Circular cooler and unit static sealing device thereof

A technology of static sealing device and annular cooler, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of easy damage to the lower flat plate 112 of the sealing rubber trolley, damage to the sealing rubber and the trolley body, etc. Complete unloading effect, lower maintenance cost, lower maintenance frequency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

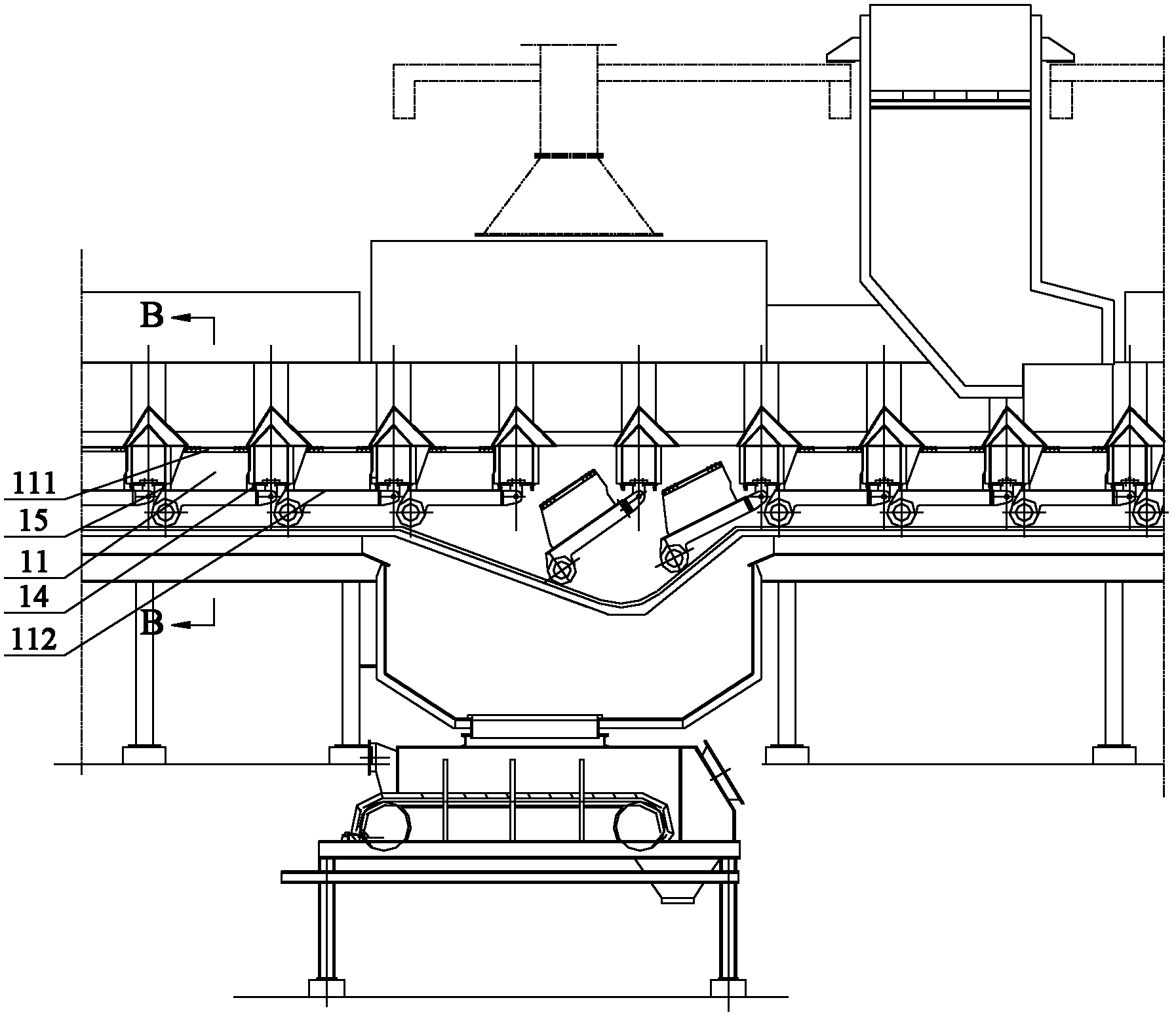

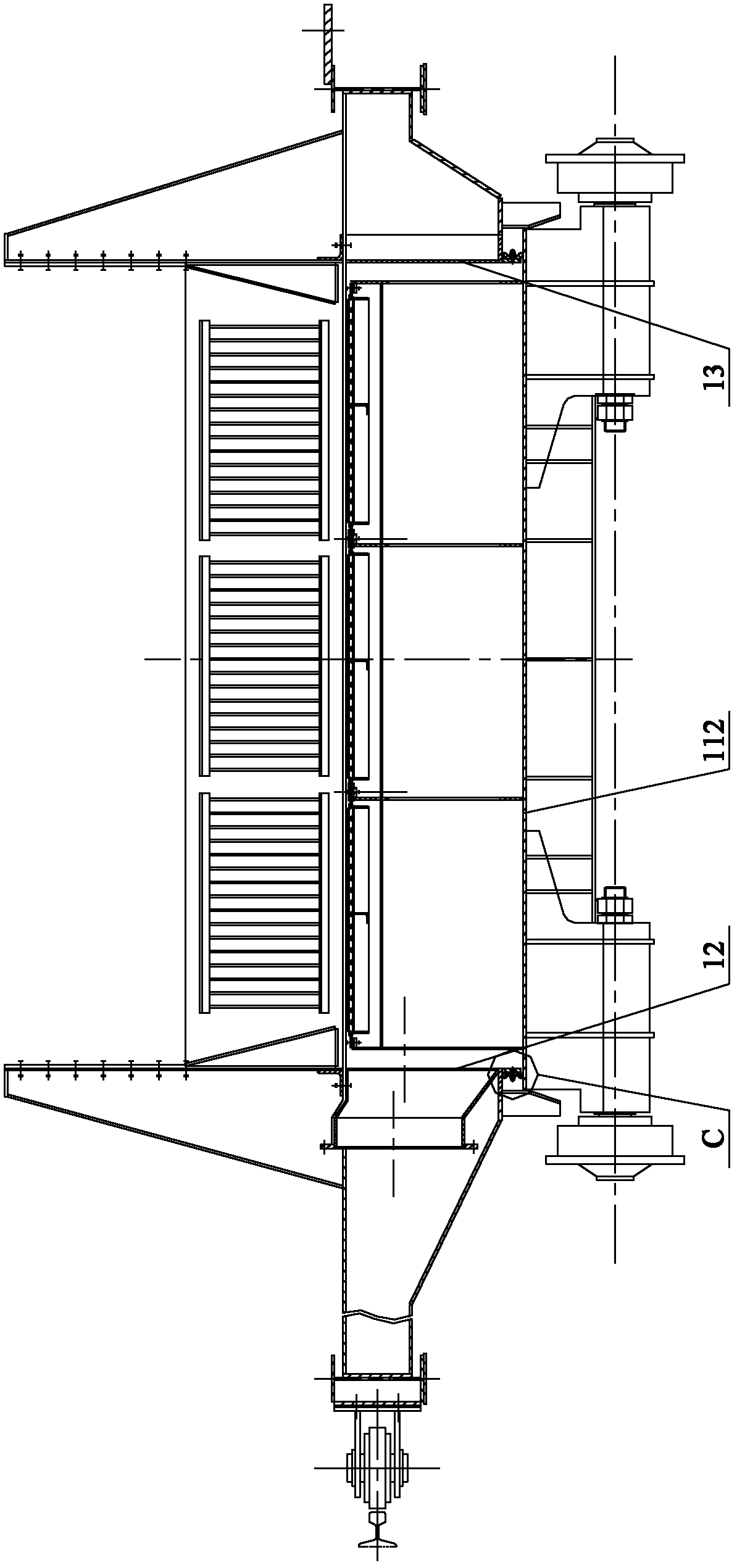

[0038] The core of the present invention is to provide a unit static sealing device with optimized structure to effectively solve the problem of residual minerals trapped between the sealing element and the lower plate of the trolley, and to ensure the working stability of the whole machine.

[0039] Without loss of generality, this embodiment will be described in detail below in conjunction with the accompanying drawings of the specification.

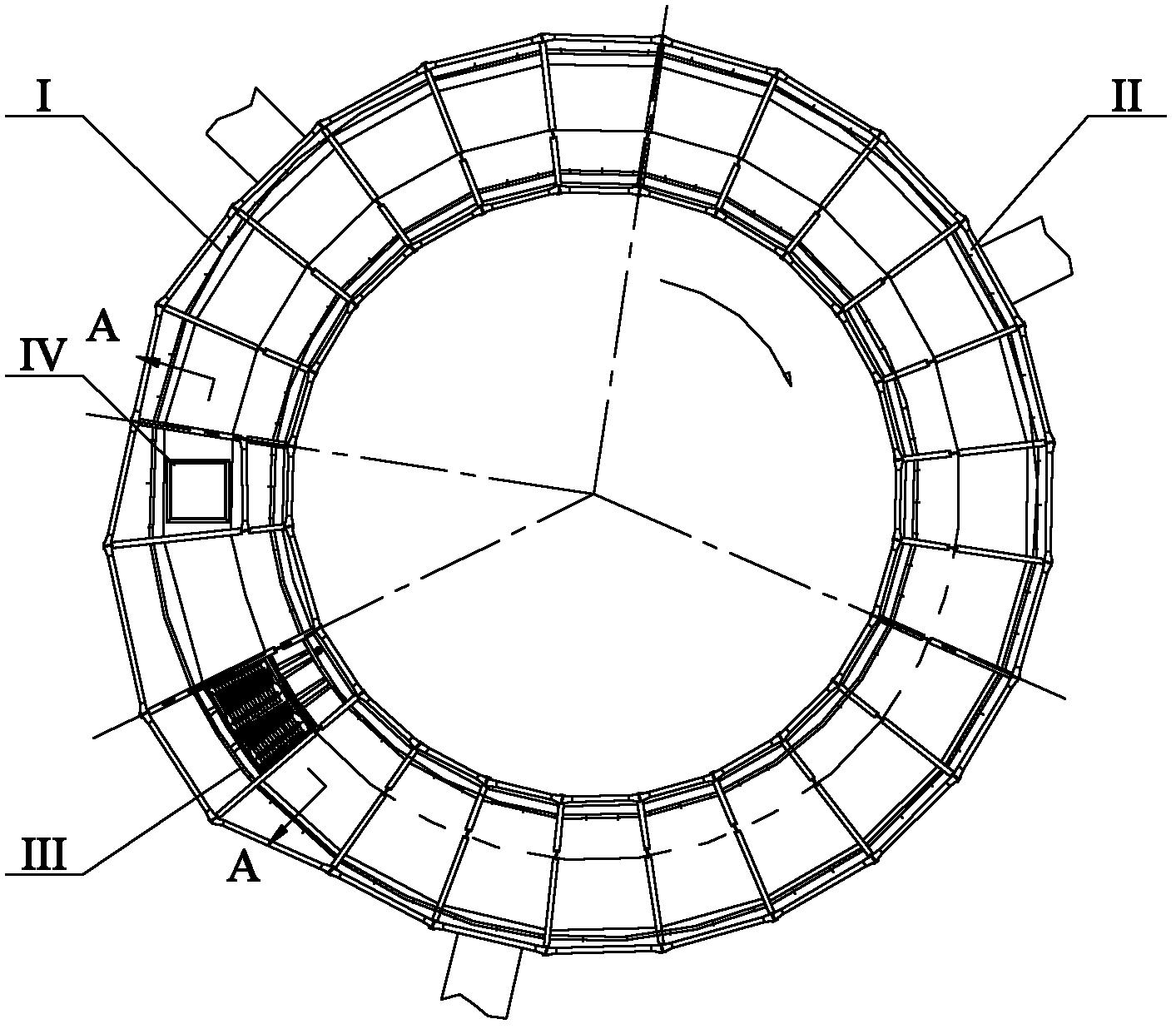

[0040] In this article, the orientation words inside and outside used for the inner sealing plate of the trolley and the outer sealing plate of the trolley are defined based on the center of the ring cooler, and the front and back of the relevant position words are the rotation of the ring cooler. The direction is defined on the basis. It should be understood that the use of the localizers such as inside, outside, before, and after does not limit the scope of protection claimed in this application.

[0041] In this embodiment, the basic func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com