DPF carbon loading computing method

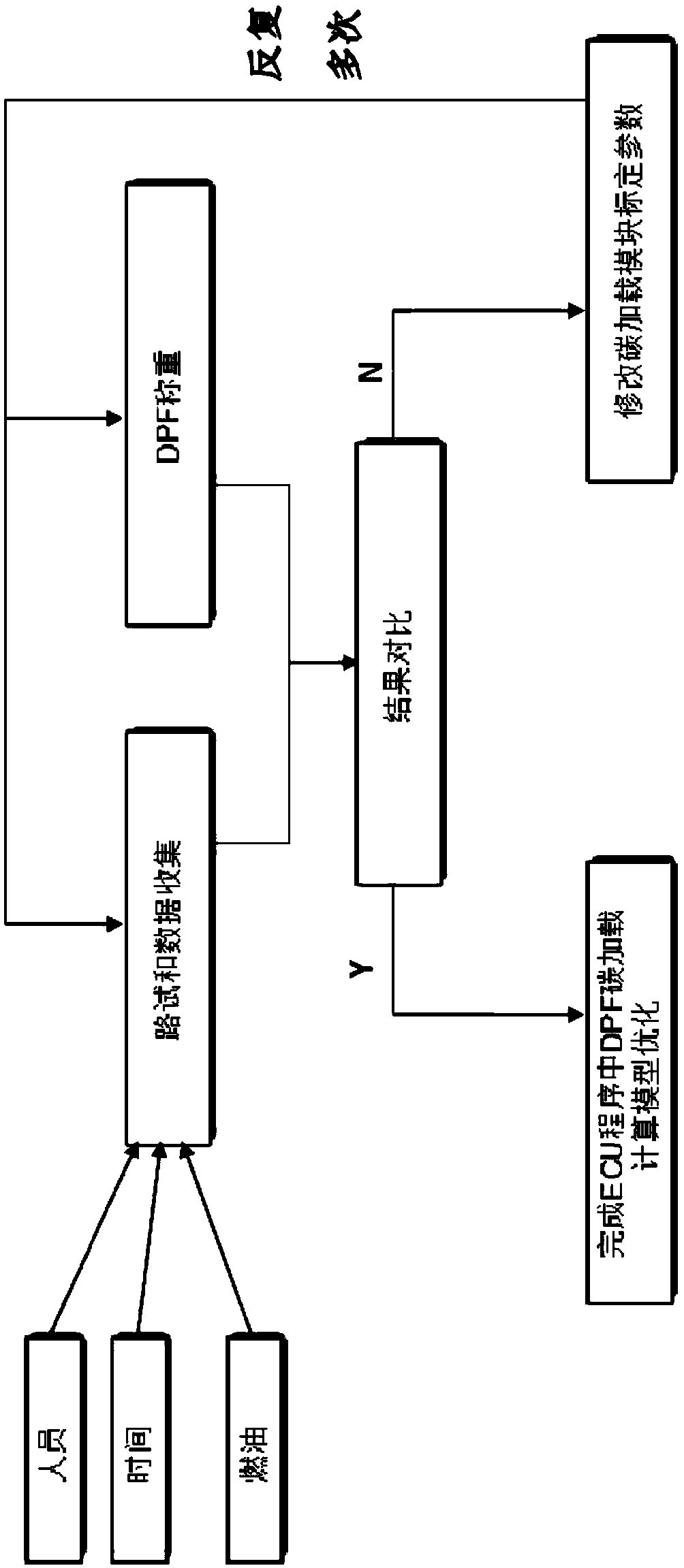

A calculation method, DPF technology, applied in the direction of calculation, design optimization/simulation, special data processing applications, etc., can solve the problems of large personnel, time and cost, frequent DPF regeneration, high actual fuel consumption, etc., to save road test time, reduce Effects of R&D and Calibration Costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

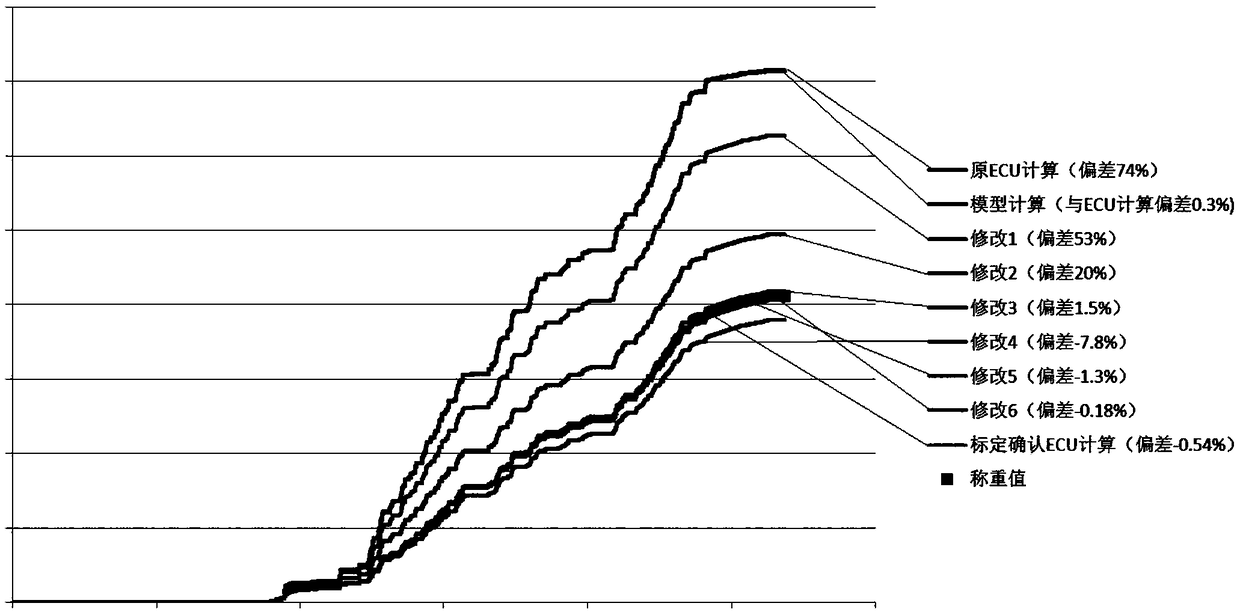

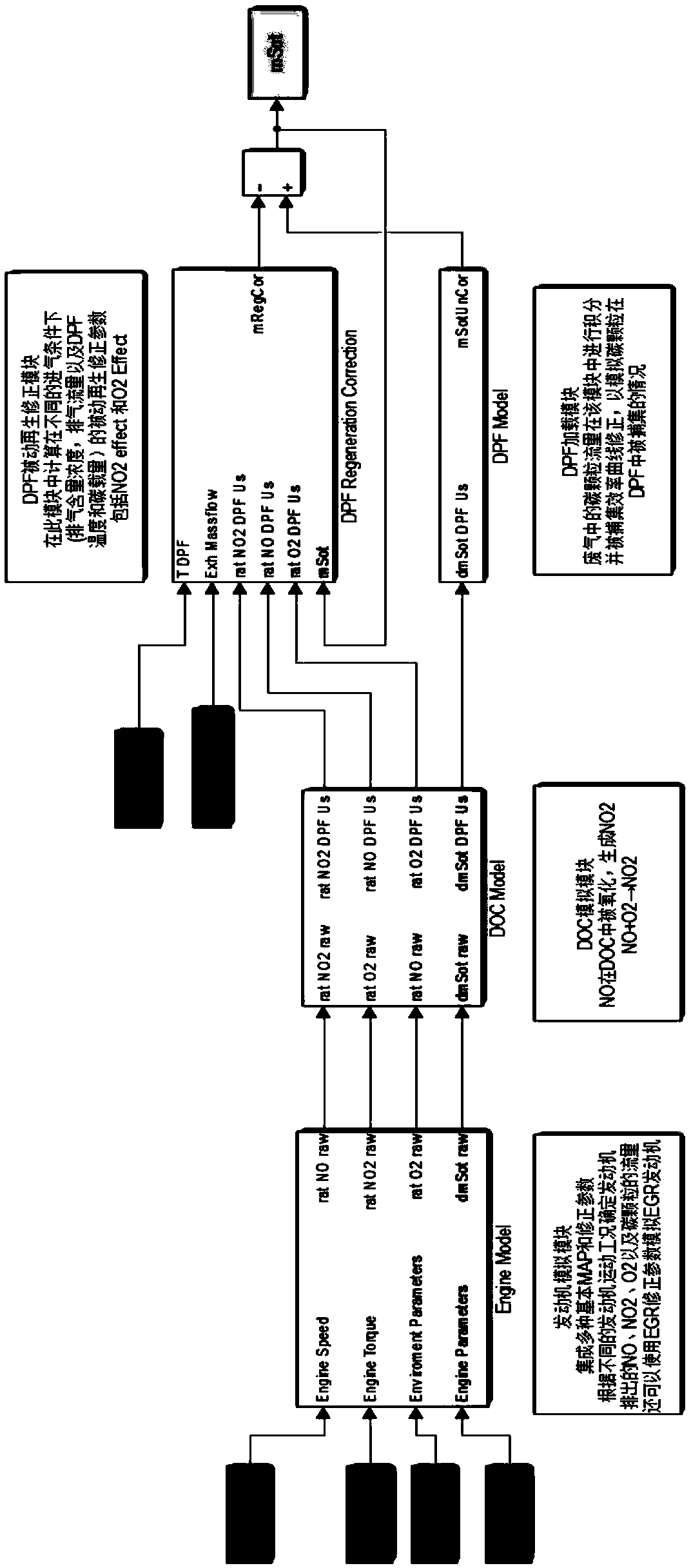

[0042] see Figure 1 to Figure 6 , the present invention provides a DPF carbon loading calculation method, the carbon particles are mainly produced by the incomplete combustion of diesel oil in the combustion process of the engine, and then trapped in the DPF and gathered in the DPF, this process is collectively referred to as the carbon loading process of the DPF . The rate of this process, as well as the carbon load, is influenced by the NO in the exhaust 2 , O 2 As well as the influence of DPF temperature and exhaust gas flow, this patent model is built to simulate this process.

[0043] m Sot =∫(dm Sot -dm Rgn )dt Formula 1;

[0044] dm Rgn = m Sot *eff NO2 *eff O2 *eff T-m Formula 2;

[0045] The DPF model is built based on formula 1 and formula 2, where dm Sot is the output carbon flow of the engine module, dm Rgn NO for carbon in DPF 2 and O 2 The specific value of passive regeneration flow is calculated by formula 2. NO in formula 2 2 Effect on carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com