Transfer trolley for transporting minerals

A technology of trolleys and minerals, applied in the field of turnover trolleys, can solve the problems of high labor intensity of the staff, and achieve the effects of simple structure, improved unloading efficiency, and convenient unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

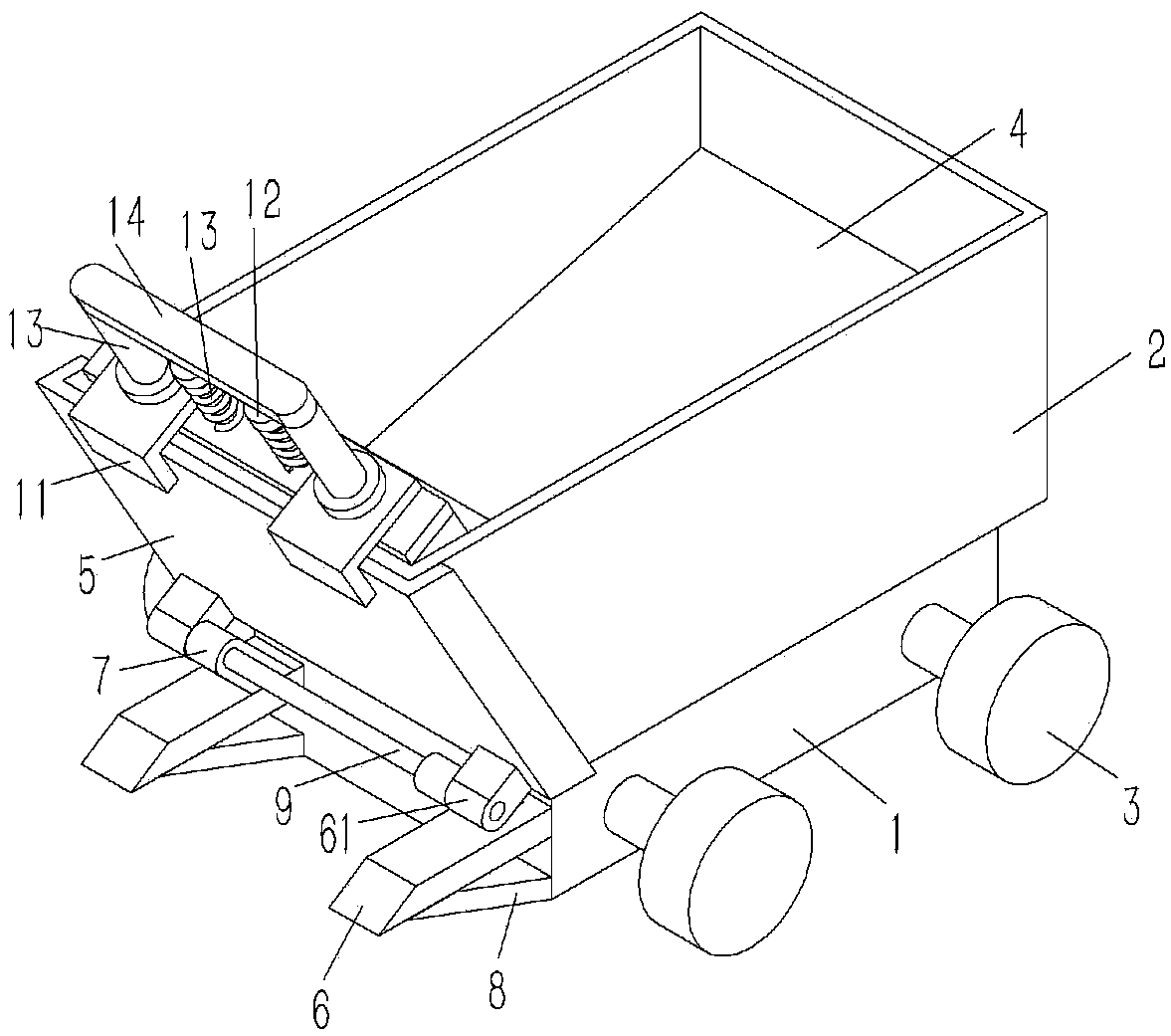

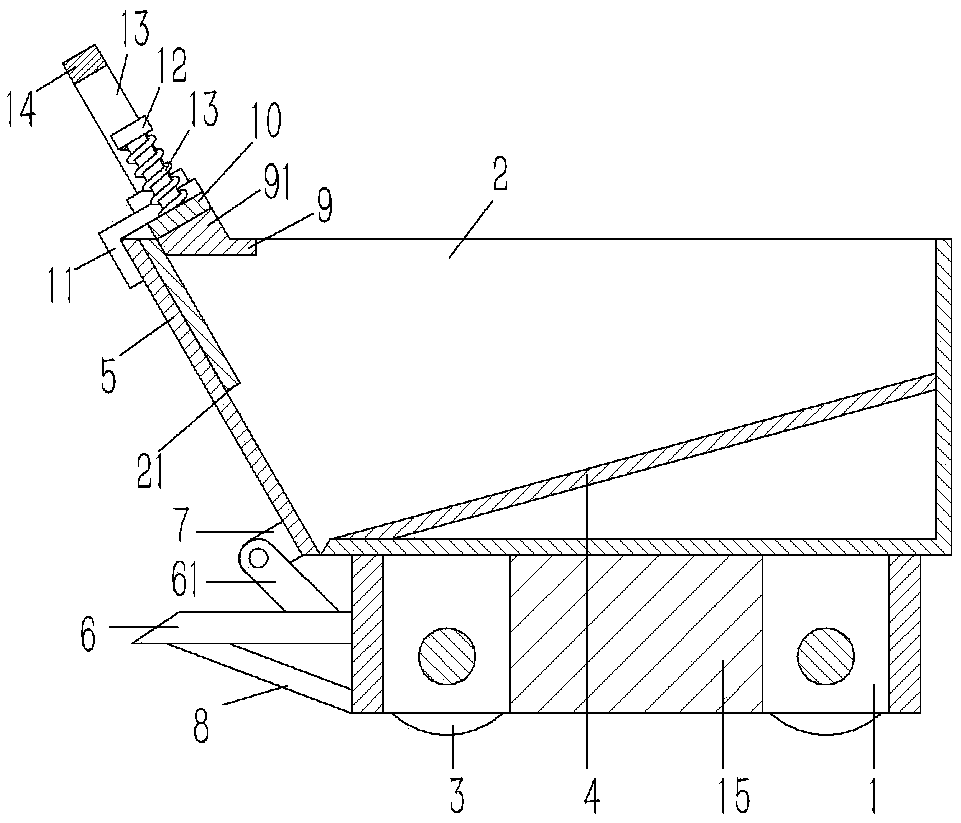

[0016] Example: see figure 1 , 2 As shown, a turnaround trolley for transporting minerals includes a rectangular bottom frame 1 on which a number of wheels 3 are fixed. The bottom frame 1 is fixed on the lower end surface of the car body 2. The lower end of the inclined side wall of the vehicle bucket 2 is formed with a discharge opening 21, the discharge opening 21 of the vehicle bucket 2 is covered with a cover plate 5, and several hinged supports 7 are fixed on the lower end of the cover plate 5, and the cover plate 5. A horizontal support rod 6 is formed on the side wall of the bottom frame 1 on the lower side, and a lug 61 is formed on the support rod 6. The lug 61 is hinged on the hinge support 7 through the hinge shaft 9. The inside of the vehicle bucket 2 Fix the inclined deflector 4; the upper end of the cover plate 5 is provided with several L-shaped buckles 11, the buckles 11 are fixed on both sides of the strip-shaped mounting plate 10, and the lower side of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com