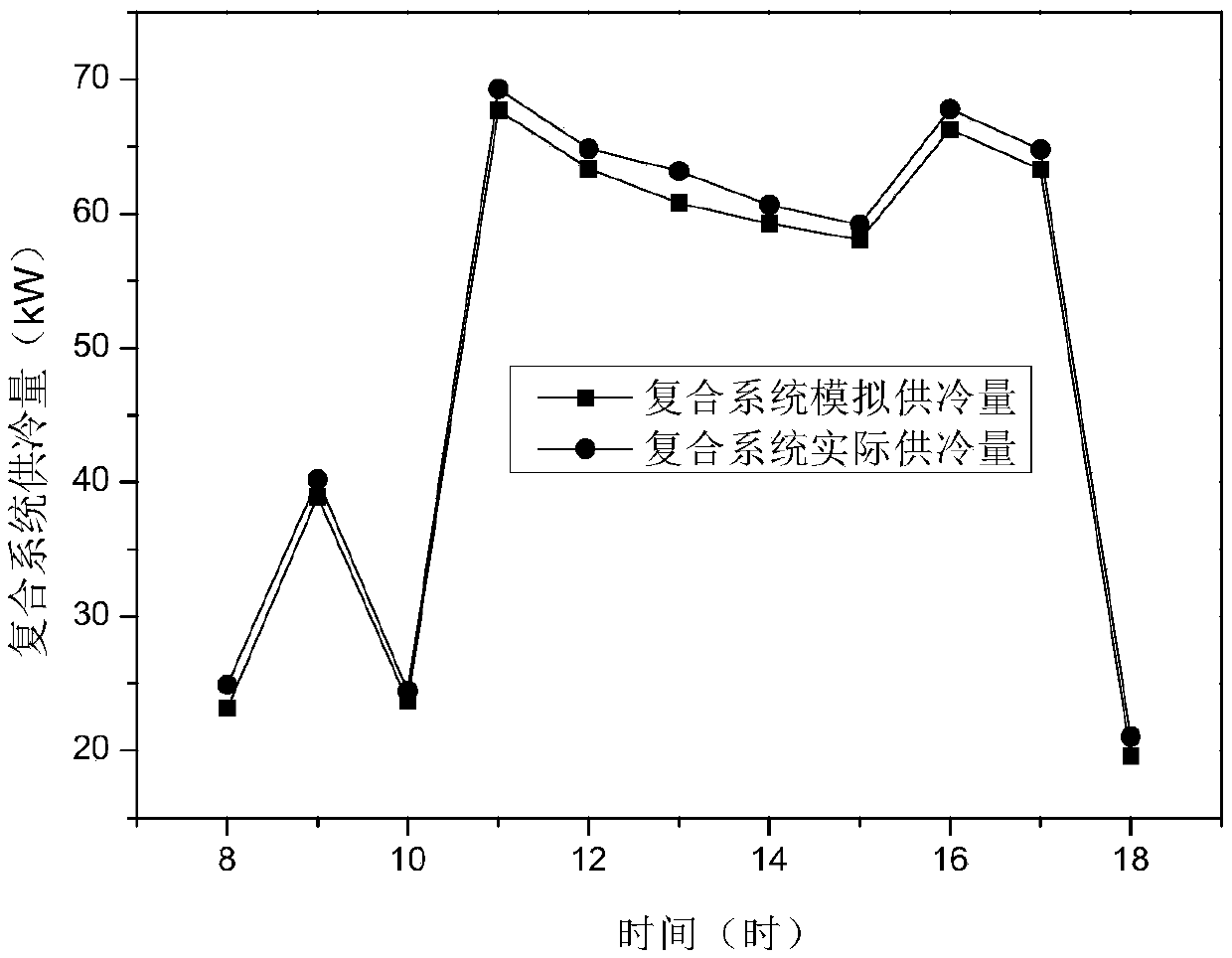

[0039](3) Taking the lowest cooling energy consumption of the composite displacement ventilation system as the objective func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com