Pneumatic structure of shuttle

A shuttle and cylinder technology, applied in the field of shuttle pneumatic structure, can solve problems such as easy problems, high maintenance cost, complex structure, etc., and achieve the effects of simple structure, beautiful appearance, reliable and flexible action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

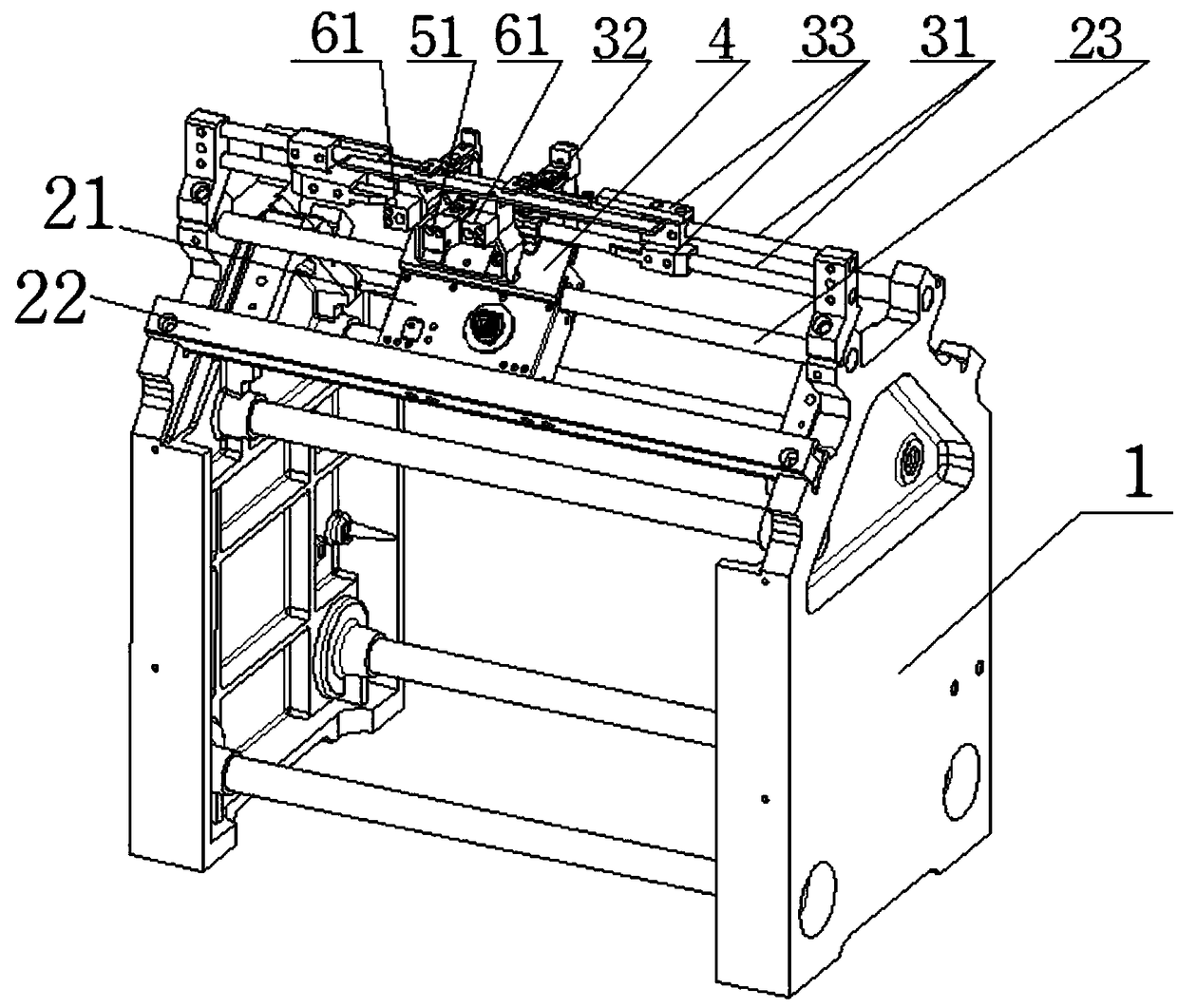

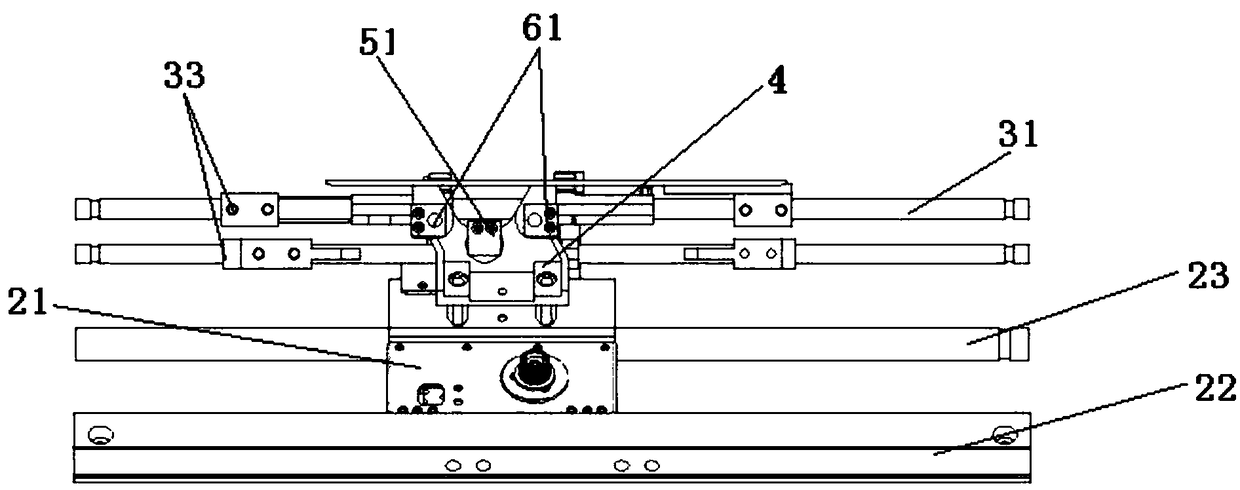

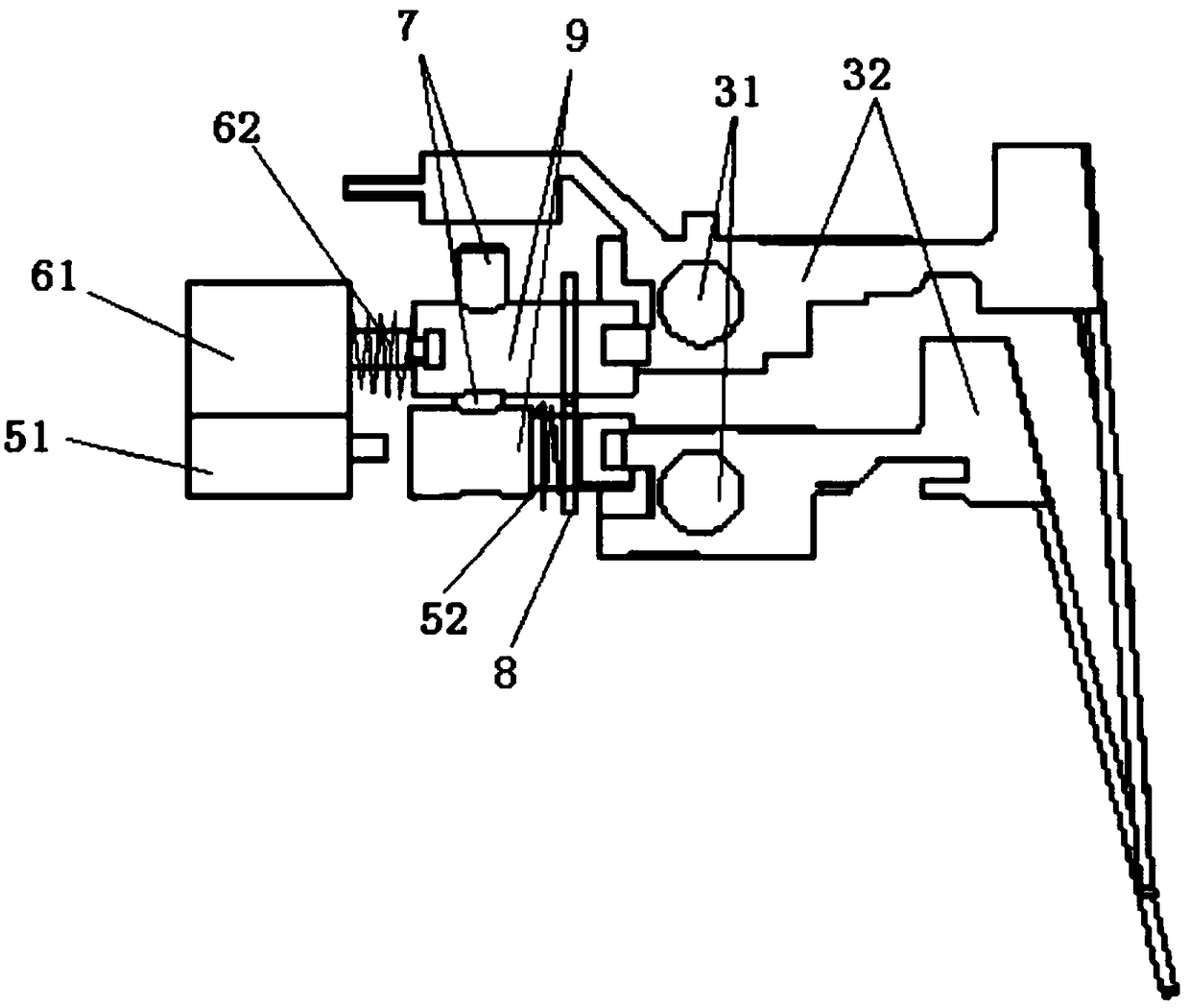

[0028] Combine below Figure 1-4 Further explanation: a shuttle pneumatic structure, including a mounting bracket 1, a cylinder (the figure shows the situation that both the pull cylinder 61 and the push cylinder 51 are used, the middle one is the push cylinder 51, and the two sides are pull cylinders 61), Shuttle driving shaft 9, head shaft frame, head shaft 23, head chute 22, shuttle assembly 32, head 21 and shuttle shaft 31, and described mounting frame 1 is provided with head shaft 23 and head chute 22 , the upper part of the machine head 21 is installed on the machine head shaft 23 through a sliding connection, the lower part of the machine head 21 is slidably connected with the machine head chute 22 through the bearing 24, and the machine head is installed on the upper part of the machine head 21 Pedestal 4, a cylinder is installed on the head spindle frame 4, a shuttle drive shaft 9 is provided on the head spindle frame 4, and the shuttle drive shaft 9 and the cylinder ...

Embodiment 2

[0039] Others are all the same as in Embodiment 1, except that there are two pulling cylinders and three pushing cylinders.

Embodiment 3

[0041] Others are all the same as in Embodiment 1, except that there are three pulling cylinders and no pushing cylinders.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com