Automatic positioning and uniform slitting method and equipment for bamboo chips

An automatic positioning and uniform technology, which is applied in the direction of mechanical equipment, vibration suppression adjustment, forming/shaping machine, etc., can solve the problems of difficult operation of adjusting the spacing, rough and uneven slice surface, high degree of device wear, and achieve the reduction of rough slice surface and slice Uniform, wear-free and chatter-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

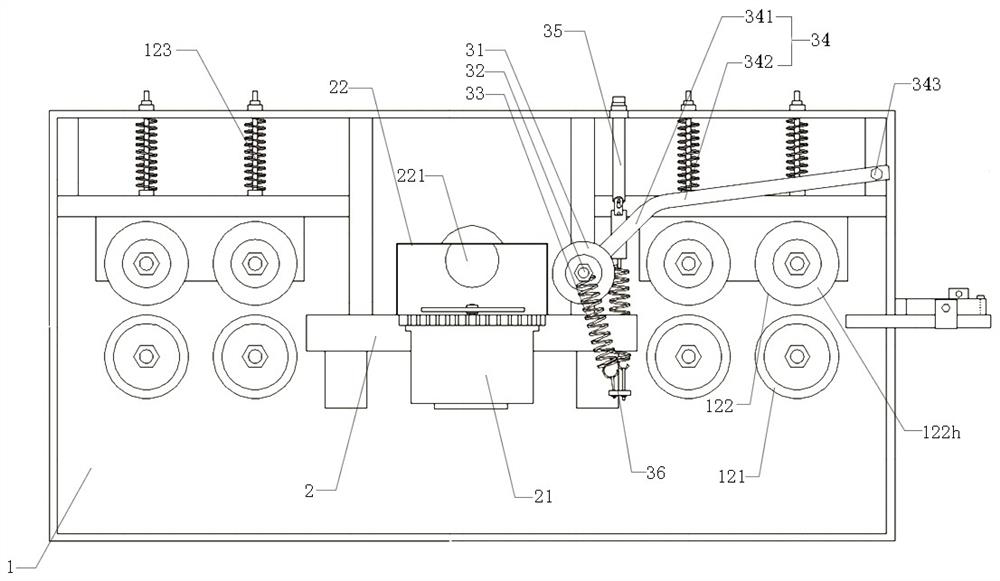

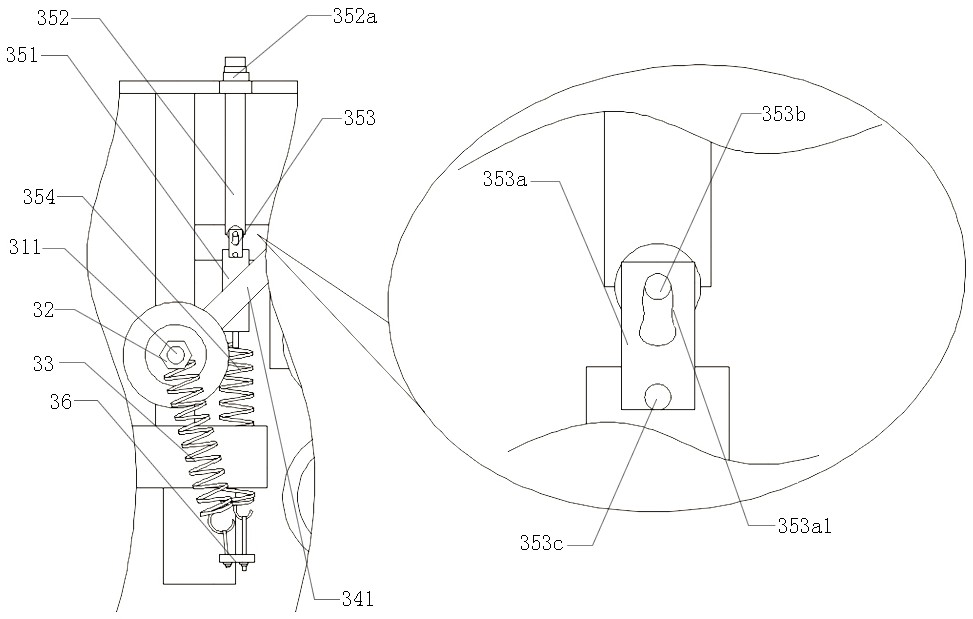

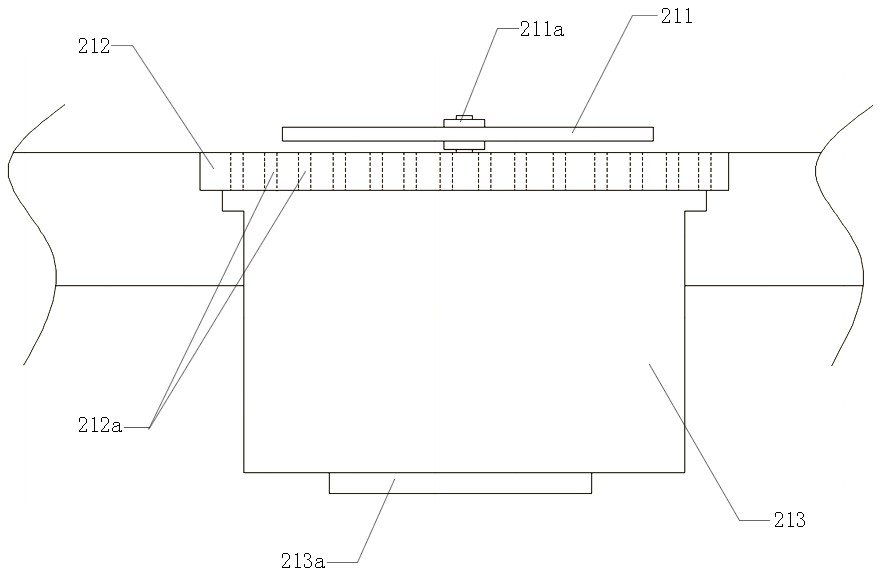

[0041] Such as figure 1 , 7 As shown, the components of the main body 1 of the slitting equipment: (1) feeding unit, (2) input unit, (3) positioning unit, (4) slitting unit, (5) output unit. In this embodiment, the input unit and the output unit are each composed of two sets of driving rollers. Each transmission roller is all connected with a transmission gear, so the input unit has two sets of first transmission gear sets 52, the output unit has two sets of second transmission gear sets 53, and the lower end of the first transmission gear set 52 is equipped with a first motor 50 A first driving gear 51 is installed on the driving rod of the first motor 50, and the first driving gear 51 is connected with the first transmission gear set 52 and the second transmission gear set 53 through a transmission belt 54. The cutting knife in the cutting unit is connected with the second drive gear 61 driven by the second motor 60, and the second drive gear can be connected with the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com