Cutting, stacking, feeding and rolling integrated domestic film production device

A production device and film stacking technology, which is applied in the directions of sending objects, winding strips, folding thin materials, etc., can solve the problems of not realizing the integration of RO film roll-cutting film, film layer clamping and conveying, etc., to improve production. Efficiency and product quality, improving production efficiency, avoiding missed or misplaced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

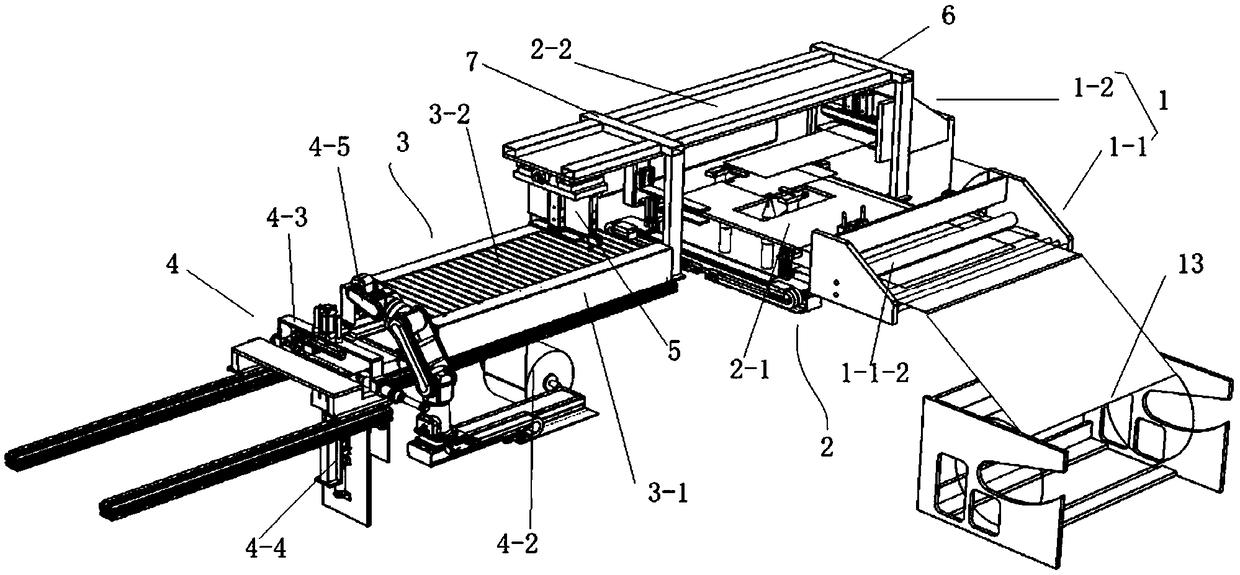

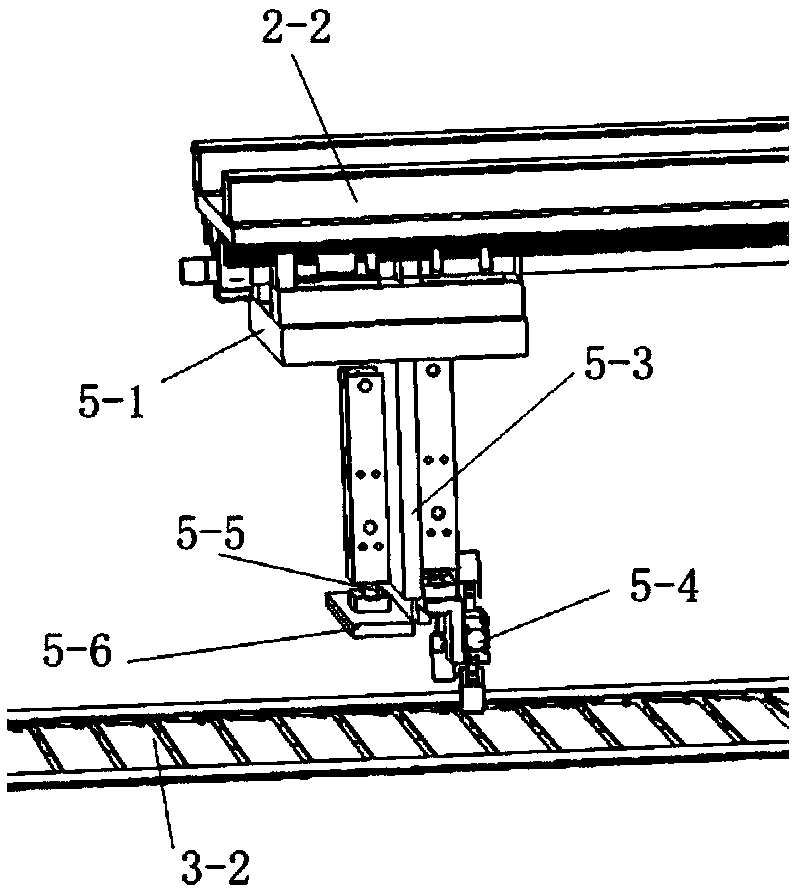

[0041] Such as figure 1 As shown, an integrated household film production device for cutting, stacking, feeding and rolling includes a slitting mechanism 1, a film lamination mechanism 2, a conveying mechanism 3, and a film rolling mechanism 4. The slitting mechanism 1 and the film lamination mechanism 2 A feeding conveying member is arranged between the laminated film structure and the conveying mechanism 3 is arranged with a discharging manipulator 5, and the film rolling mechanism 4 is placed under one end of the conveying mechanism 3 away from the laminated film structure. The slitting mechanism 1, the film lamination mechanism 2, the conveying mechanism 3 and the film rolling mechanism 4 are all connected to a control unit, and the control unit adopts a PLC controller.

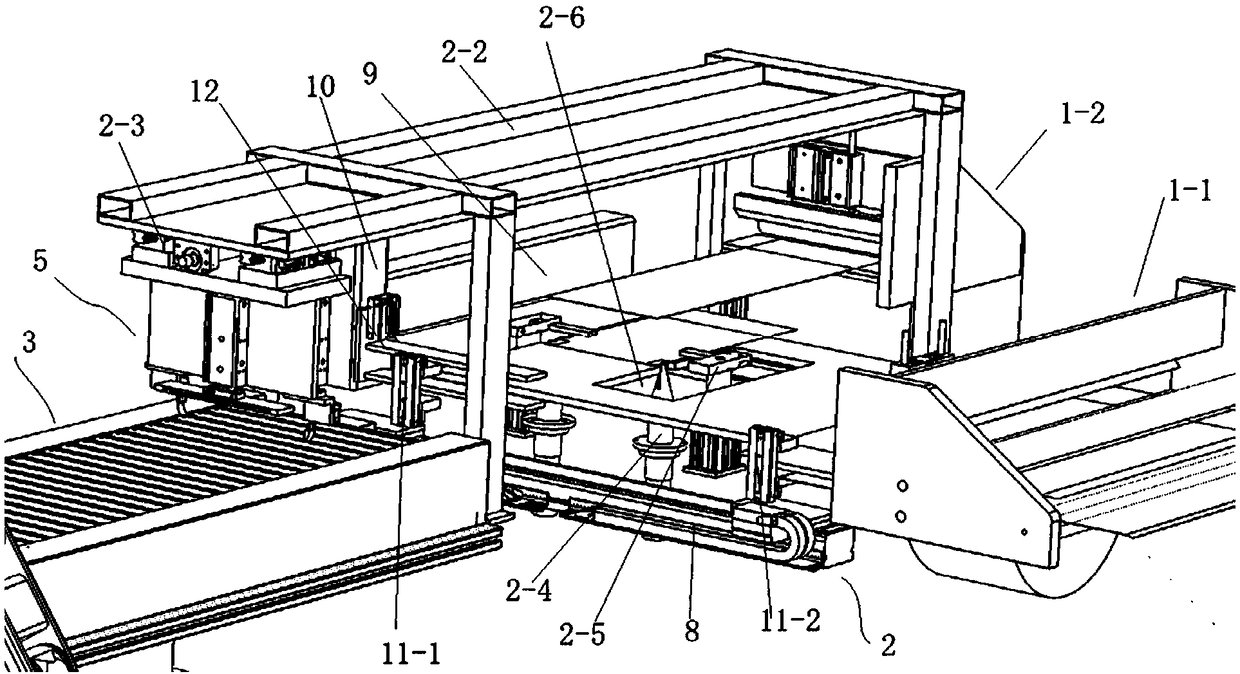

[0042] Such as Figure 2-3 As shown, the laminating mechanism 2 includes a laminating workbench 2-1, a blanking support plate 2-2 is provided above the laminating workbench 2-1, and a lower end of the blankin...

Embodiment 2

[0054] Such as Figure 1-6 As shown, this embodiment is basically the same as the first embodiment. The difference is that the specifications of the RO film are different, and the number of types of materials involved is also different. According to the number of types of materials involved, the number of slitting mechanisms 1 and the corresponding upper The present embodiment relates to the case where the slitting mechanism 1 includes a first slitting mechanism 1-1 and a second slitting mechanism 1-2.

[0055] Such as figure 1 As shown, the slitting mechanism 1 includes a first slitting mechanism 1-1 and a second slitting mechanism 1-2, and the first slitting mechanism 1-1 and the second slitting mechanism 1-2 are arranged in the The two adjacent sides of the laminated film workbench 2-1, wherein the second slitting mechanism 1-2 is arranged on the upper right side of the laminated film workbench 2-1 through the second vertical support frame 6 Connected to the right end of the ...

Embodiment 3

[0066] Such as Figure 1-6 This embodiment is basically the same as the second embodiment, but the difference is that if the RO film roll is rolled with multiple RO film layers at the same time, a guide cloth layer should be placed between the different RO film layers, so this embodiment is A third slitting mechanism is provided between the second slitting mechanism 1-2 and the blanking support plate 2-2, and the third slitting mechanism includes a third feeding member, and a third feeding member is provided on the third feeding member. Three cutting pieces, the third feeding piece has the same structure as the second feeding piece, and the third cutting piece has the same structure as the second cutting piece, and passes through the second vertical support frame 6 and the blanking support plate 2 -2 The right end is connected; the feed opening of the third slitting mechanism is provided with a guide cloth roll, and the guide cloth layer is realized by the cooperation of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com