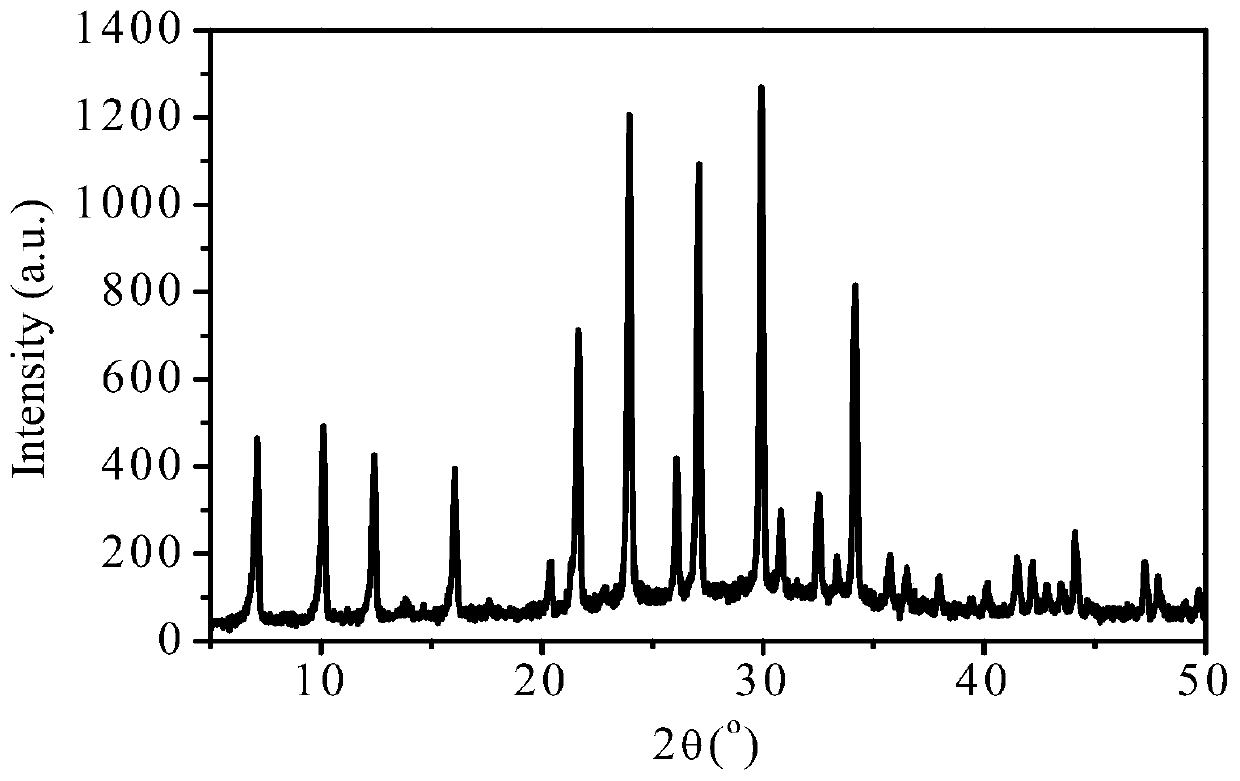

A method for preparing magnetic 3a molecular sieves from coal gangue

A molecular sieve and coal gangue technology, which is applied in the field of 3A type molecular sieve preparation, can solve the problem of high cost synthesis of molecular sieve, and achieve the effects of improving the reuse rate, reducing the crystallization temperature and saving energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

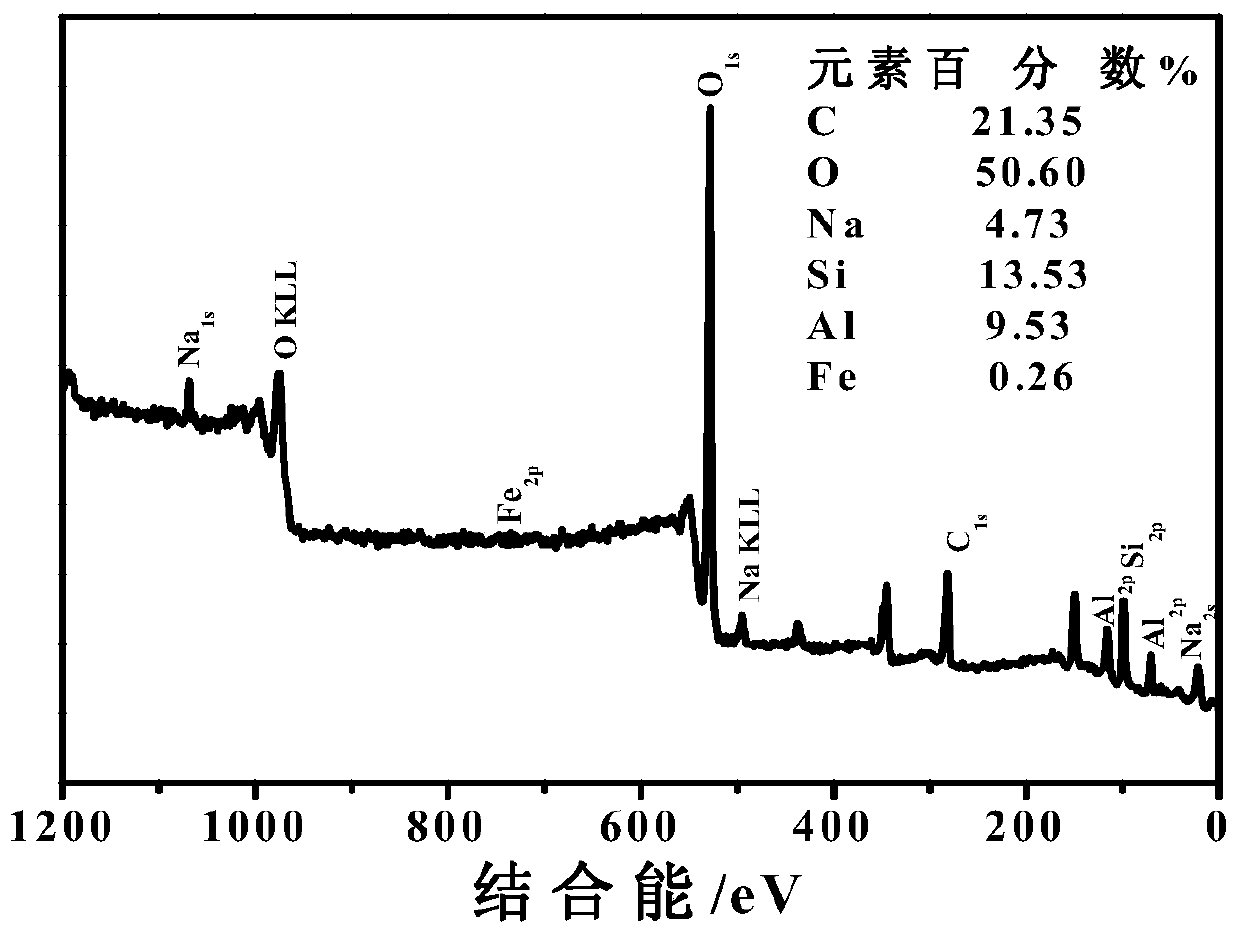

[0031] In the present embodiment, the method for preparing magnetic 3A molecular sieves from coal gangue comprises the following steps:

[0032] Step 1: Grind coal gangue to 315 mesh and place it in the ash dish, then add sodium carbonate to the ash dish, roast for 2 hours at a temperature of 900° C. and then grind to obtain a pretreated sample; the sodium carbonate and coal The mass ratio of gangue is 3:1;

[0033] Step 2. Oxidize the pretreated sample obtained in step 1 at a temperature of 350° C. for 2 hours, then add hydrochloric acid solution, soak for 2 hours at a temperature of 90° C., and filter to obtain a filter residue and a filtrate. The filtrate Contains Fe in hydrochloric acid solution and coal gangue 2 o 3 Dissolved Fe 3+ The mass concentration of the hydrochloric acid solution is 15%, and the consumption of the hydrochloric acid solution is 5mL hydrochloric acid solution for every gram of pretreatment sample; The mol ratio of the deionized water and sodium h...

Embodiment 2

[0045] In the present embodiment, the method for preparing magnetic 3A molecular sieves from coal gangue comprises the following steps:

[0046] Step 1: Grind the coal gangue to 315 mesh and place it in the ash dish, then add sodium carbonate to the ash dish, roast for 2.5 hours at a temperature of 890° C. and then grind to obtain a pretreated sample; the sodium carbonate and The mass ratio of coal gangue is 2.5:1;

[0047] Step 2. Oxidize the pretreated sample obtained in step 1 at a temperature of 375° C. for 1.8 hours, then add hydrochloric acid solution, soak for 2.5 hours at a temperature of 95° C., and filter to obtain a filter residue and a filtrate. The filtrate contains Fe in hydrochloric acid solution and coal gangue 2 o 3 Dissolved Fe 3+ ; Fe in the hydrochloric acid and filtrate 3+ The mol ratio of the hydrochloric acid solution is 5:1; the mass concentration of the hydrochloric acid solution is 15%, and the consumption of the hydrochloric acid solution is 5mL ...

Embodiment 3

[0053] In the present embodiment, the method for preparing magnetic 3A molecular sieves from coal gangue comprises the following steps:

[0054] Step 1. Put the coal gangue into the ash dish after grinding it to 300 mesh, then add sodium carbonate to the ash dish, roast for 3 hours at a temperature of 850° C. and then grind to obtain a pretreated sample; the sodium carbonate and coal The mass ratio of gangue is 2:1;

[0055] Step 2. Oxidize the pretreated sample obtained in step 1 at a temperature of 400° C. for 1.5 hours, then add hydrochloric acid solution, soak for 3 hours at a temperature of 90° C., and filter to obtain a filter residue and a filtrate. The filtrate Contains Fe in hydrochloric acid solution and coal gangue 2 o 3 Dissolved Fe 3+ ; Fe in the hydrochloric acid and filtrate 3+ The mol ratio of the hydrochloric acid solution is 5:1; the mass concentration of the hydrochloric acid solution is 15%, and the consumption of the hydrochloric acid solution is 5mL h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com