A method for realizing gradient doping of zinc oxide nanowire arrays

A zinc oxide nanowire, gradient doping technology, applied in the direction of zinc oxide/zinc hydroxide, vacuum evaporation coating, coating, etc., can solve the problems of small space size of nanowires, and achieve the effect of reliable preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

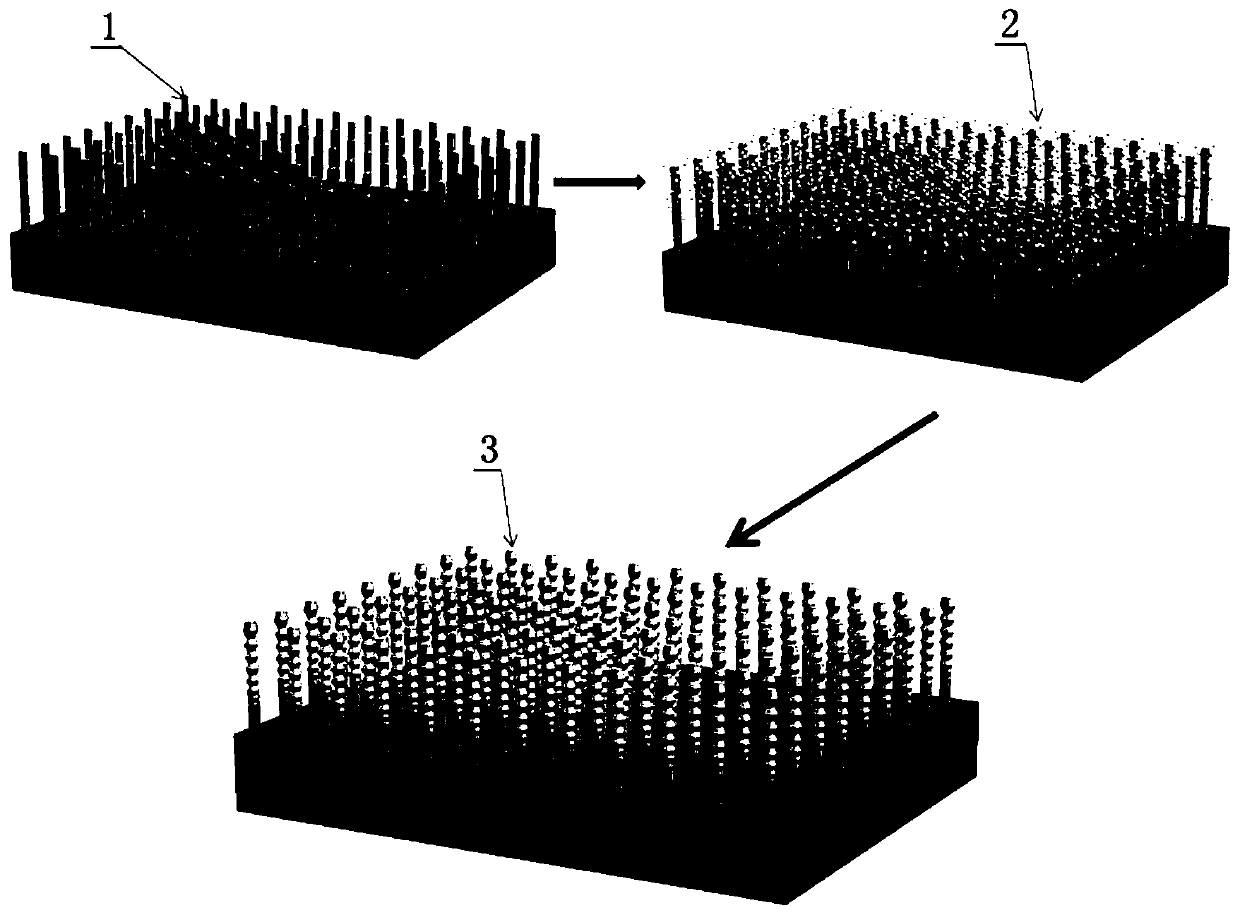

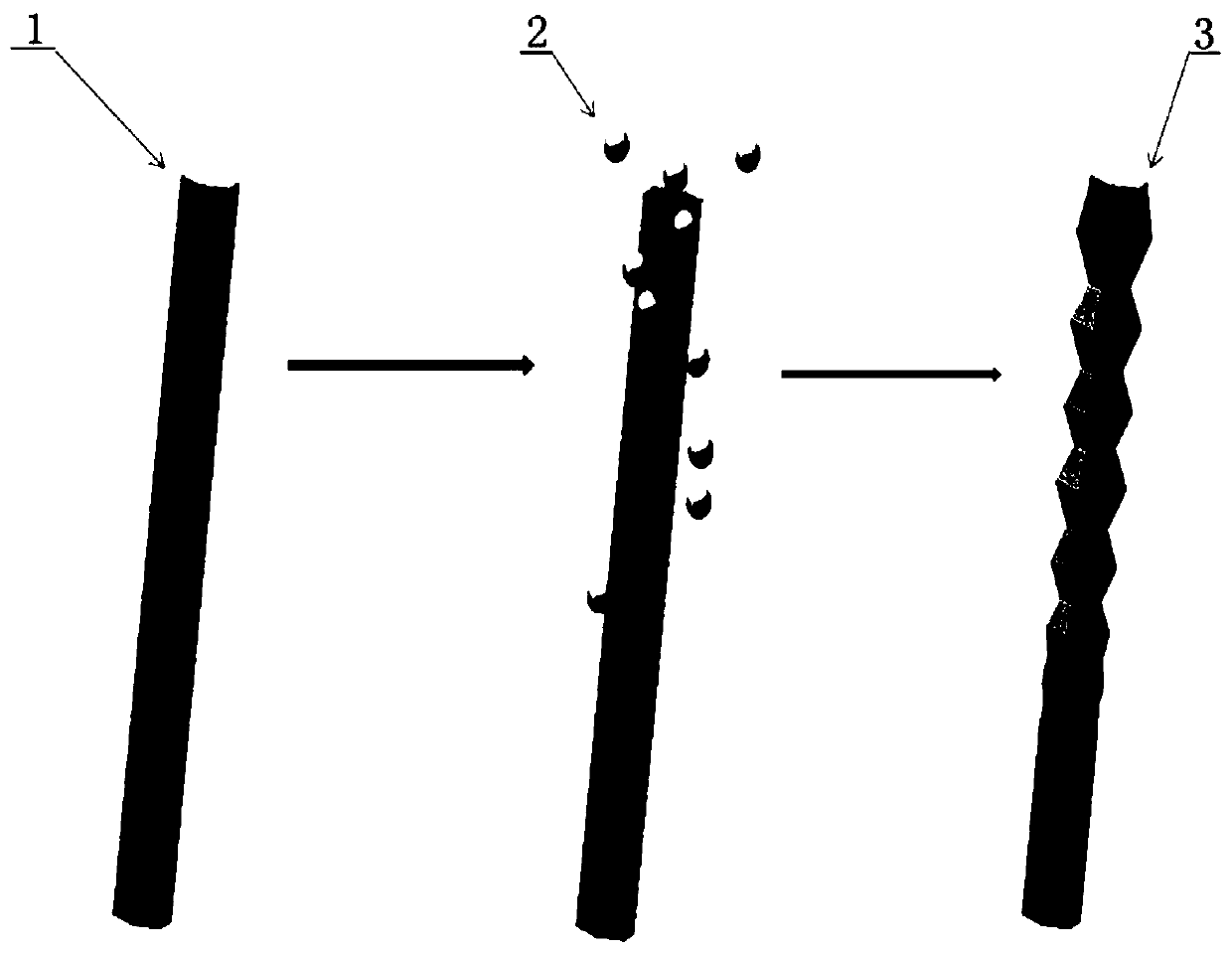

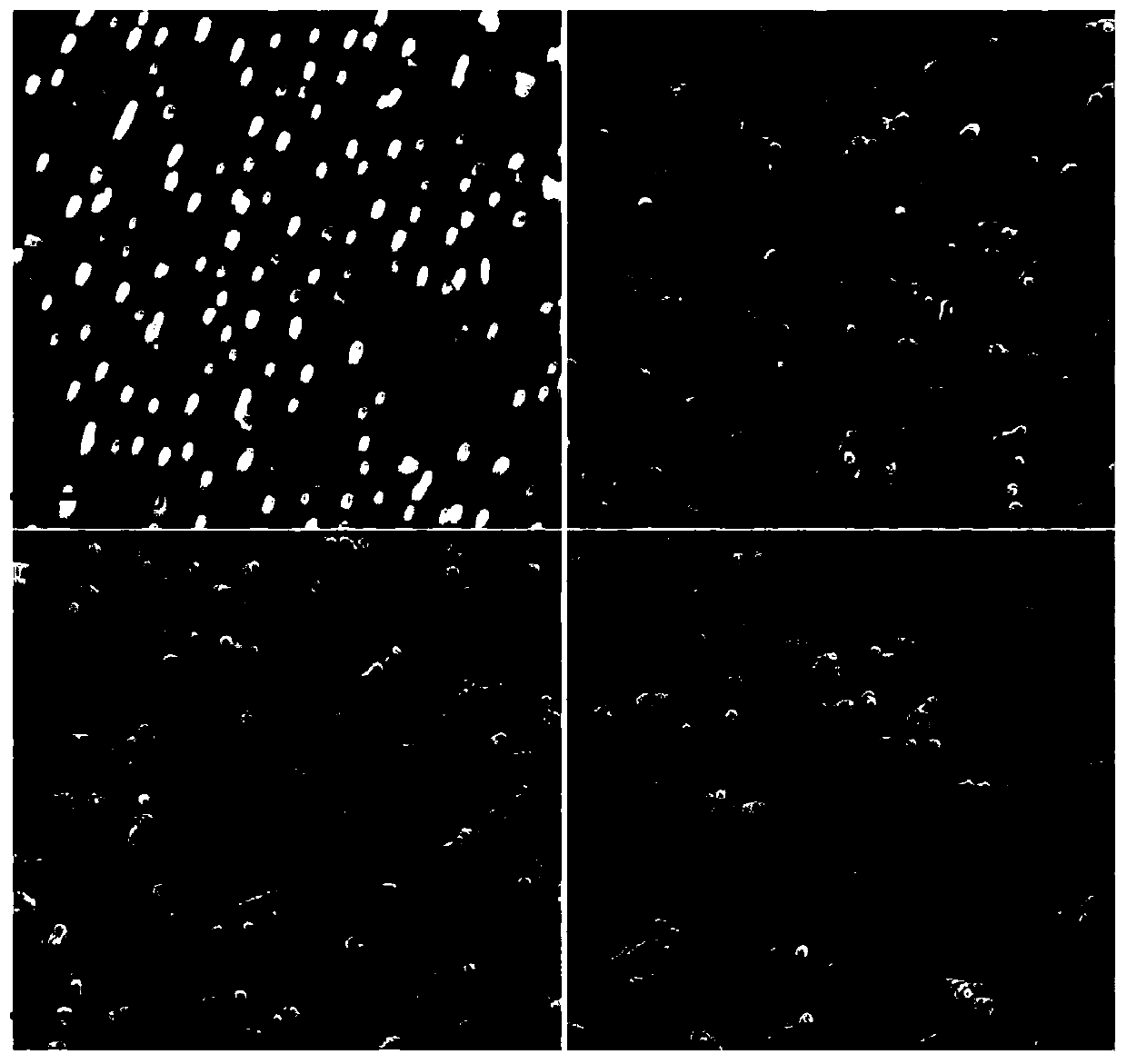

[0042] see Figure 1-7 , a method embodiment 1 of the present invention for realizing gradient doping of zinc oxide nanowire arrays, comprising the following steps:

[0043] (1) Select a 0.5×0.5 cm gallium nitride conductive substrate, ultrasonically clean it with ethanol, acetone and deionized water for about 10 minutes, and then dry it with dry nitrogen to prepare a deposition substrate.

[0044] (2) Evaporate a layer of gold film with a thickness of 5nm on the cleaned gallium nitride conductive substrate by using an electron beam evaporation coating apparatus, as a catalyst for the growth of zinc oxide nanowires.

[0045] (3) Weigh zinc oxide powder and carbon powder according to a mass ratio of 1:1, mix them and grind them evenly to make a mixed powder, the purity of the zinc oxide powder is ≥99.9%, then weigh 0.13g of the mixed powder as a reaction source and place it in a dual temperature zone At the closed end of the inner tube of the tube furnace, the deposited substr...

Embodiment 2

[0056] Embodiment 2 of a method for realizing gradient doping of zinc oxide nanowire arrays according to the present invention comprises the following steps:

[0057] (1) Select a 0.5×0.5 cm gallium nitride conductive substrate, ultrasonically clean it with ethanol, acetone and deionized water for about 10 minutes, and then dry it with dry nitrogen to prepare a deposition substrate.

[0058] (2) Evaporate a layer of gold film with a thickness of 5nm on the cleaned gallium nitride conductive substrate by using an electron beam evaporation coating apparatus, as a catalyst for the growth of zinc oxide nanowires.

[0059] (3) Weigh zinc oxide powder and carbon powder according to a mass ratio of 1:1, mix them and grind them evenly to make a mixed powder, the purity of the zinc oxide powder is ≥99.9%, then weigh 0.13g of the mixed powder as a reaction source and place it in a dual temperature zone At the closed end of the inner tube of the tube furnace, the deposited substrate coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap