Spiral-wound membrane element

A roll-type membrane and element technology, which is applied in the field of membrane elements, can solve the problems of restricting the permeate flux of membrane elements, and achieve the effects of improving the permeate flux, prolonging the service life, and being easy to popularize and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

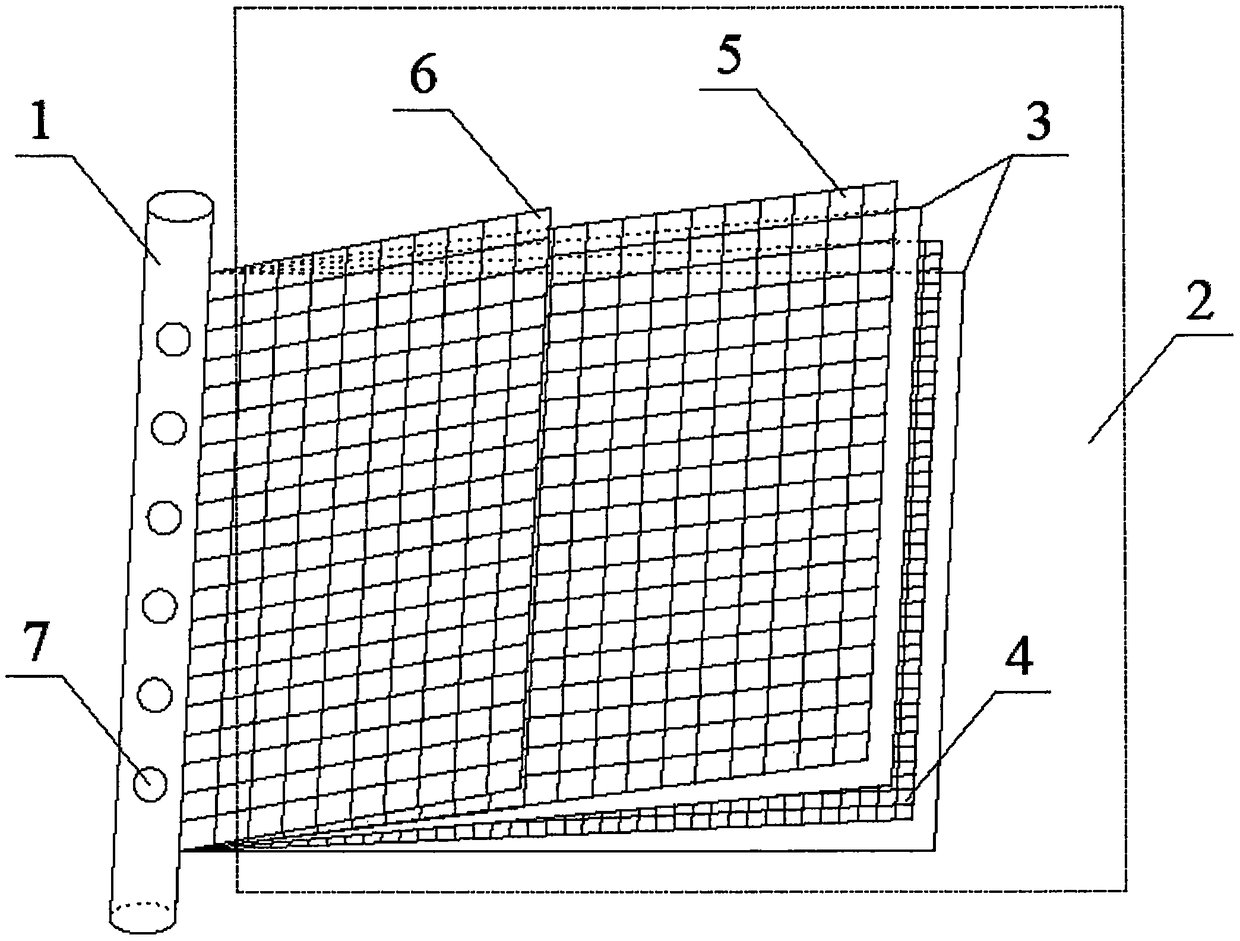

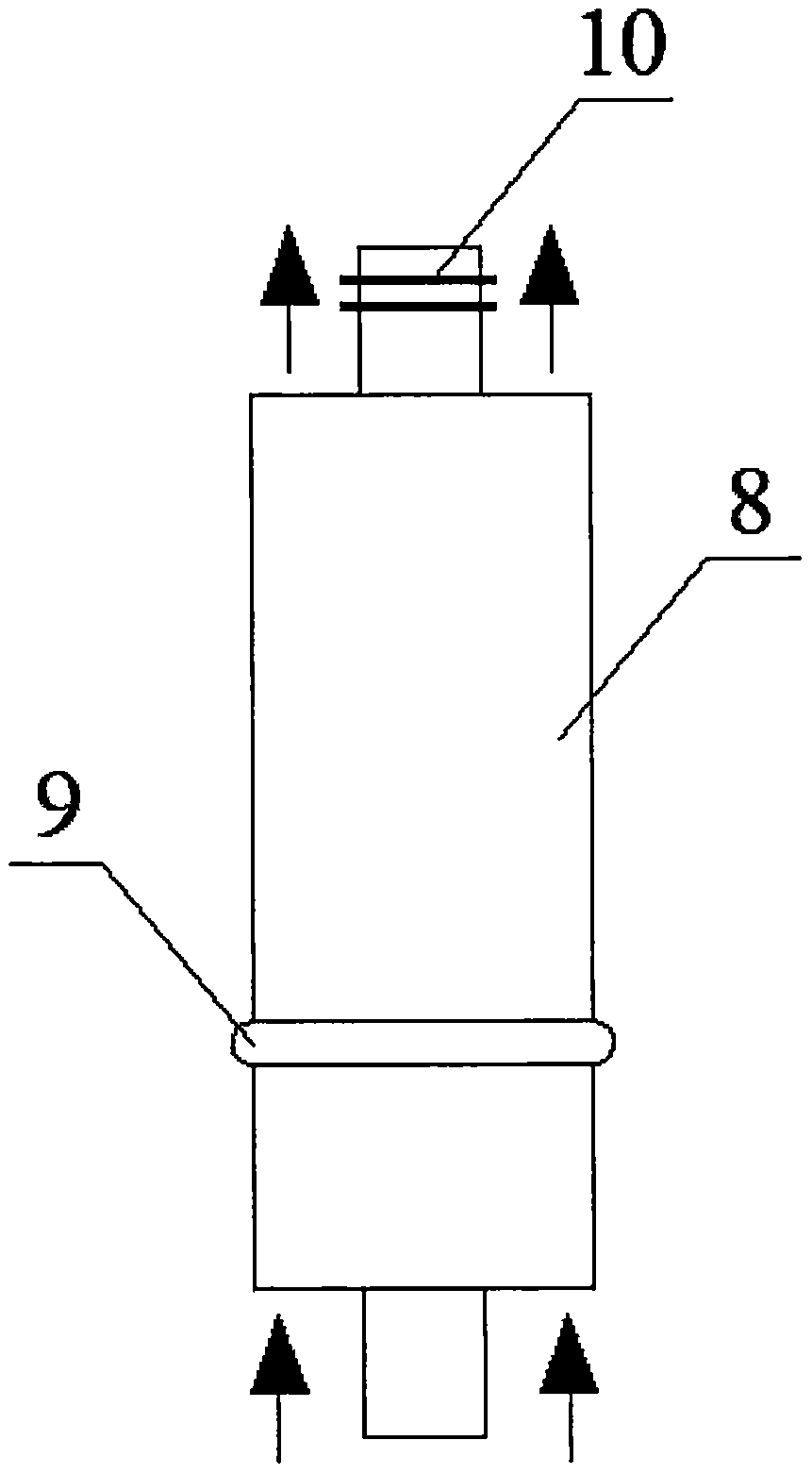

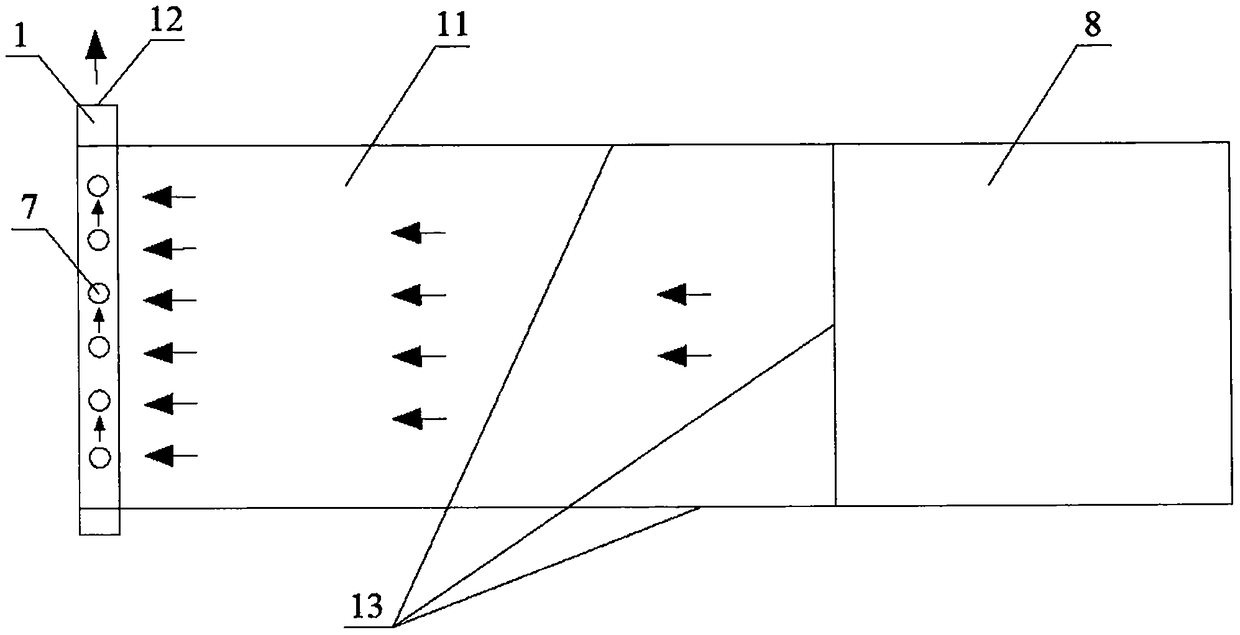

[0023] Such as Figure 1 to Figure 4 As shown, this embodiment provides a roll-type membrane element, including a central water production pipe 1, and at least one set of water purification membranes 2 wound on the central water production pipe; the water purification membranes 2 include a production Water diversion net 5, two separation membranes 3 and a raw water diversion net 4, the two separation diaphragms 3 are self-made membranes with a length of 1m and a width of 0.32m folded in half; the inside of the two separation diaphragms 3 Between the surfaces is a raw water flow channel 14, and between the outer surfaces of the two separation membranes 3 is a water production flow channel 11; the raw water diversion net 4 is arranged in the raw water flow channel 14, with a thickness of 0.5 mm, a length of 51 cm, and a width of is 0.32m; the water production diversion net 5 is arranged in the water production flow channel 11; the central water production pipe 1 is provided with...

Embodiment 2

[0029] See Figure 5 , this embodiment is basically the same as Embodiment 1, the difference is that the length of the new water-producing diversion net 5 in this embodiment is four-fifths of the length of the original water diversion net 4, and the width is 4 / 5 of the original water diversion net 4. Half of the width of the flow net 4, the newly added water production diversion net 5 is placed in the middle of the central water production pipe 1, and the side is connected with the central water production pipe 1.

[0030] The test conditions of the coiled membrane element of the present embodiment are as follows:

[0031] The membrane element conventionally rolled by the above-mentioned water purification membrane group was tested under the conditions of 0.2Mpa, 200ppm sodium chloride solution, and 35% recovery rate. The efficiency is 95%; after the membrane element has been improved and implemented in this scheme, it is tested under the same conditions, and the purified wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com