Garlic clove separating and peeling machine

A peeling machine and splitting technology, applied in the field of machinery, can solve the problems of high damage rate of garlic cloves, low efficiency of continuous operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

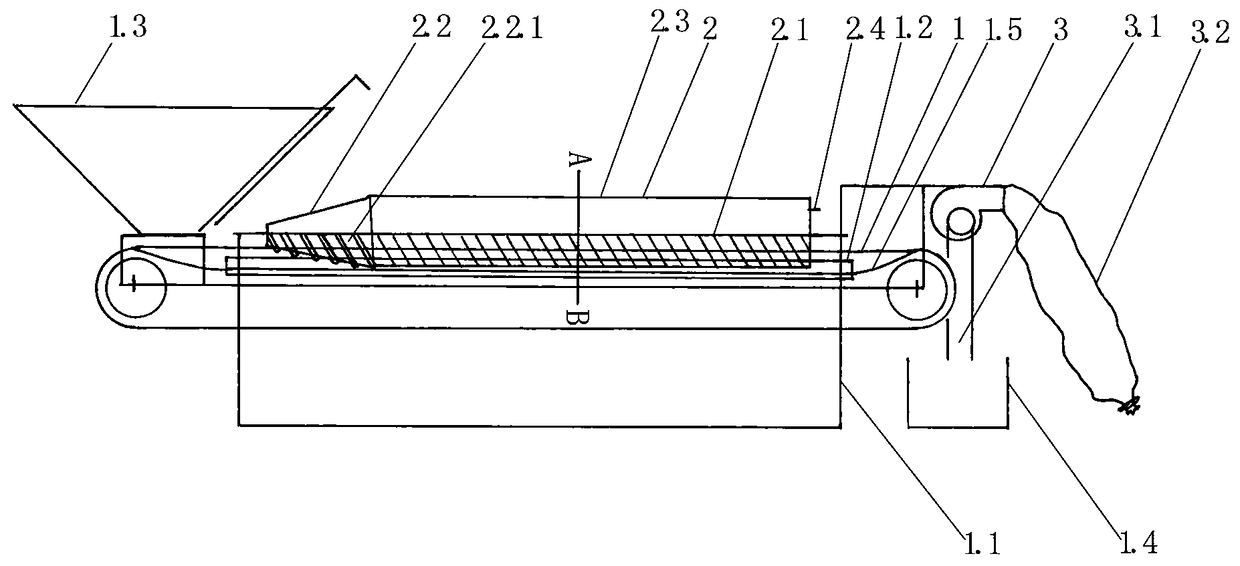

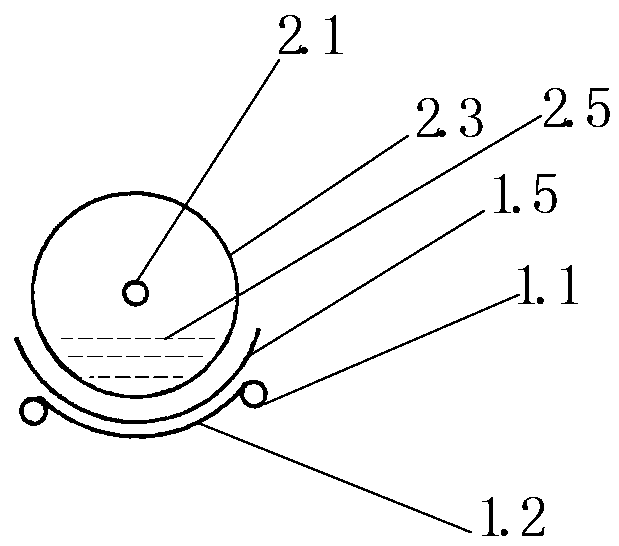

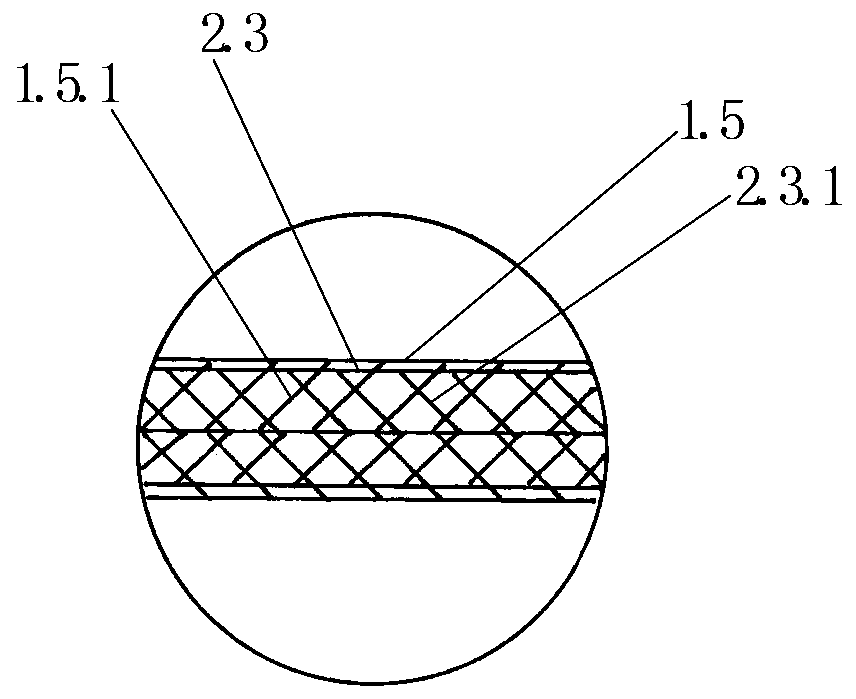

[0011] exist figure 1 , 2 , 3, a kind of garlic splitting and peeling machine provided by the present invention, it is made of three parts of the long air bag of belt shaft, belt conveyor and exhaust fan, it is characterized in that: in 6--12 meter long belt A long air bag with a shaft is fixed on the conveyor (1), and there is an exhaust fan (3) at the end of the belt conveyor (1); under the belt of the belt conveyor (1) is a "U"-shaped chute ( 1.2); the belt surface of the belt conveyor (1) has convex and concave stripes with a "V"-shaped sawtooth tooth table forward and a depth of 2 mm; the head end of the long airbag with shaft is a solid cone Pointed, solid cone-shaped lower surface with a 50--20 mm wide, 20--10 mm deep inverted "V"-shaped large groove (2.2.1), the cylindrical air bag (2.3) behind it The lower surface has an inverted "V"-shaped saw-toothed tooth table and a concave-convex stripe with a depth of 2 mm that is opposite to the upper tooth table of the belt;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com